I listened to a talk by a GE representative who explained why they see so much benefit in 3D printing, and it’s quite startling.

In the talk, they explained how 3D metal printing technology could produce parts not achievable by traditional manufacturing methods. These parts would be used to produce equipment with far fewer components because the components could be 3D printed with much greater complexity.

This we’ve heard before. But what I hadn’t heard before was the statistics of how much benefit this could actually accrue within a company using the technology.

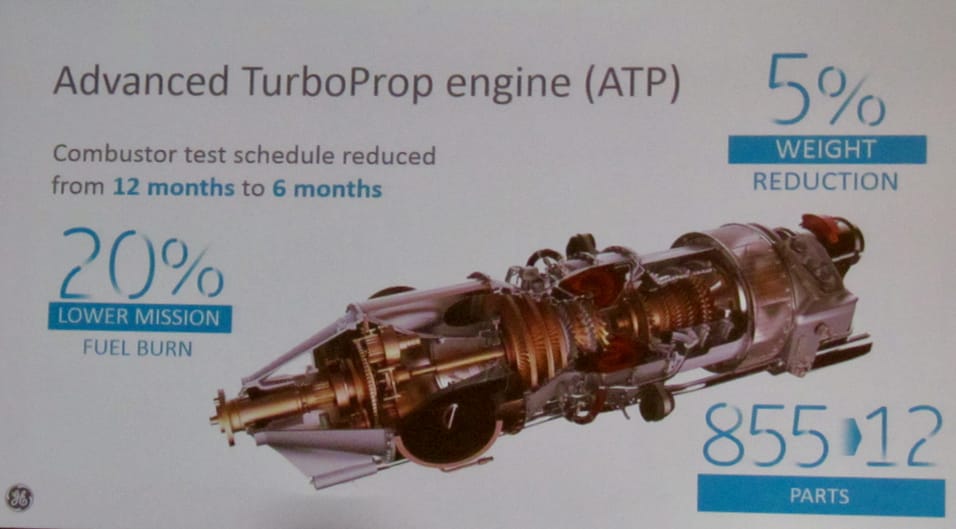

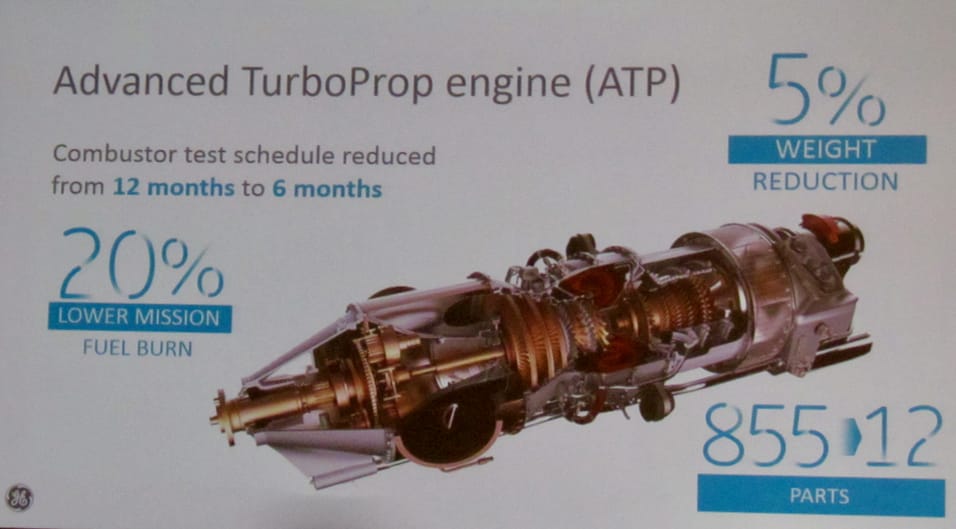

Apparently in the GE aerospace project in which they developed a new engine with significantly increased number of 3D printed metal parts, they observed multiple and significant cost savings:

- They were able to reduce the number of suppliers from fifty to ONE

- They were able to reduce the number of subsystems from 40 to ONE

- They were able to reduce the number of parts from 855 to only 12

These are very significant, and not just in terms of manufacturing effort. The number of suppliers, 50, for example, suggests GE would have had to have a considerable team of experts present to simply administer the corporate relationships. This would have included legal, negotiating, quality control and administrative resources. All of those are human labor resources that no doubt were expensive.

Subtract that from the total, along with the 39 fewer part making activities and you will certainly get huge savings. As well, the resulting systems would be lighter and higher performing on aircraft as they could be designed as such.

The relatively high cost of 3D printing in metal likely is still offset by these considerable savings, making a venture into 3D metal printing quite profitable.

This gives one an understanding of why GE is barreling ahead full speed on 3D metal printing in their business. They’ve scooped up not one, but two 3D metal printer manufacturers recently, as well as integrating the technology deeper into their operations.

And while GE seems far ahead on the adoption curve, I am beginning to wonder about their competitors, who may be left behind. They will certain find out when their products turn up to be slower, heavier and more expensive than GE’s.