I’m reading a piece by VoxelJet explaining how they’re working with a client, but it occurred to me there is a tradeoff to consider.

VoxelJet is a specialized 3D printer manufacturer, whose devices produce very large industrial molds for casting metal. In fact, their VX4000 unit has a monstrous build volume of 4 x 2 x 1

The project they’re working on is actually quite interesting: it’s making components for a Dutch university who is building a HyperLoop, Elon Musk’s fantastic high speed inter-city transportation system. Delft University of Technology is involved in a contest with other institutions to eventually produce a working HyperLoop system.

To do so, they required a number of very complex, highly-precise parts that would be ridiculously complicated if built in conventional ways. They turned to a commercial prototype maker, RP2, who worked with VoxelJet to produce the parts.

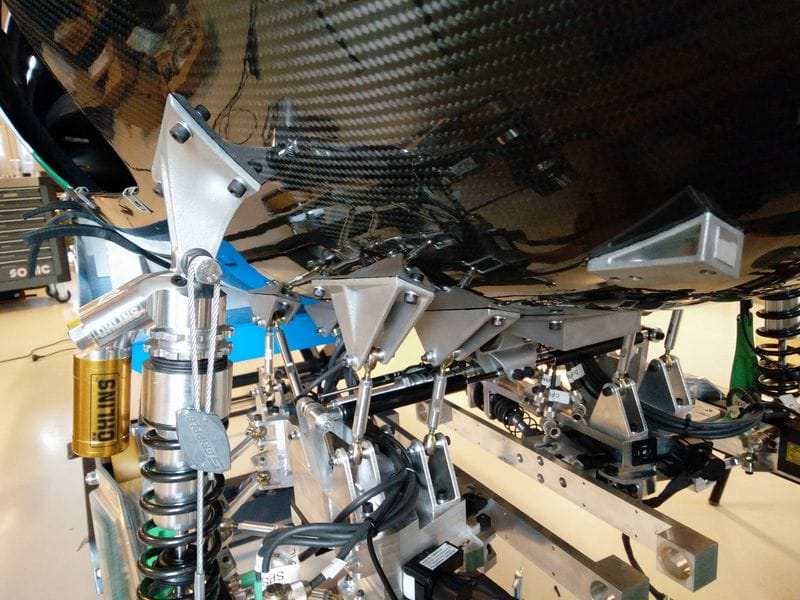

The parts, as you can see here, are indeed complicated. Making this with a normal, reusable mold (one that splits in half to remove the object) would require redesign of the object’s shape to account for all the overhangs. More than likely you’d have to split it into multiple parts and include bolt holes, lugs and more to attach them to each other, add to the part weight.

VoxelJet 3D printed the object (shown here) in PMMA, an excellent casting material, to precise specifications.

The part and other simpler parts were joined together with a wax “tree” through which metal would flow for casting, shown here. The process involves pouring liquid ceramic around this structure, which hardens. After hardening, the item is fired in a furnace to burn out the wax and PMMA, which evidently burns out with little to no ash residue. This leaves a hollow ceramic structure in the precise shape of the desired objects. Liquid aluminum (in this case) was poured in an cooled to solidify.

To remove the object, the ceramic mold must be broken apart, as there would be no other way to release the “overhangy” object. After some post casting heat treatment and polishing up, the aluminum parts are ready to go.

But here is the tradeoff I mentioned: the ceramic mold in this case must be destroyed each time parts are cast. If you require a large number of the parts, then you’re going to have to 3D print a positive cast, surround with ceramic and burn out each for each and every unit.

The ceramic part isn’t that expensive, but the 3D printing can be expensive, particularly for larger objects. This is effectively adding cost to the price per unit produced.

The alternative is to utilize a reusable mold – but as I said earlier, that would require redesign of the object to account for the reusability. It would certainly lower the cost of each unit produced, at least as far as the casting process is concerned.

But it might ADD cost for assembly, spare parts inventory, reliability (more pieces increases the odds of something bad happening) and more. It’s also possible the weight of the object might be too heavy for the application if split into multiple parts.

So what is the right answer? I think it depends on the specifics of the situation, and would require a decent analysis of all factors including both production of the part(s) and the use, management and maintenance of them after production.

Each approach has advantages and disadvantages; 3D printing is not necessarily the right answer in all cases.

But in this case, it apparently was.

Via VoxelJet