Stratasys has partnered with automaker Daihatsu to offer consumers the ability to customize their vehicle using 3D printing.

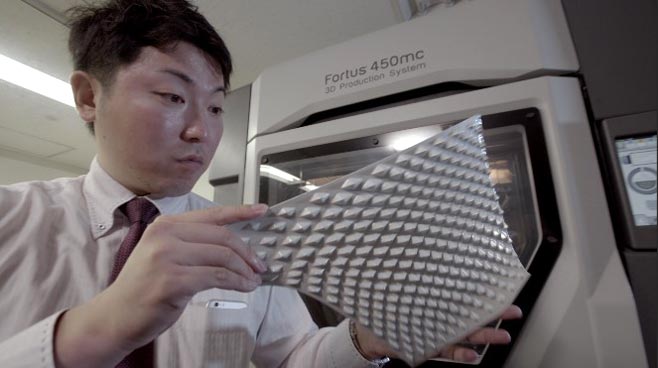

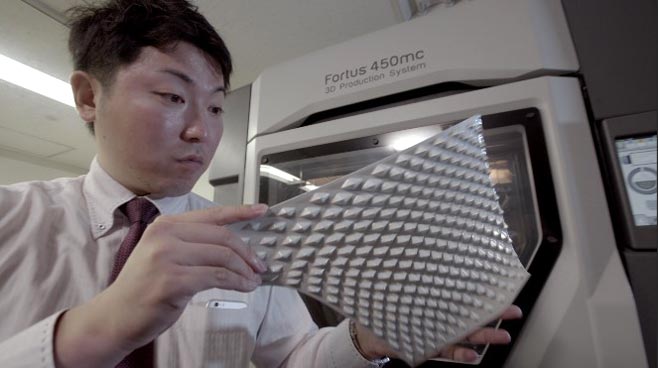

The actual customization is quite small: it’s small panels affixed to the bumper and front and rear of the two-door convertible “Copen” model.

In the new scheme, Daihatsu customers purchasing the vehicle will be able to select from fifteen different pre-made designs and in ten different colors, which match vehicle color patterns.

Wait, why do this when you could simply manufacture quantities of each panel using traditional means and then paste the right ones on the car when the client selects? It’s because these panels have intricate designs that would be challenging to manufacture using regular processes. The likely volume of each pattern would no doubt jack up the cost beyond what customers could withstand, as the cost of tooling setup would have few units to cover the cost.

Enter 3D printing, where such panels could be produced easily on a one-off basis. In fact, there’s nothing saying Daihatsu sticks with only fifteen patterns. They could make many more styles, but the problem is likely that the marketing materials provided to dealers can’t keep up with the flexibility of the 3D printing system!

So are we really customizing a car here? Yes, just slightly. But it is actually quite a milestone: this is perhaps the first time a major company with a notable product has integrated 3D printing for customization into the production workflow.

Stratasys has accomplished this by providing Daihatsu with their Fortus production 3D printer technology, which is certainly capable of running 24×7 producing these panels. I also note that the in spite of the seemingly complex design of the panel, it appears to be a relatively simple and quick print. Smart!

The material used is their ASA plastic, which should be sufficiently durable for this type of outdoor use.

Customizing more of the vehicle will be challenging, as there are so many considerations: safety, appearance, efficiency, repairability, functionality and more. I suspect this type of customization will be limited to cosmetic aspects as done in this project for quite a while.

Via Stratasys