With the worlds of 2D and 3D printing starting to blend together, the world’s largest printing equipment exhibition, drupa, is starting to see 3D printer manufacturers demonstrating their wares to drupa attendees.

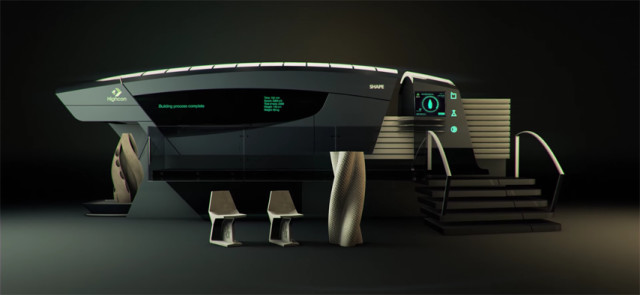

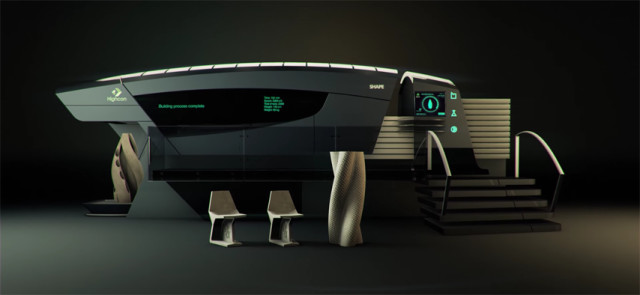

While Israel’s Massivit 3D showcased its enormous gel dispensing printer at the event, fellow Israeli manufacturer Highcon had its own massive machine on display using a medium familiar to the drupa crowd: paper.

Highcon is a digital creasing and cutting company, manufacturing equipment that fold and slice pieces of paper into three-dimensional objects. You know those ornate gift boxes they sell at your local big box store? Or those pop-up greeting cards from those fancy paper supply shops? Those could very well be made by a creasing and cutting machine.

The company does not go into too much detail about exactly how its massive Shape machine will work. Based on the video below, it looks as though Shape might be based on Highcon’s existing creasing and cutting technology, and could employ methods similar to those used by world’s only other paper 3D printing company, Mcor.

The process of creasing and cutting intricate paper packaging is an interesting one, not too dissimilar from existing 3D printing technologies. Stacks of paper are loaded into the machine at one end and pass through each step of the production process on a conveyor belt.

Layer information, similar to the slices found in a 3D printable file, is written onto a piece of foil, which is automatically placed onto the first sheet of paper in the stack. The machine then applies a special polymer onto the foil. A curing process causes the polymer to harden into raised lines that become the creases of the ultimate product.

Once this process is complete, an array of CO2 lasers cut out the paper design so that, when the sheet comes out of the system, the design can be popped out of the paper and folded into the final product. The complete process can be seen in the video below:

Read more at ENGINEERING.com