An extruder concept proposed by Reddit contributor lxo96 poses some interesting questions.

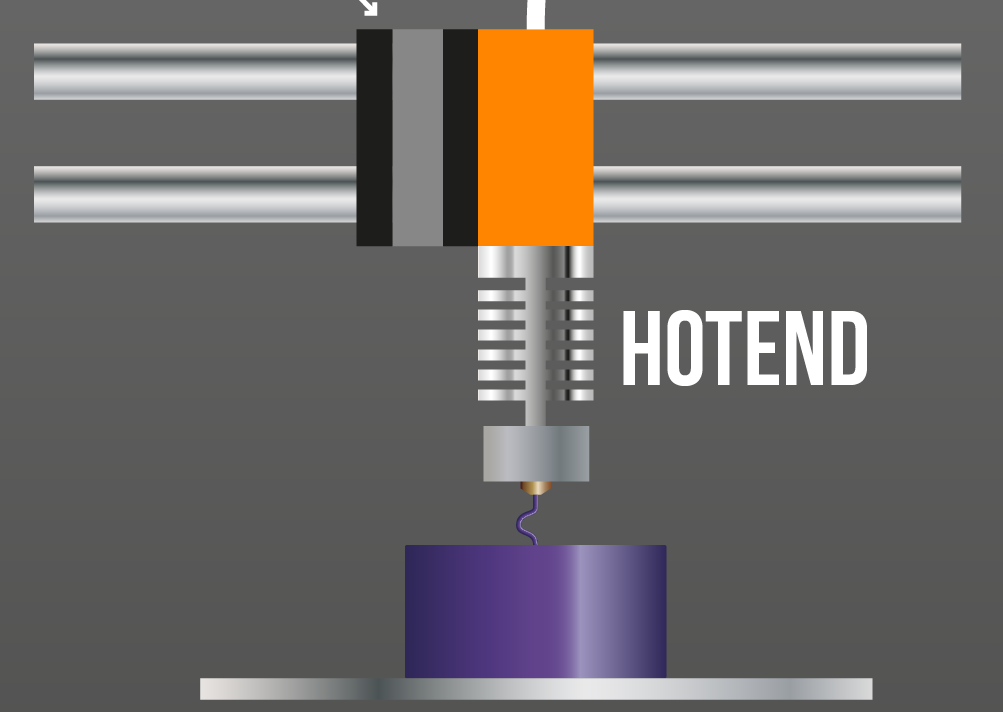

Typical plastic extrusion desktop 3D printers use either a “direct” or “bowden” style extruder. We explained the difference here, but the basic concept is that the “direct” extruder will pull the filament and immediately push it into the hot end, while the “Bowden” approach involves pushing the filament through a long tube towards the hot end.

The advantage of the Bowden approach is that the moving hot end is freed from a lot of weight as the extruder motor need not be moved with the hot end. This potentially makes the printer movements more accurate and faster, as there is less momentum to overcome during a trajectory change.

Some advantages of a direct extruder are the ability to print more flexible filaments, and a much easier way to accomplish retraction during travel movements.

