3D print service Sculpteo undertook a comprehensive survey of their clients earlier this year and today they publish the results.

Sculpteo obtained answers from some 1,000 respondents to their second annual survey, who presented a very good cross section of geographical, market and size diversity. In other words, the results of this survey are likely accurate.

But keep in mind this is a survey done for clients of a 3D print service and accounts less for those operating their own 3D printing gear. Nevertheless, the results include some interesting points.

The highlights:

Most prints request plastics as opposed to resins, metals, ceramics or color sandstone. This is likely partly due to price (plastics are cheaper) and that the other materials are still considered specialized and have narrower applications. Correspondingly, Sculpteo’s busiest 3D printers are those that deposit (FDM) or fuse (SLS) plastic.

The survey indicates a number of clients are intending on hiring new staff specifically to perform 3D print-related work. It’s apparently a growth subject in certain companies, companies who likely perceive a competitive advantage to using 3D printing.

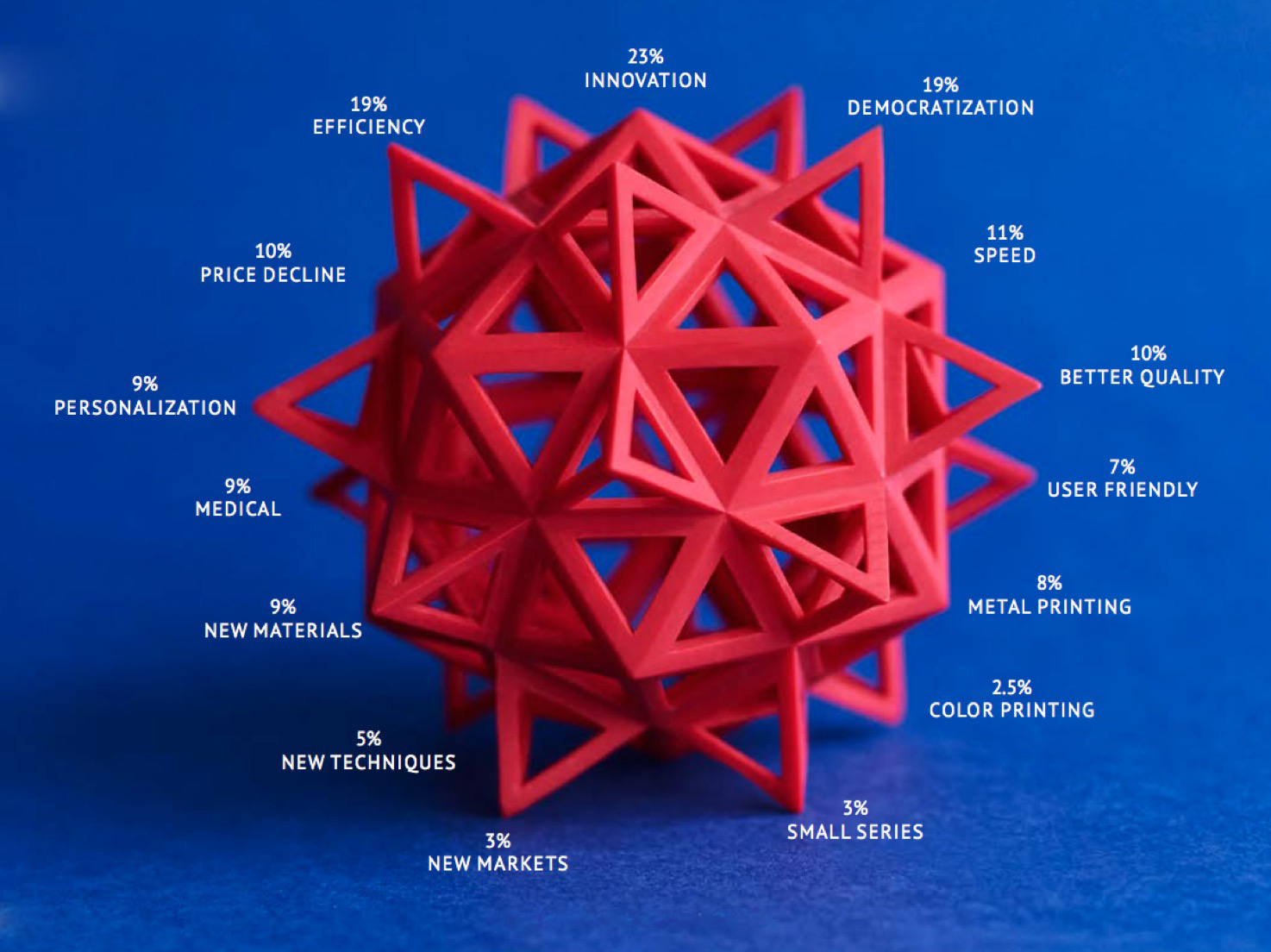

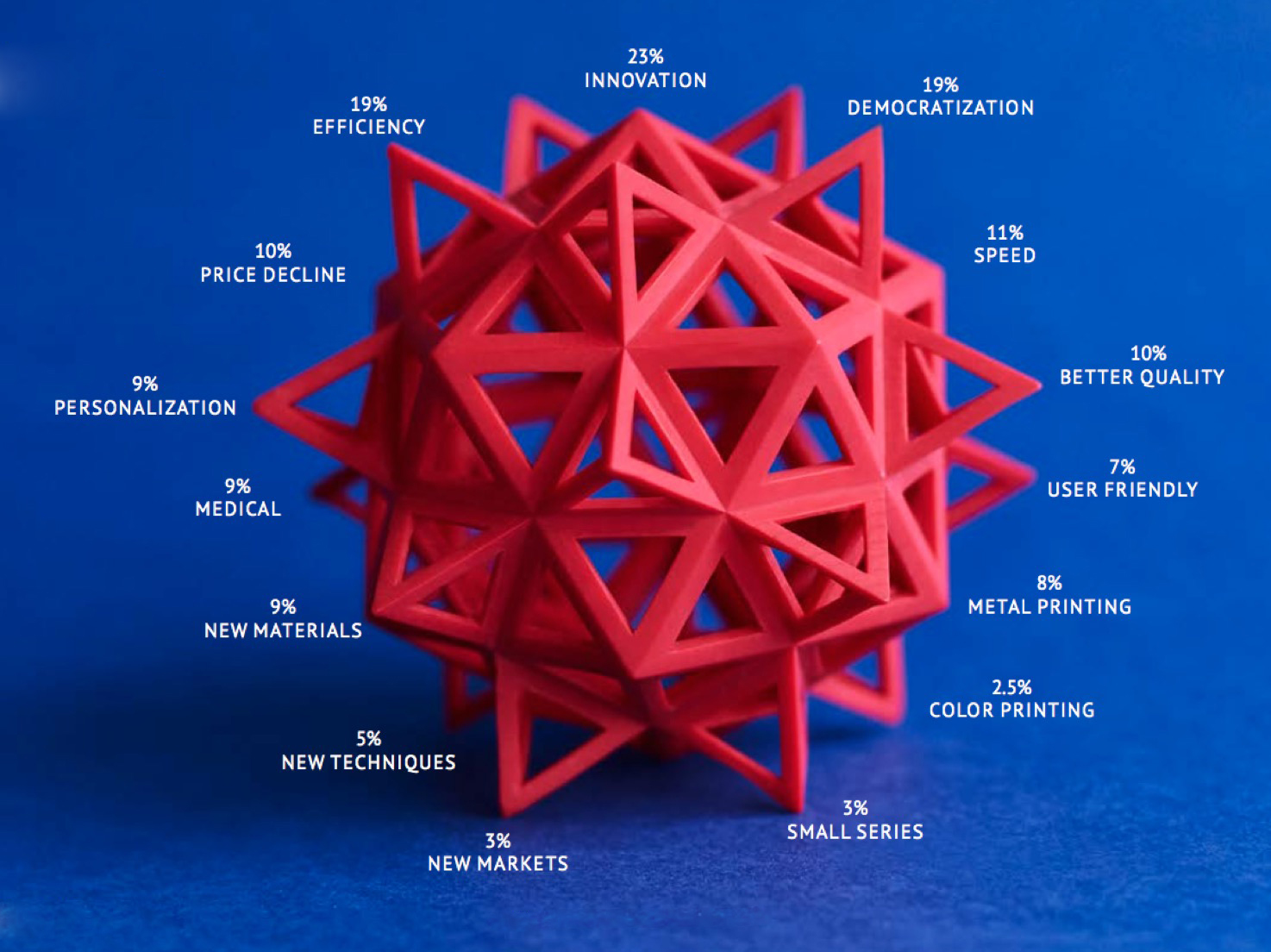

The respondents, as I do, believe the major trend in the space is the development of new 3D printing processes and materials, of which we’ve seen quite a few this past year.

Half of Sculpteo’s users mark themselves as “power users”, with most of them being professionally employed to work with 3D printing. The number of hobbyists is less, and likely to decline as industry catches on to the benefits of 3D printing. It seems that Sculpteo is attracting a loyal set of very serious clients involved in 3D printing.

But what are they doing? It turns out the professional users are primarily “accelerating product development”, or 59%. They’re printing prototypes. This is an excellent use case for 3D printing, and those that don’t do a sufficient number of prototypes to justify their own 3D printing equipment must use a service like Sculpteo. Interestingly, most of the power users (76%) say they’re working in a company that’s in “good health”. This suggests that 3D printing is being used by forward-looking, well-managed companies.

These clients are spending a great deal more on 3D printing. In 2015, the average 3D print budget per client was USD$3,736, while in 2016, it jumps 64% to USD$6,132! More 3D printing is apparently good for clients as well as Sculpteo.

That said, the most important concern of the clients is the cost of materials. This could be said for practically anyone in the 3D printing space these days.

There’s an awful lot more in the survey that I won’t get into, but if you’re interested, please journey to the Sculpteo site to get the full details.

Via Sculpteo