I’m reading about the fascinating progress of Momentum Machines and wondering how their approach could apply to 3D printing.

If you’re not familiar with Momentum Machines, they are a California-based startup company on a mission to develop a fully automated food preparation robot.

Sounds pretty clinical, but in fact this is what this machine does: It prepares and cooks a complete and tasty hamburger from basic ingredients on command. There is no human involved in the operation, aside from loading tomatoes, meat and other raw materials into the machine, and the customer receiving the delicious burger at the other end.

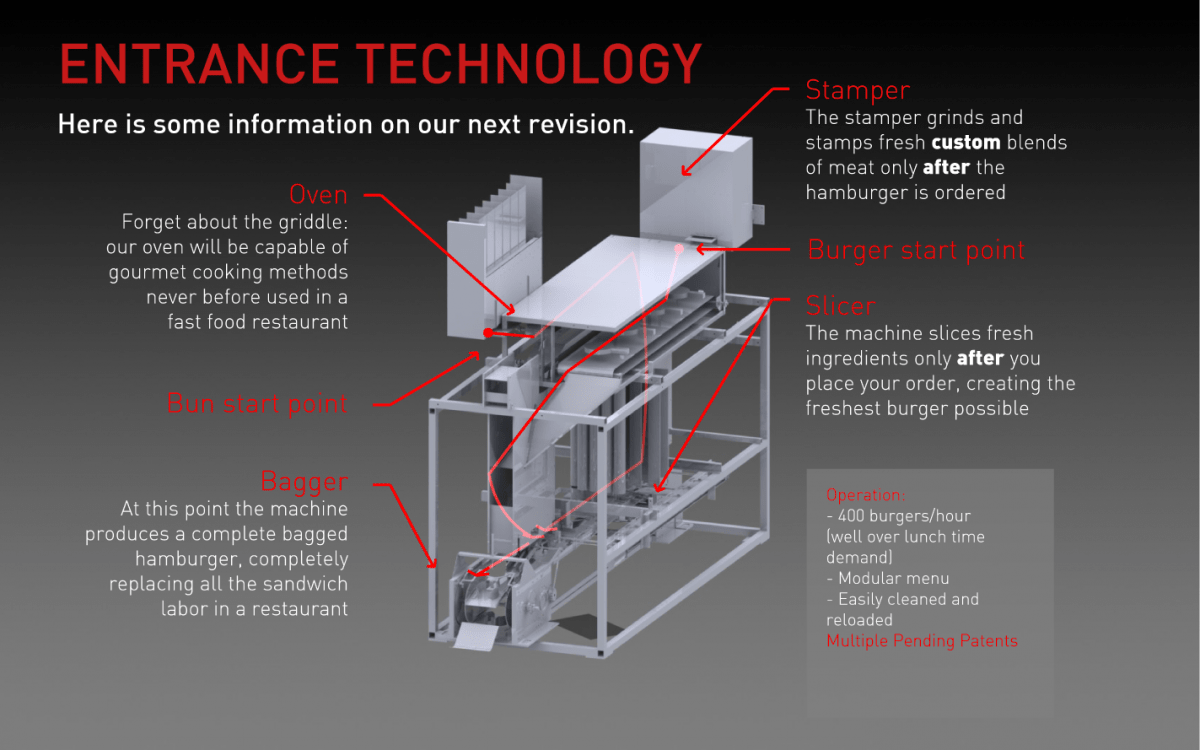

Here’s a schematic of how it works:

Their goal is not simply to reduce the human operator component, but to completely eliminate it.

It’s an incredible vision that more than likely will be deployed into fast food restaurants worldwide, with the company following on with other robotic automation systems for other food products and industries.

But what does this have to do with 3D printing?

A lot, I think. Today’s 3D printers are essentially like the grills in current restaurants. It’s the key technology in the process, but must be augmented by a large degrees of manual intervention before and afterwards.

3D prints must be manually removed from machines, have support structures removed somehow, surface smoothing applied, paint or plating, assembly of parts in some cases and even packaging.

The cost, time duration, reliability and quality of all that manual work may be considered a barrier to the adoption of 3D print technology by many industries.

What if the Momentum Machines philosophy was adopted by 3D printer manufacturers? What kinds of machines would we see? What types of processes would be included in the system? What kind of parts could emerge from such systems?

Certainly there are some signals from a few forward-thinking manufacturers today, as they attempt to simplify portions of the process, but no one, as far as I know, is attempting to automate the entire process.

But then, maybe someone is working on that and hasn’t launched yet.

Via Business Insider