As the emphasis on 3D printing shifts from poorly adopted consumer applications to industrial uses, 3D printer companies must find ways to make this shift. Airwolf has found a very effective and fun way to do so.

“Turning On” a company to 3D printing is not as easy as you might think. There are many companies still not using 3D printing, largely because of lack of knowledge, fear of change, financial challenges, uncertainty of applicability and other factors. For 3D printer companies wishing to make increased sales, it is critical for them to find ways to get more companies using 3D printing.

Some manufacturers, like Stratasys, have developed whole divisions dedicated to industry verticals, like dental or aerospace, with specialists on hand to show how it’s done to newbie users.

But Airwolf’s approach is quite different, and perhaps, more effective: an in-house hackathon.

The concept is similar to other “pop-up” style marathons, in which something is built within a limited time period. It might be a short movie, a type of machine or even a small business, all built from scratch in a fixed period, usually for prizes or fame.

The benefit of this approach is that the participants are all placed in the same competitive scenario; they’re equals and face a very clear and common goal. It causes people to work together in a cooperative manner and learn what it takes to get the project done.

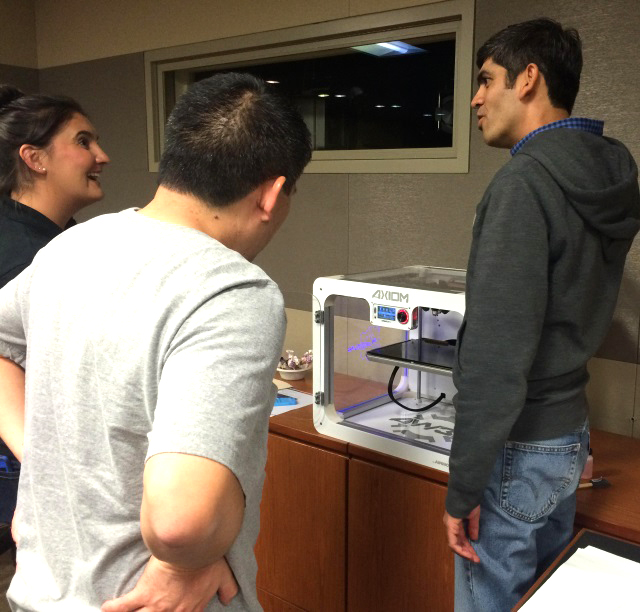

That’s what Airwolf recently did with Warner Bros in Hollywood, a company wishing to get more of their staff using 3D printing technologies. Participation in the voluntary hackathon was made available to all staff.

According to Airwolf, the hackathon accomplished that:

-

It quickly identified key pioneers at the company with the desire to learn and embrace 3D printers in their workplace.

-

It avoided feelings of a new technology being “forced” on staff.

-

Prevented the potential financial burden of placing additive manufacturing equipment in departments where it might simply collect dust.

-

It was a positive team building experience, filled with creativity, innovation and cross-collaboration among various departments.

At the end of the event, all participants had actually experienced 3D printing technology in some detail, making them ready to do more without many of their original concerns.

And, for Airwolf this is a big thing because these participants were using equipment provided by Airwolf. They’re now quite familiar with operating Airwolf’s AXIOM machines and are perhaps considering buying several for their business.

It’s a great move by Warner Bros and Airwolf, as it made a real change in the attitude towards 3D printing in a company. And it’s probably a lot less expensive to do than Stratasys’ approach.

Much more of this must be done with other companies still struggling with the concept of 3D printing.

Via Airwolf