The RooBee One is a relatively easy to build completely open source high resolution resin-based 3D printer.

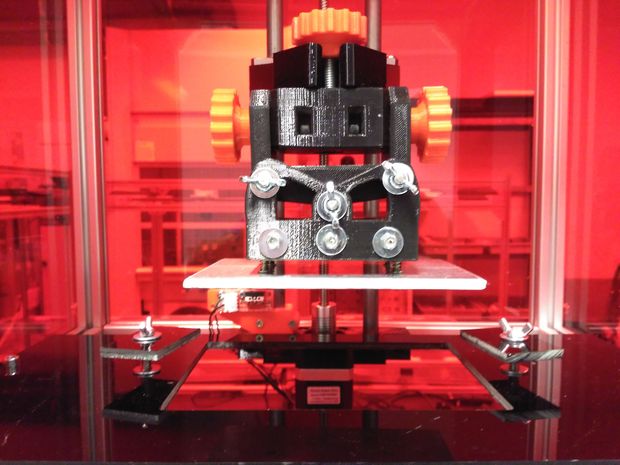

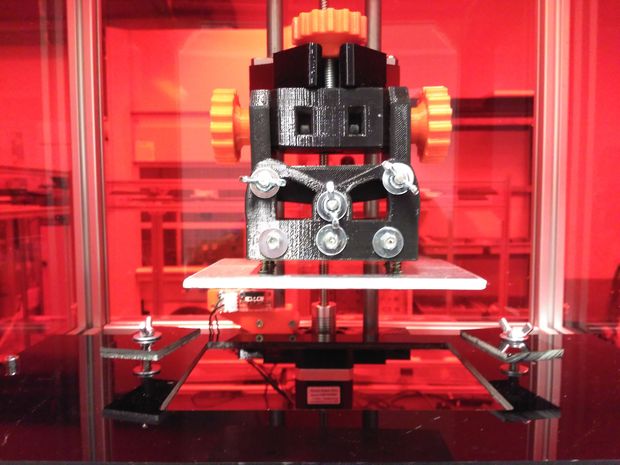

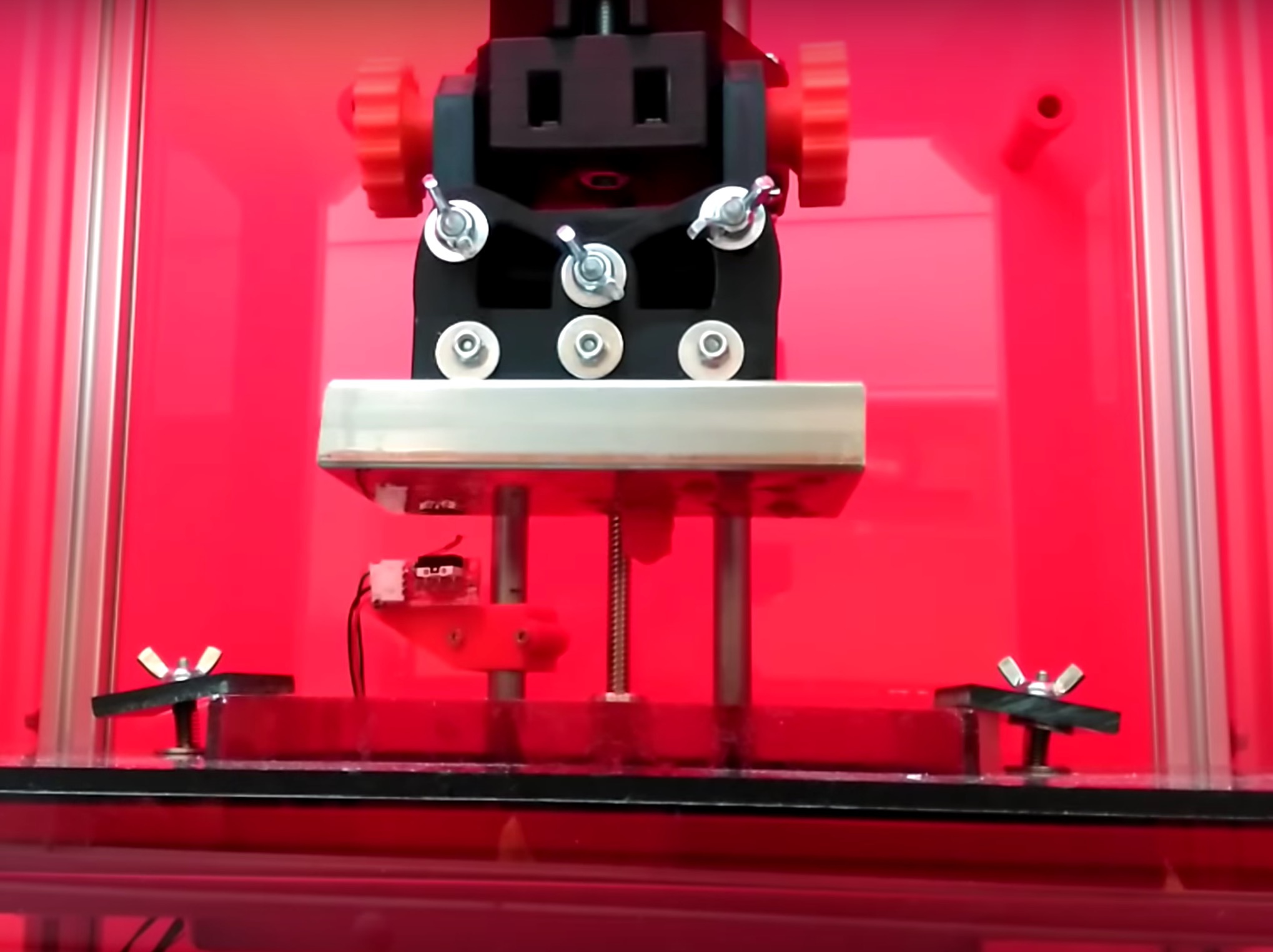

Developed by Aldric Negrier of RepRapAlgarve, the RooBee One uses the familiar DLP projection style of photopolymer 3D printing: a projector focuses light pixels on the bottom of a transparent resin tank, where solidification occurs. Layers are produced by gradually raising the platform.

Such a system is somewhat easier to construct than a plastic extrusion 3D printer simply because there are far fewer motion elements required: the resin printer requires only a working Z-axis; X and Y dimensions are automatically handled by the DLP projector, which illuminates an entire layer simultaneously.

Construction is shown in this video:

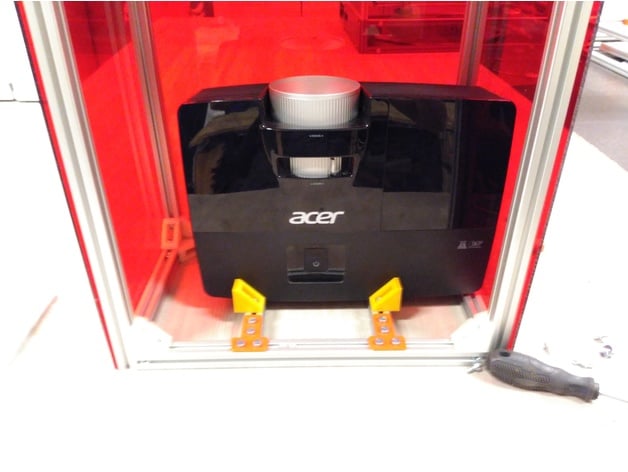

A key component of the project is a suitable DLP projector, shown here. The project would obviously be a lot less expensive if you happen to already have an appropriate ACER model handy.

The build volume of the RooBee One is slightly adjustable by adjusting the focus of the DLP projector. It can range between 80 x 60 x 200mm to 150 x 105 x 200mm. In other words, the DLP projection area is as small as 80 x 60mm or 150 x 105mm, creating different density of pixels and thus affecting both size and resolution of the printed object.

Finishing 3D printed objects does require some post processing, as shown here. Printed objects must be cured with UV light and washed in alcohol. The project doesn’t provide a sophisticated means of accomplishing this, so you’ll have to do something basic like the above.

Two concerns regarding this project you should be aware of. First, the technique will require replacement resin tanks, as the solidification process will gradually erode the bottom surface to such a point where light doesn’t pass through properly.

Secondly, resins can be toxic and the RooBee design doesn’t account for that, but does recommend ensuring appropriate ventilation be present.

Finally, why call this machine the “RooBee”? It’s a play on “ruby”, which happens to be the color of the transparent cover.

If you’re interested in exploring the benefits of resin-based 3D printing at low cost, this might be a project for you.

Via Instructables, RepRapAlgarve and Thingiverse