A surprise press release from Contour Crafting suggests the company is positioned to produce massive 3D building printers.

Contour Crafting was one of the first stories we covered almost ten years ago, when they proposed a concept for 3D printing entire buildings in concrete.

Since then, the company has been rather quiet. The man behind the venture, Dr. Behrokh Khoshnevis of USC, has had some press in the interim regarding ideas for 3D printing lunar material, but there seems to be little information – and perhaps progress from Contour Crafting itself.

Here is a short video explaining their concept, from 2006:

And another more recent video:

Until this month, when the company announced they’ve struck a deal to get things going. According to reports, Austria-based Doka Ventures has taken a 30% stake in Contour Crafting.

Wait, who is Doka Ventures? They are the innovation subsidiary of Austria’s Umdasch Group, a company specializing in “formwork solutions for cast-in-place concrete construction”. In other words, they produce highly challenging concrete structures, just the kind of thing that would be helped by a viable 3D concrete printer. They describe their subsidiary, Doka Ventures:

Doka Ventures deals with new technologies in construction. The company engages actively in models for optimization of the construction process in its entirety. By participating in or initiating research and development projects, through supporting technology start-ups and by acquiring companies that specialise in pioneering methods.

Again, this is a strong fit for Contour Crafting’s concept.

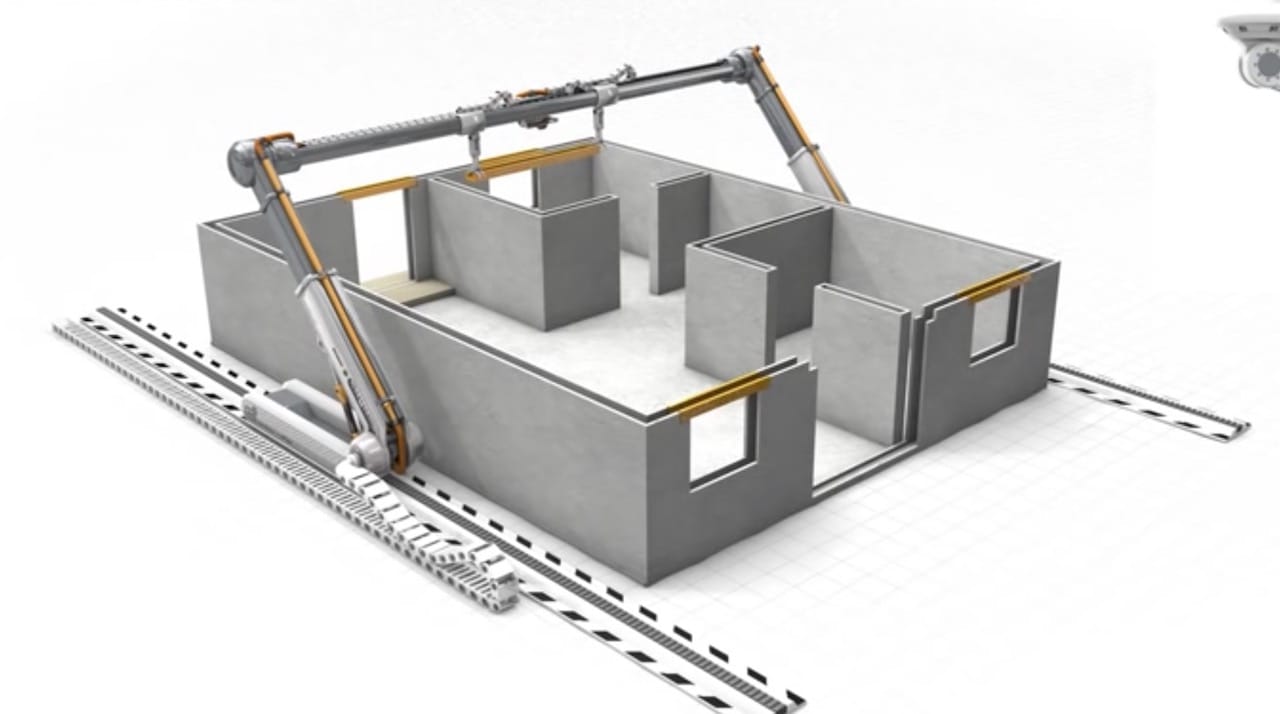

With the investment from Doka Ventures, Contour Crafting is establishing a 36,000sf manufacturing facility in Los Angeles where they will begin constructing 3D concrete printers similar to the concepts we’ve seen previously. Their target is to ship them in early 2018.

The idea behind the concept is to save money and time by extruding concrete shells for buildings in a far more automated way. Currently it can take weeks to produce a building shell using conventional techniques.

That automation is, in theory, easily accomplished with the Contour Crafting concept: simply deliver a 3D concrete printer to a building site, as the machine is said to weigh only 400kg and can easily be transported and assembled. Once fueled with concrete, it can run continuously to print the building shell, layer by layer.

However, note that this is only to print the building shell in concrete and certain other components, and not “3D print a usable building”. Operators will still need to bring in traditional plumbers, electricians, HVAC specialists, window framers, painters and other finishing skills to make the building inhabitable and functional.

One aspect of the Contour Crafting concept that’s different from other 3D building printer ideas is that it recognizes the need for components other than simply the concrete shell. The concept includes a robotic arm feature that can install pre-made insulation, door frames and several other basic components.

It’s not quite the whole building, but they are taking steps in that direction.

The best part is that it’s apparently for real and will ship in 2018.

Via Contour Crafting and Doka Ventures