In a world of exploding smartphones, fictional augmented reality (AR) glasses and government spying, one might wonder whether or not new technology really advances the human predicament or if it just allows a few executives to score some extra dough here and there.

Occasionally, however, a new technology will come along and contribute dramatically to the quality of life for us humans.

This year, 3D Systems opened the doors to a brand new facility just outside of Denver, Colo. and, from a visit to the site, it became apparent that 3D printing, when used for medical purposes, really falls into that latter category. At the new Healthcare Technology Center, 3D Systems is actually doing whatever it can to improve life on Earth.

3D Printing in Medicine

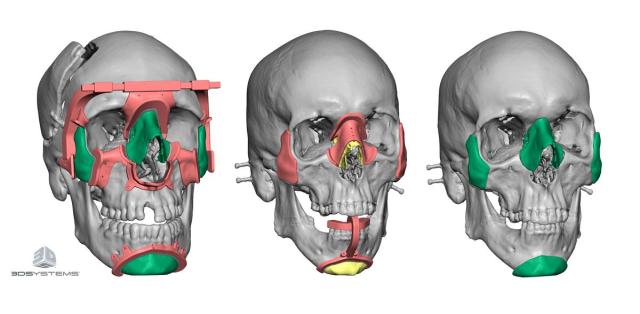

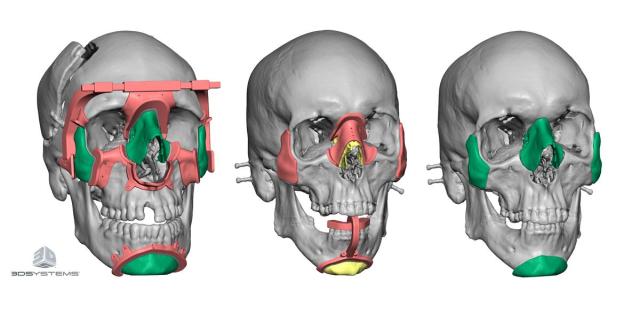

According to Gartner, healthcare is the industry first primed to be disrupted by the current evolution of 3D printing technology. This is because, at the technology’s current state, it’s already able to advance medicine greatly. By transforming a patient’s CT scan into a 3D model, it’s possible to diagnose an illness, rehearse a surgery, create surgical guides or even 3D print patient-specific implants.

These things are already happening and are already changing the lives of people worldwide. At the Healthcare Technology Center, the team has been performing these activities for over 15 years, resulting in a highly trained staff that works closely with doctors and surgeons to improve the lives of patients.

Prior to its acquisition in 2014, the Colorado group was known as Medical Modeling. Along with Simbionix and LayerWise, which were also bought by 3D Systems in 2014, it represents a key component of the 3D printing firm’s Healthcare Division. Now, the site performs engineering, consultation and additive manufacturing as it relates to patient-specific medicine.

From DICOM to Print

Creating a patient-specific print usually starts with Digital Imaging and Communication in Medicine (DICOM) data, a patient’s CT scan as represented by some 200 individual grayscale slices. Experts at 3D Systems compile this data and filter out the information required to make a 3D model. Selecting the light areas on every layer, for instance, it’s possible to isolate just the bone within a scan and create a 3D model of a patient’s skull. Once the model is cleaned up and refined, this can be exported as a standard, 3D printable STL file for further work.

3D Systems is aiming to partially automate and streamline this process with its own proprietary software, DICOM to Print. Though still in development, the tool will make it possible for medical professionals to create 3D printable models from CT data without relying as heavily on trained engineers, such as those at the Healthcare Technology Center.

As a 3D model alone, this can already be an invaluable tool for doctors. 3D printed in full color gypsum with 3D Systems’ ColorJet Printing, the model can make for the perfect teaching aid to educate patients about a given health condition. 3D printed in translucent and pink plastic with stereolithography (SLA), the object can highlight that condition more clearly. Or, when printed in multiple materials with MultiJet Printing, it’s possible to even simulate the actual tissue of an organ to rehearse a surgery.

However, with this 3D model, 3D Systems can also help surgeons worldwide to create medical devices and even plan procedures. For this, the file heads to the facility’s engineers, who actually work hand in hand with doctors to execute treatment plans—a service that 3D Systems has branded as Virtual Surgical Planning (VSP).

At the site, it was possible to overhear a biomedical engineer teleconference with a surgeon. In a demonstration case presented to us, one engineer explained that he could share his or her screen with the doctor in order to design and place the proper surgical guides for resectioning a skull to alleviate pressure caused by congenital cranial abnormalities. As the 3D Systems employee moved a guide on the screen, a doctor on the other end of the phone might ask for it to be rotated or moved. This process would continue until the device was complete.

Read more at ENGINEERING.com