Austria-based Hage markets a pair of powerful professional 3D printers with some unique features.

The 35-year old company began as a contract manufacturer, but over the years gradually began introducing their own line of manufacturing equipment. Having developed many large-scale CNC machines, the company introduced a plastic extrusion 3D printer in 2014, and today the company offers two models.

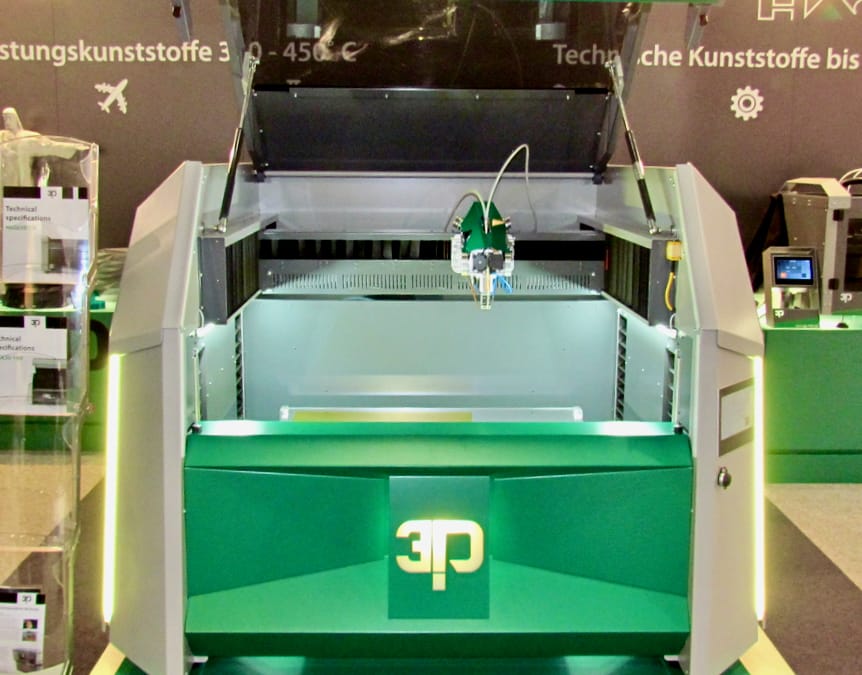

The HAGE3D 72L is a large unit, but the slightly smaller of the two Hage machines. In it’s very generous 600 x 400 x 280mm build volume you will be able to 3D print a variety of engineering materials including ASA, M-ABS, PET-G and PMMA.

The larger HAGE3D 140L has a 700 x 500 x 400mm build volume, and can print in ASA, M-ABS, PET-G, PMMA, PC and PPSU/PEEK. I’m told even ULTEM is possible as well. Both machines are able to make use of open materials in their heated build chamber.

Of course, the machines are built with precision-made parts, which is not unique to Hage. But what I find interesting are several features included in the machines that aren’t typically found in other equipment.