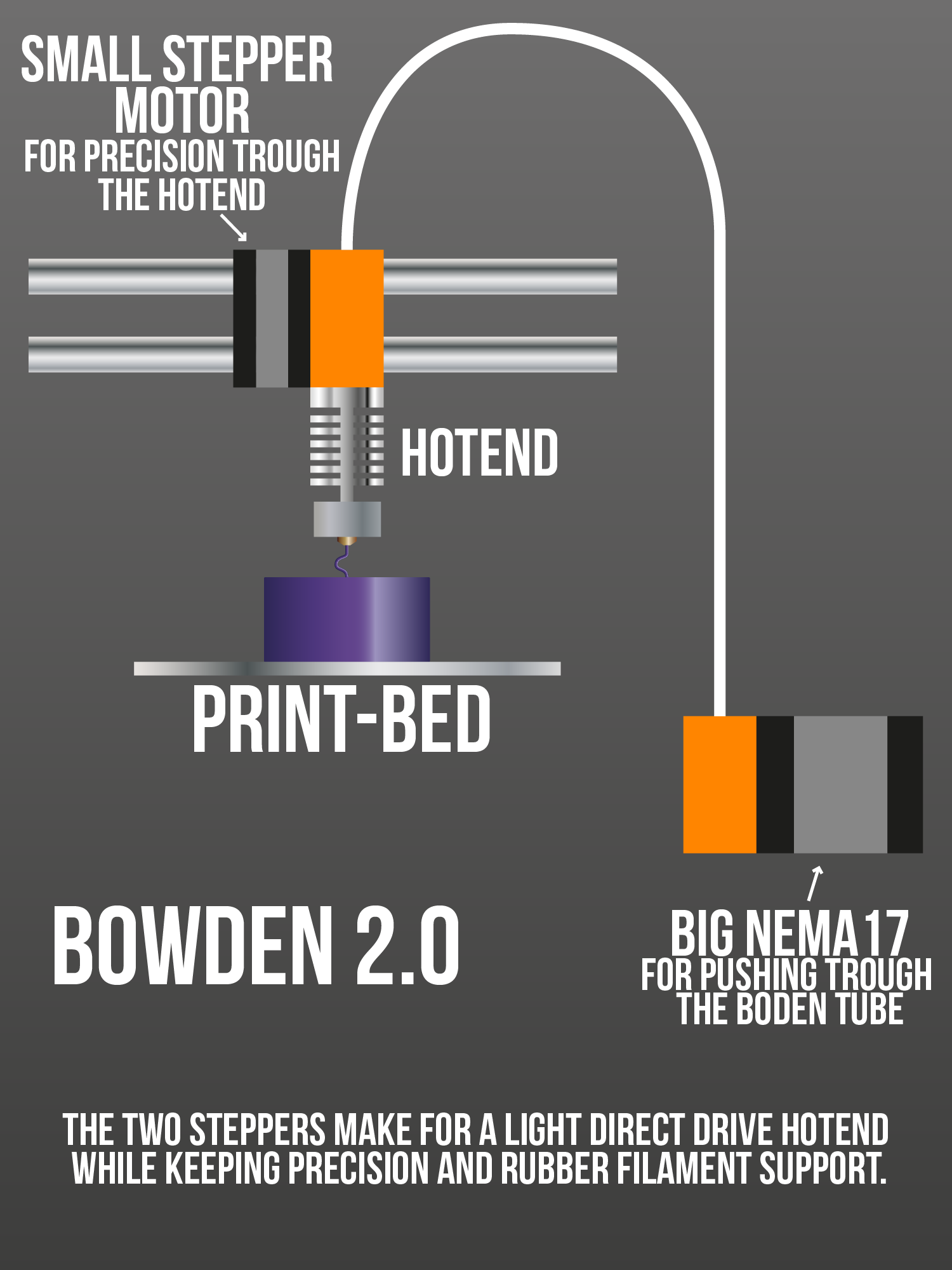

But lxo96 proposes a dual-motor system, shown here. It’s basically both systems combined, and theoretically offers the advantages of each, as the “direct” motor requirement would be far smaller, leading to a low weight solution.

However, as the discussion in the Reddit thread continues, there are a bunch of challenges. While the advantages are present, new concerns are introduced.

One major issue is the synchronization of the two motors. While they may be identical motors running at supposedly the same speed, are they really? What happens if the filament inevitably slips on one motor or the other? What happens if the filament slips gradually on one motor repeatedly over time?

How would retraction work? Filament slippage during retraction is a big issue, particularly if the model demands repeated retractions in a short period. The two motors would have to have some mechanism for auto synchronization, at least for the duration of longer prints.

Broken filament would generate some interesting scenarios, too. It’s possible such a configuration might be able to recover from broken filament to some degree, but that would require some work.

This dual motor approach is being done experimentally by several folks with varying degrees of success. It’s also standard equipment on Stratasys industrial 3D printers where there are motors near the filament cartridges and also near the hot end. Those machines are extremely reliable, so these are likely solvable problems.

Via Reddit