Researchers at Binghamton University have explored ways to theoretically increase the speed of filament-based 3D printing systems.

While there have been countless business experiments with different types of extrusion systems, it seems that today’s desktop 3D printers using filament extrusion have settled on a particular combination of mechanical and thermal elements to produce machines that print successfully between 30-150mm per second.

There are a few machines that boast of higher speeds, largely through the use of powerful real-time motion control systems. http://www.fabbaloo.com/blog/2015/5/21/create-it-real-supercharges-the-hotrod-henry

However, how can one increase the speed of printing theoretically?

The researchers realized that the effective print speeds are a result of combining several elements:

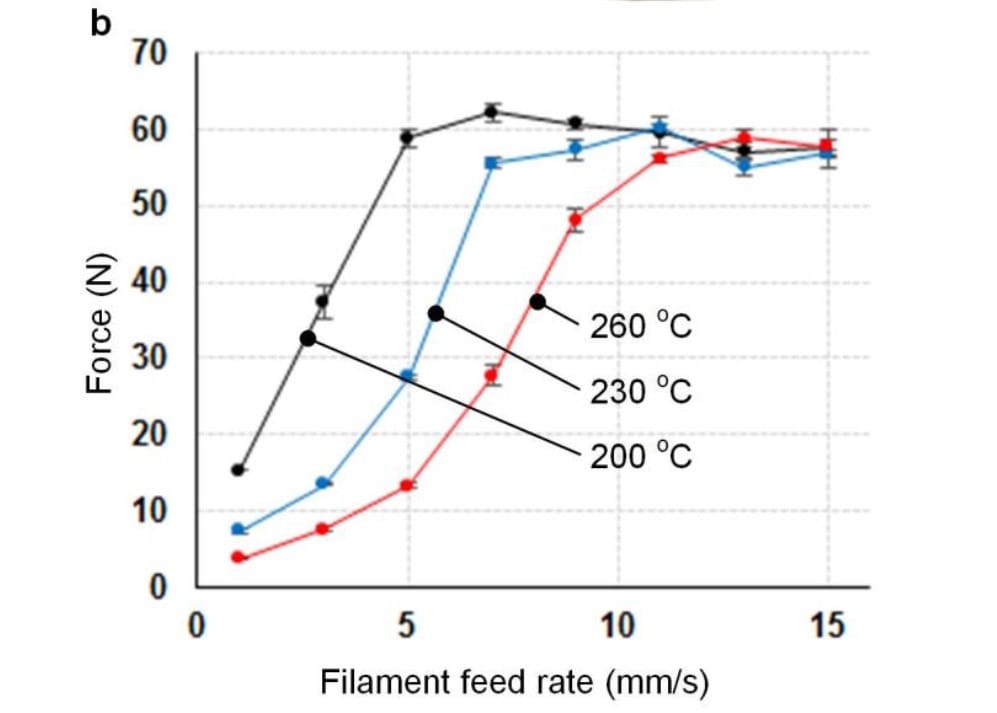

The filament feed: The system responsible for delivering filament to the hot end, usually composed of a motor and grabbing mechanism (a pinch wheel) to push the filament.

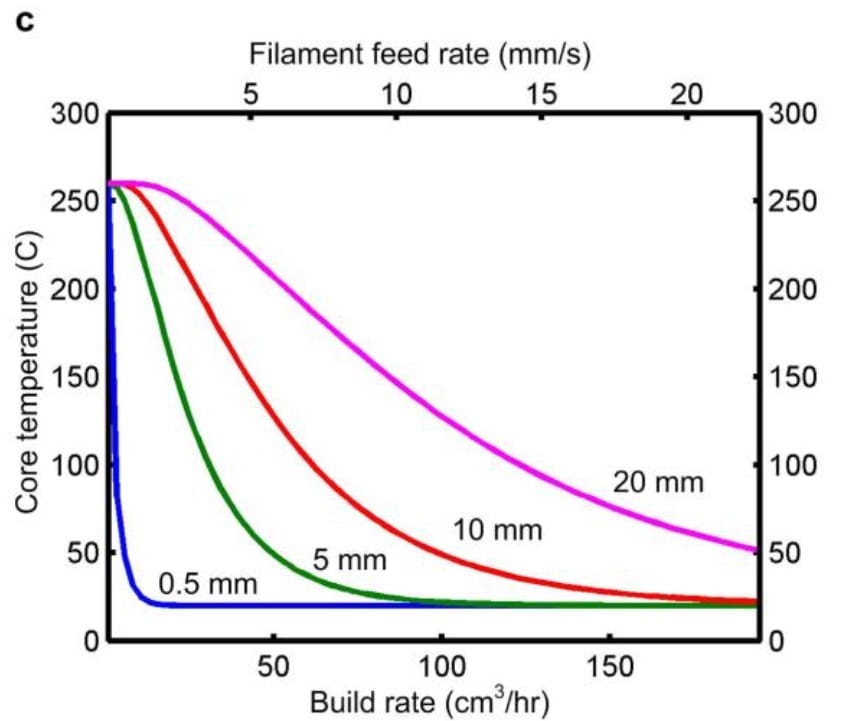

The liquifier and nozzle: Where the plastic filament is heated very quickly to the appropriate temperature for extrusion.