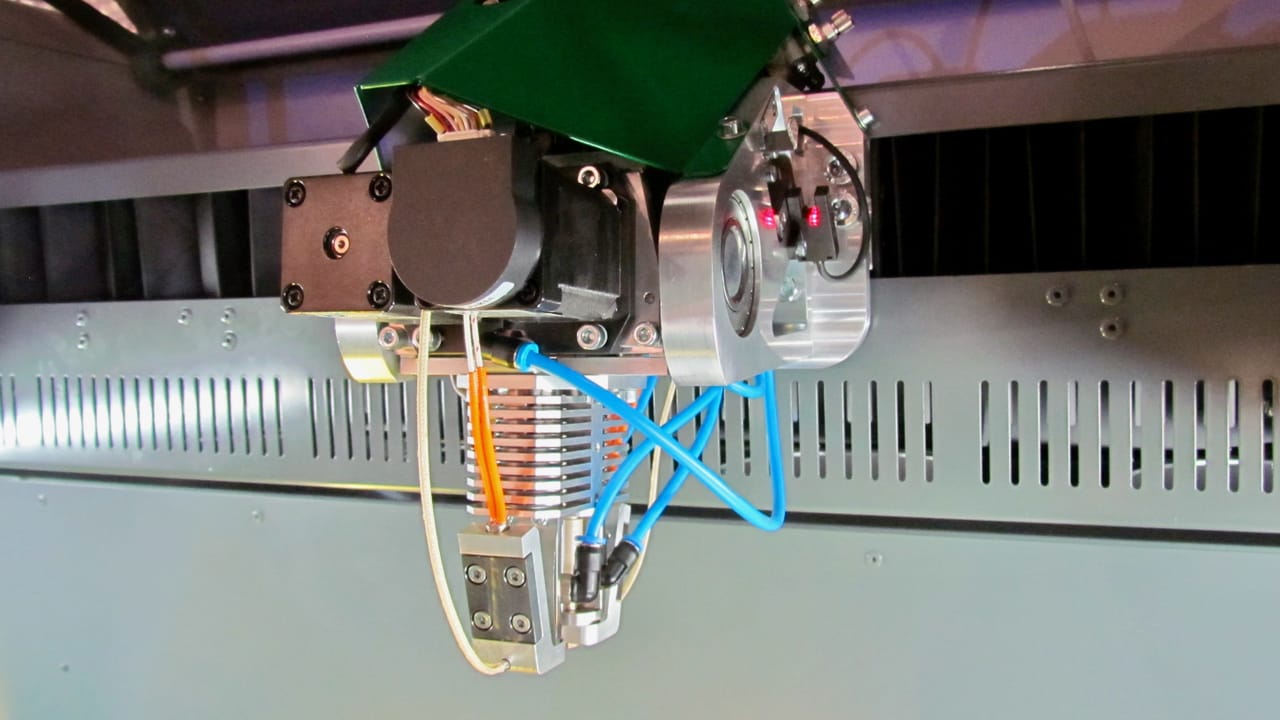

The extruder is quite unique in that it makes use of compressed air for cooling, which they describe as “instant”. This feature is critically important as the high temperatures used in this machine are avoided in the “cold” portion of the extruder.

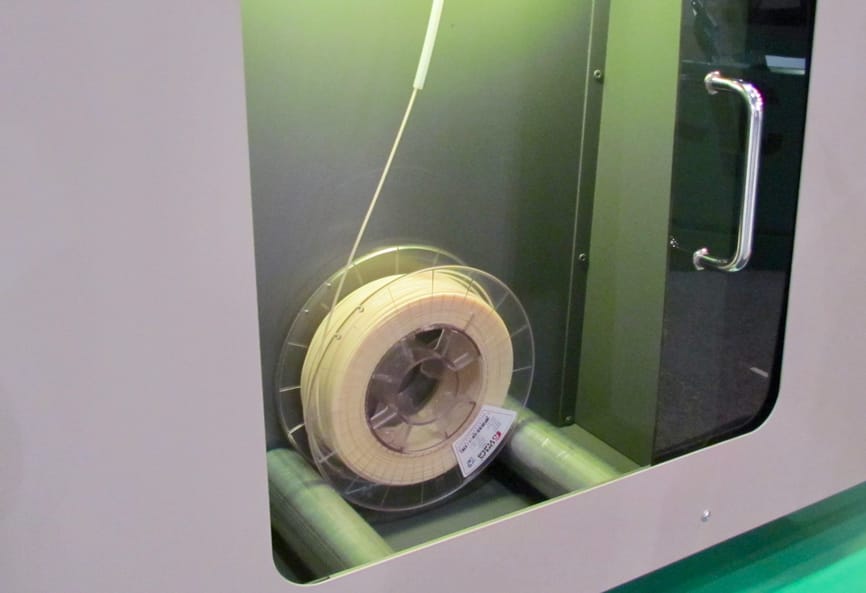

The spooling system, shown here, is able to accommodate spools up to 4kg. I particularly like the simple design of this system, which can instantly hold almost any spool format or dimension.

The two units also include a security system in which only authorized users are permitted to change machine parameters, such as calibration. This makes the machines much more practical in shared environments where there may be many people with different machine skill levels on the loose.

And that’s likely where this machine is intended for use: a workshop where it will run for great lengths of time. Hage explained that the machines are rated for 5,000 hours per year, or about 19 hours a day, Monday through Friday. That’s more or less continuous business operation.

Pricing of these units is reasonable for this type of machine, and in fact is less than the leading competitor. The 72L is priced at €25K (USD$27K) and the 140L is €70K (USD$74K).

Via Hage