This week I’ve written a few stories about Stratasys’ new J750, and here’s more thoughts on what this milestone machine means for others in the 3D print universe.

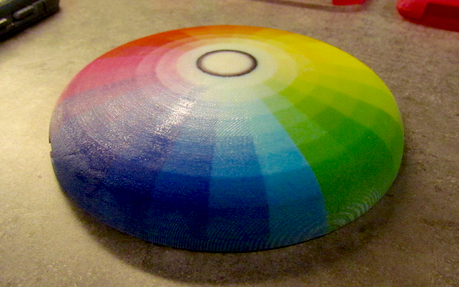

When something new arrives on the scene, there are bound to be ripples in the existing order. Relationships, usage patterns and costing all could be disturbed. I believe that will be the case with the J750, which is a device that can 3D print full color, textured, multimaterial objects that are highly realistic.

The most obvious affected parties could be those vendors providing color 3D printers, of which there are two prominent members: 3D Systems and MCOR.

3D Systems provides several full-color 3D printers, all based on the original ZCorp process that involved coloring and fusing fine plastic powder. The prints from the 3D Systems machines have long been a standard in industry for producing color 3D prints. However, these prints are much like “sandstone” when completed: they don’t flex, they don’t include transparent features and the color is a bit muted as compared to that of the J750.

While the 3D Systems machines can still produce good color prints, they are not as versatile as those of the J750. Thus, the J750 will be of greater interest to some buyers.

The other color 3D print option is MCOR’s Arke, a new paper-based 3D printer that produces solid, good color prints. But like the 3D Systems process, MCOR’s also produces parts without flexibility and transparency, thus limiting their use as compared to the J750.

One advantage both the 3D Systems and MCOR equipment may have over the J750 is price, particularly MCOR’s unit, which operates at very low cost (relatively speaking), as it uses paper, color ink and glue for its print material.

Another area of change will most likely be within 3D print service bureaus. I learned the cost of the J750 will be at “premium levels”, which could mean that many businesses interested in using the device might not be able to afford one on their own.

But they could buy J750 prints from a 3D print service bureau, if a bureau was equipped with a J750 or two. It seems to me that it might be a good idea for some bureaus to make plans for J750 equipment and product line.

One more area of change could be 3D software makers, who now will face increased demand for color 3D modeling capabilities. Sure, there are several such software packages and services that can handle color 3D models today, such as Adobe Photoshop, but my point is that there should be more. A great many tools assume monocolor objects, but at least a few of them should consider adding color capability.

Similarly, few tools offer the ability to specify flexible components, and the ability to select degrees of flex. This is a feature that could be considered in future releases.

Further on software, it’s possible those already with color software might provide more specific integration with the J750 to simplify the color 3D printing workflow. If life’s easier with the J750, you might see more usage of the software.

But these are mere speculation; it remains to be seen how the rest of the 3D printing industry will react to the incredible J750. It’s also possible we might see a competing color multimaterial 3D printer from another vendor, but I suspect we will have to wait quite a while for that.

Via Stratasys