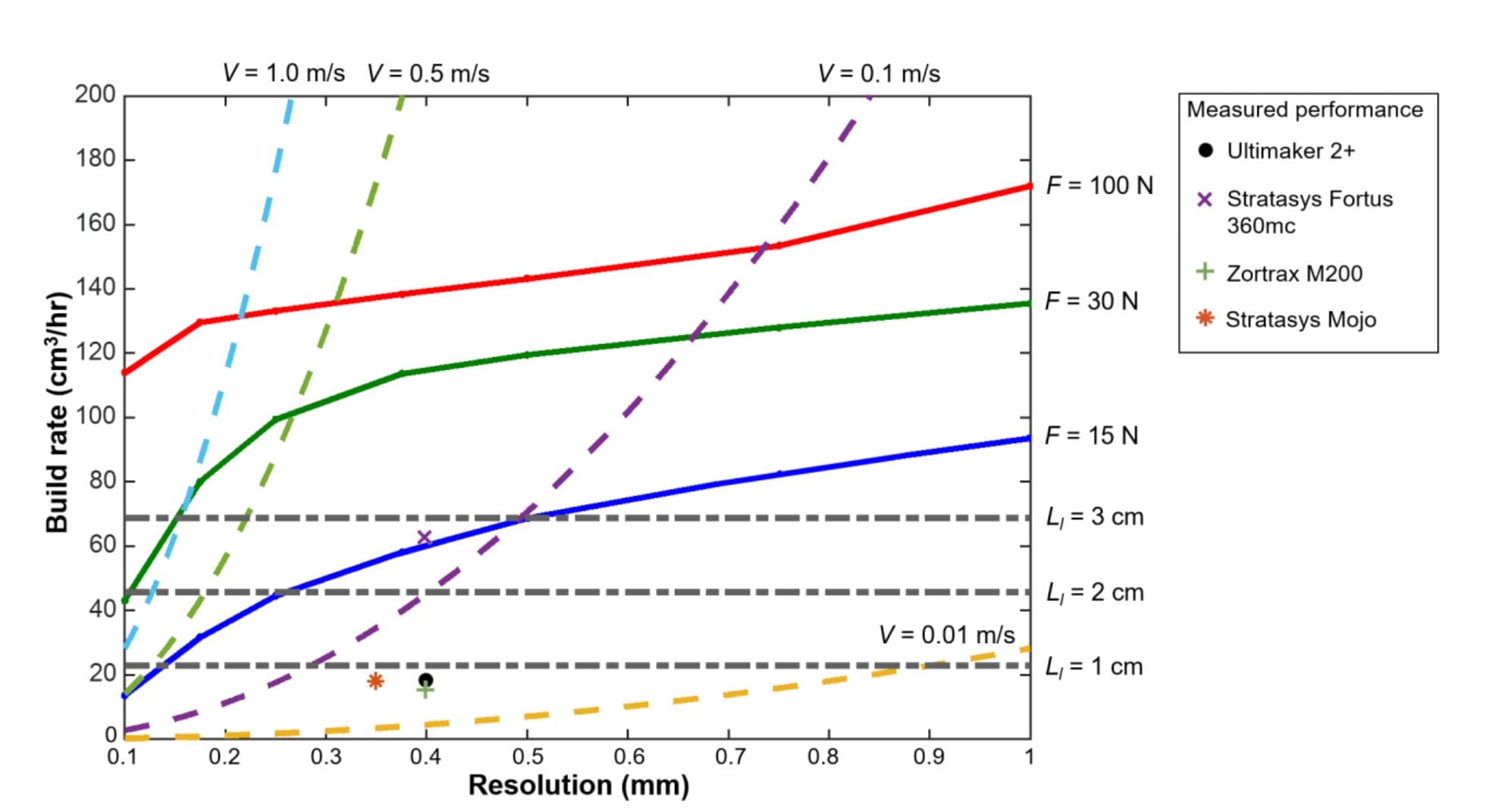

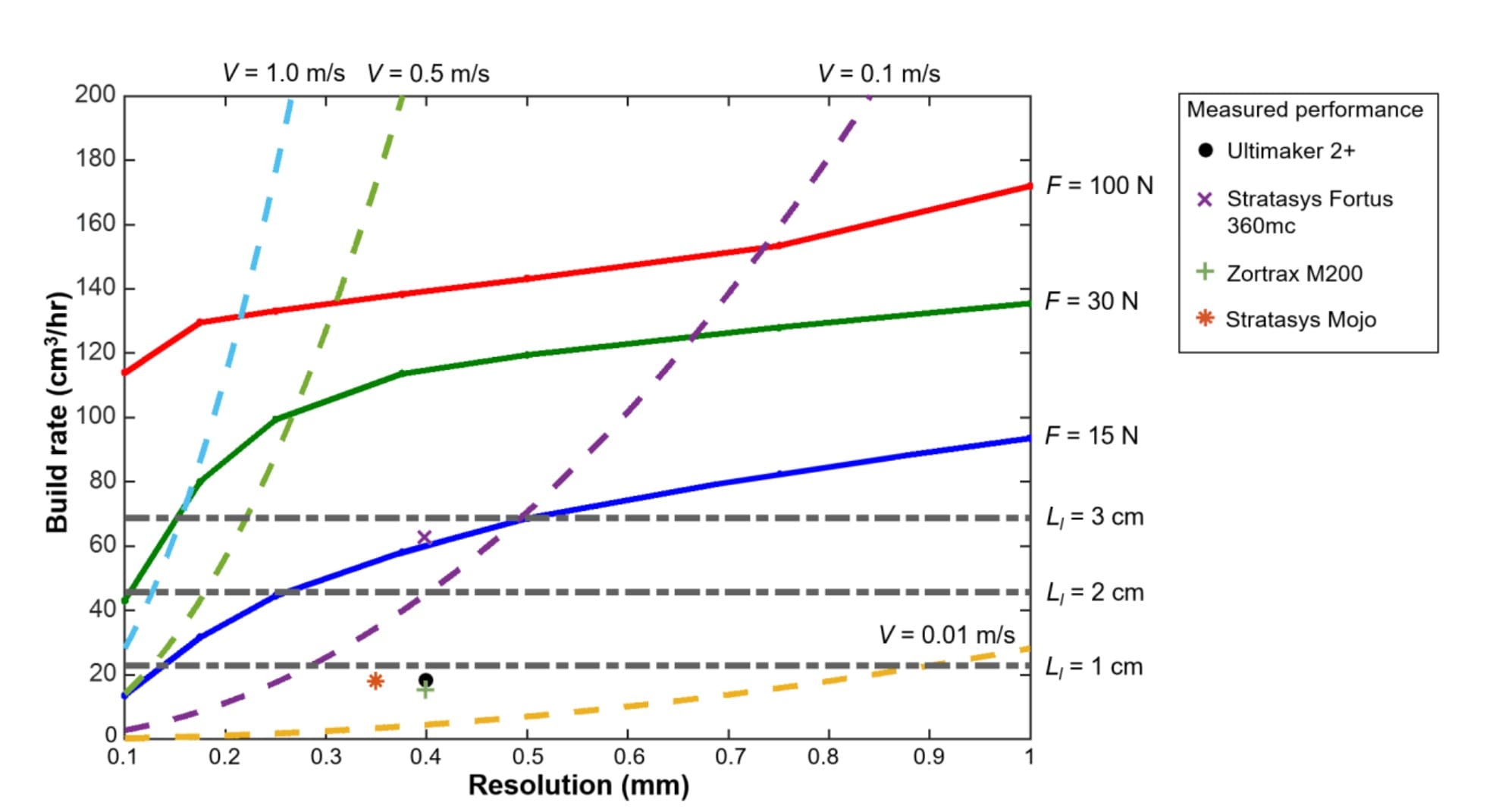

The motion system: Where the nozzle is moved quickly about on the build plane to effect deposition of the polymer material.

These three factors must be in balance for successful 3D printing, but even so there are seemingly physical limits to what can happen.

For example, if the plastic is rammed through the liquifier at too high a speed, it may not have sufficient time to soften. If the motion system moves faster than the material emerges from the nozzle, you’ll have a skimpy print.

They determined that filament should theoretically fail when pushed with the force of 53.2N. They then attempted to run polymer filament through a standard hot end at various temperatures and observed when the shear force exceeded this value, in other words when the filament stripped. They also developed a mathematical model of typical 3D printer motion systems. They observed a maximum theoretical speed of 394mm/second, but realize that it can never be achieved for a variety of reasons.

Their overall model of how this works indicates that the maximum theoretical speed of a 3D printer is based on the most restrictive component. Their work also shows that the most effective heating system is one that has a long length; this makes sense as the plastic would be exposed to the heat for a longer time period, allowing more time for softening. They say this approach results in the least requirement for extruder force.

There’s plenty of engineering details in this paper, and it should be examined by anyone considering building a 3D printer: there are ways to optimize the design for maximum speed.