Belgian company Thrinno has announced a rather interesting new service that could be quite profitable for some 3D print operations.

Thrinno has previously been known for providing a sophisticated 3D print quotation service, something that might be of interest to those operating a bank of 3D printers for hire. The job of providing accurate quotes can be a complex matter, thus the need for such a service.

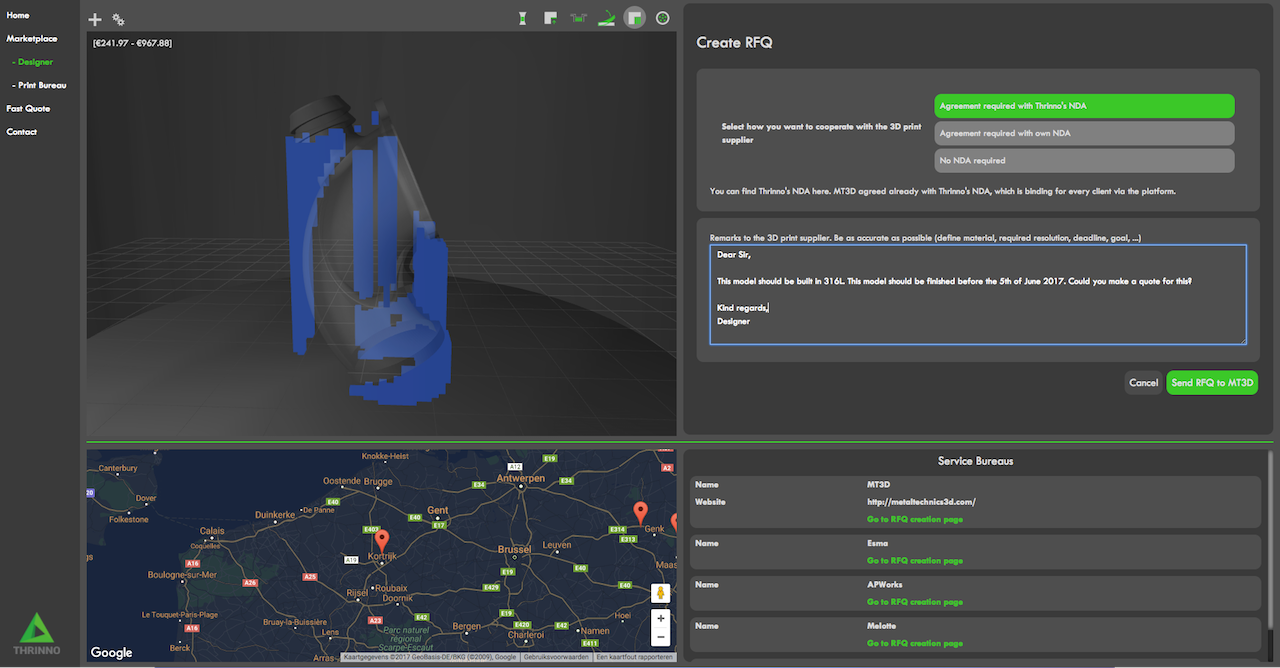

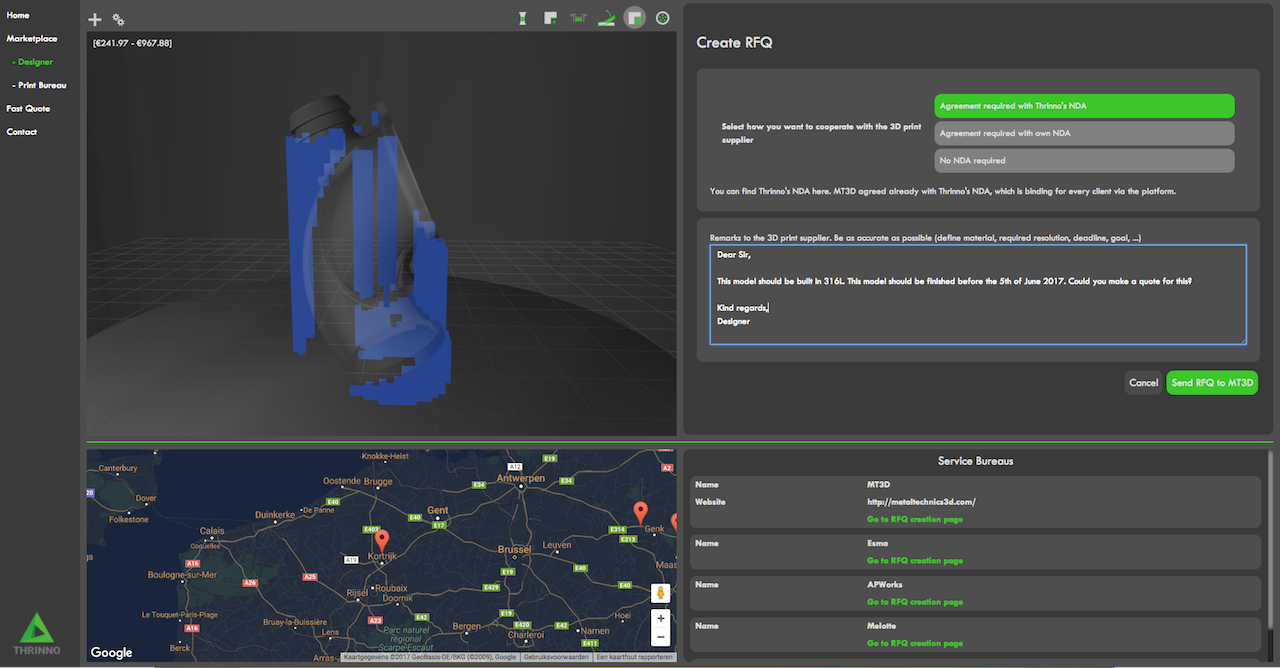

However, it seems there are quite a few options available today if you’re in the market for a 3D print quotation service. Thus it seems that market forces have encouraged Thrinno to try something new. Their new offering is the Thrinno Marketplace, a 3D print service with a difference.

Typical 3D print services receive requests and they must be scheduled for production on the recipient’s equipment. In the interests of efficiency typical services will batch together as many requests as possible into a single job run. This is done because much of the non-printing costs of a print job are done manually per job: loading material, preparing the equipment, unloading the prints, etc. By defraying those manual costs over more prints, greater efficiency is achieved.

But Thrinno’s new Marketplace 3D print service is different in that it has no 3D printers of its own, but instead relies on a network of associated 3D printers from other companies. The twist here is that the new Thrinno software enables these provider participants to leverage unused space in their already-occurring print jobs.

In other words, a participating company could make some extra cash by simply allowing a Thrinno Marketplace requestor to piggyback on their print jobs.

The system will operate in auction style, where those participating providers with excess build plate capacity can bid on incoming requests, maximizing the utilization of their presumably expensive production 3D printers.

I asked Thrinno’s Anthony Cloet how this is technically accomplished:

For the parts that can be scheduled in at ‘leftover build plate space’ we are in different phases of integration with different service partners… We are working on an optimal 2D nesting algorithm that perfectly nests in the part on the build plate while taking into account the dimensions of the existing parts. Our current software Thrinno Fast Quote already allows the user to specify the occupation rate of the build plate and takes into account height differences in oriented objects when allocating costs to components.

This is a very interesting concept and could result in lower costs for those requiring 3D prints.

I have to think that this concept is somewhat similar to the 3D Hubs concept, where a network of participants provide the equipment to produce the prints. However, it seems that Thrinno’s integration into build plate activities is deeper.

The Thrinno Marketplace will succeed only if providers decide to become participants. Cloet says:

All of the service bureaus we currently have had contact with agreed on us forwarding them customer inquiries via the platform to check availability of the machine. Nobody really says ‘no’ to qualified leads.

This sounds quite promising.

Via Thrinno