It seems that the elements required to enable the 3D printing of incredibly complex structures we’ve all long imagined are slowly coming together.

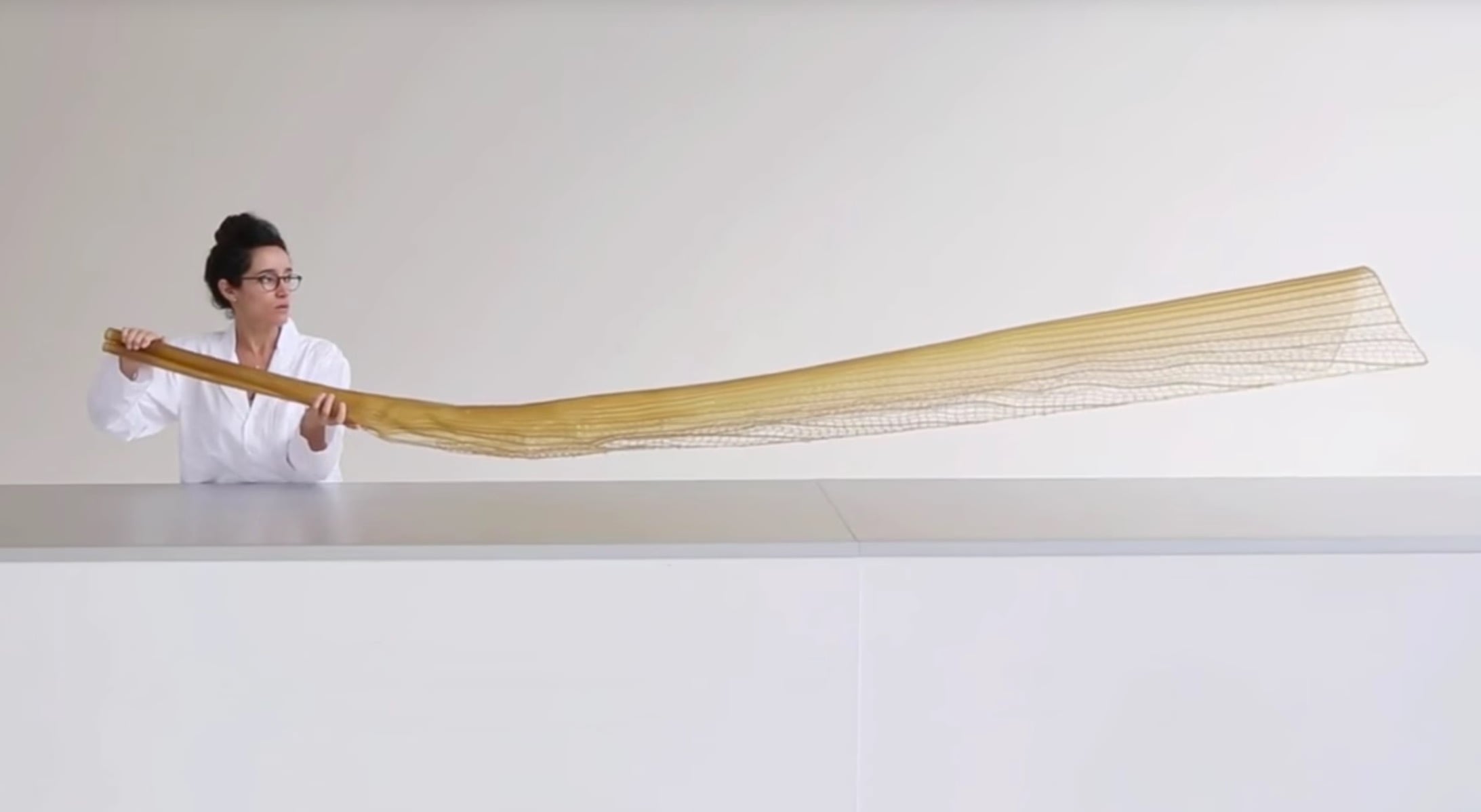

A long read at Surface Mag on the work of Prof. Neri Oxman, Head of the Mediated Matter research group at the MIT Media Lab reveals some of the work that’s heading in that direction. Oxman’s work has explored the differences between the traditional mechanical methods of construction versus that used by organic processes in nature.

These two approaches are wildly different, but each effective in their own way. Oxman hopes to bridge the gap between them by leveraging two relatively new technologies: 3D printing and computational design.

Readers will be familiar with 3D printing concepts, but you may not be familiar with computational design, defined by Wikipedia as:

Generative design is a design method in which the output – image, sound, architectural models, animation – is generated by a set of rules or an Algorithm, normally by using a computer program.

This is very different from traditional design, which involves discrete components. Meanwhile computational design (or generative design, as Wikipedia refers to it) seems to develop the very complex patterns we’ve seen in nature by not only continuously varying the shape of the structures, but also the material mix at every step.

Oxman explains these differences in some detail in her notable 2015 TED talk:

But now it appears we may be reaching the point where such experiments could become actual building projects in the near future. According to the report on Surface Mag:

Her next challenge: to step outside of the laboratory and apply her research to an architectural scale. Although Oxman has previously worked for firms both in Israel and the U.K., she has never led the construction of a large-scale building, nor has she run her own architectural practice. But she has a leg up: The necessary specialized software and 3-D printers she uses are available to only a small fragment of the world’s architects and designers. “I’m starting to be hungry for the architectural scale,” she says, “to some of my mentors’ chagrin. We’re at a point where big companies are starting to express keen interest in some of our technologies, and the need to shift scales becomes inevitable.” More practically, it would require her to establish a parallel professional domain, potentially outside of the academic world, with a team of designers that can not only code and research, but also lay out plans, draw facades, and build.

World renowned architect Moshie Safdie adds:

Neri is currently allowing the ingenuity of the materials she explores to drive the aesthetics of her design. However, when she makes the jump to the building scale, she will have to cope with multiple systems and to fully control their composition.

And this is always the case: the devil is in the details. While we’ve seen some primitive experiments creating 3D printed structures, most of them are unscalable, offer no particular advantages over conventional construction, are feasible only in certain conditions or are outright scams.

The work Oxman has been doing may be able to eventually overcome such barriers by leveraging the long-developed techniques in nature.

It wouldn’t be surprising to see an announcement with a major firm partnering with Oxman and team to attempt such works on a much larger scale.

If successful, it could lead to a very fundamental transformation in how we live, work and consume energy, as the power of computational design could permit revolutionary structures offering functions far beyond mere walls.

Via Surface and TED (Hat tip to Blake)