Yes, we’ve all seen carbon fiber 3D printing material, but now scientists from the University Of California have managed to use carbon dioxide to 3D print.

Of course, they’re not using it in gaseous form, which would obviously not work, although if under sufficient pressure, you might hear a pleasant whistle as the gas blows through your hot end.

No, instead they’re using carbon dioxide in a process to produce a form of portlandite, or concrete. They call it “Co2ncrete”. Their chemical process works like this:

The objective of the project is to capture excess carbon dioxide released from dirty power plants and transform it into building material as an attack on carbon-related climate change.

I believe this is a very strong idea, because the normal concrete displayed by co2ncrete generates spectacular amounts of CO2 into the atmosphere. It’s really double the carbon value: removal from the air and prevention of additional generation.

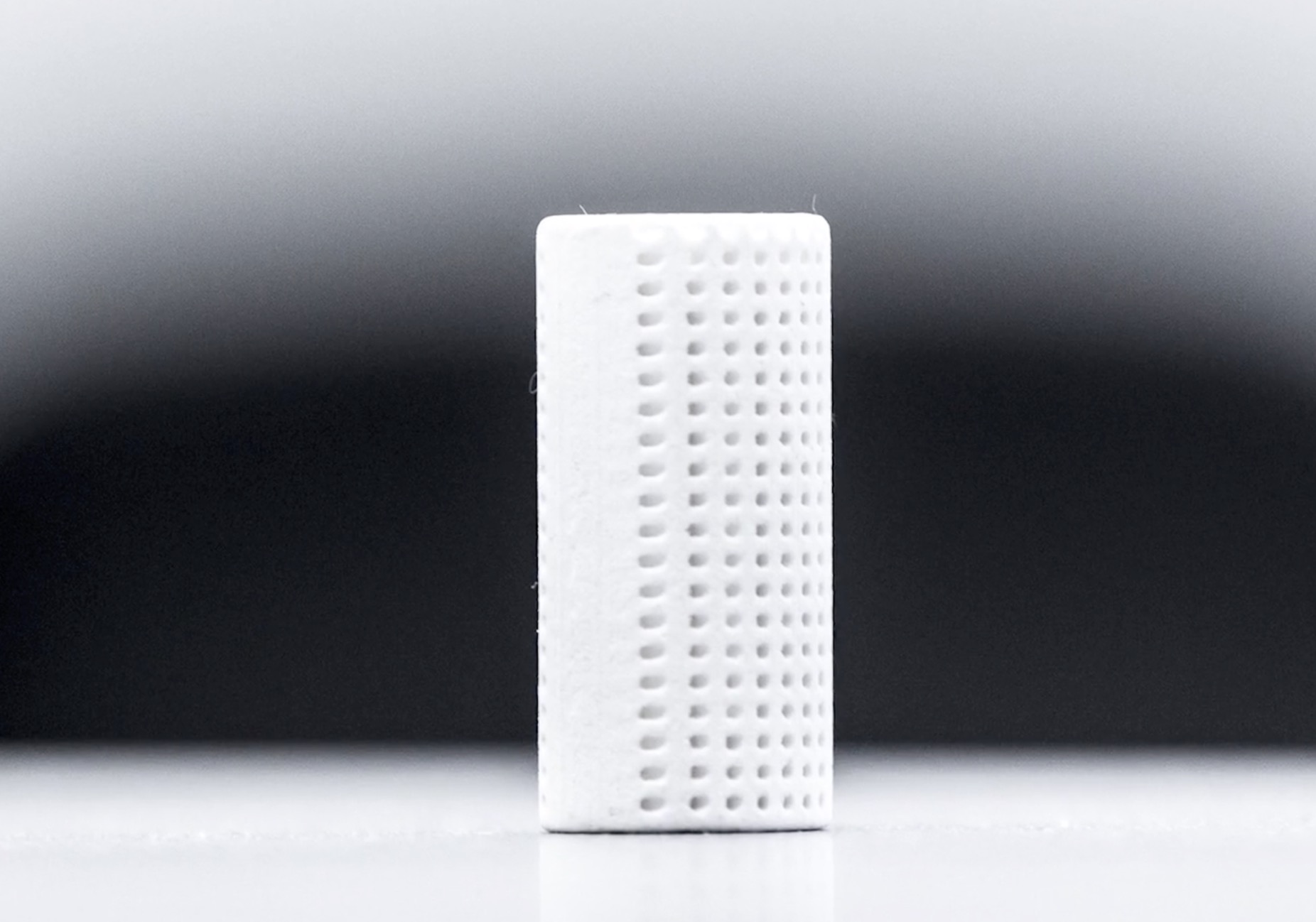

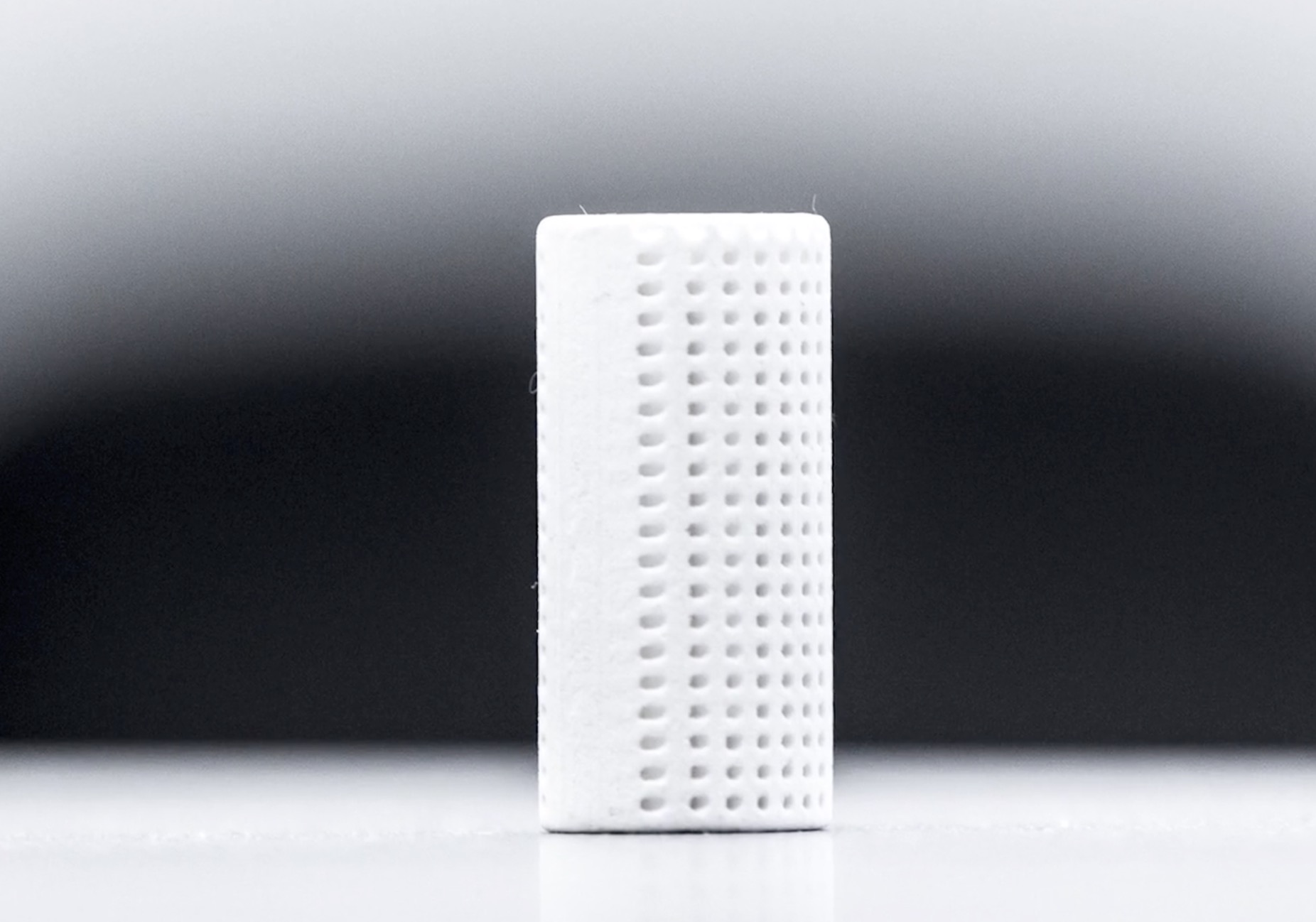

The researchers have also managed to 3D print small items with this material, as shown at top. Of course, such small prints will have no effect on global carbon counts, but the hope is that co2ncrete would also be used as a building material for roads and large structures in addition to 3D printing.

It’s not clear how they accomplished the 3D printing, but I suspect they simply used a syringe-based extrusion technique in which a mix of dry co2ncrete and binder were pushed through a nozzle. It may also be possible to mix dry co2ncrete with water as you might do with cement, but pushing that through an extruder would be a risky prospect, as you face the possibility of an extruder jammed with concrete!

For 3D printing, this development is not likely to become a big thing, but I’m hoping it does for non-3D applications, such as roads, where it could make a difference to our future world.

Via ACS