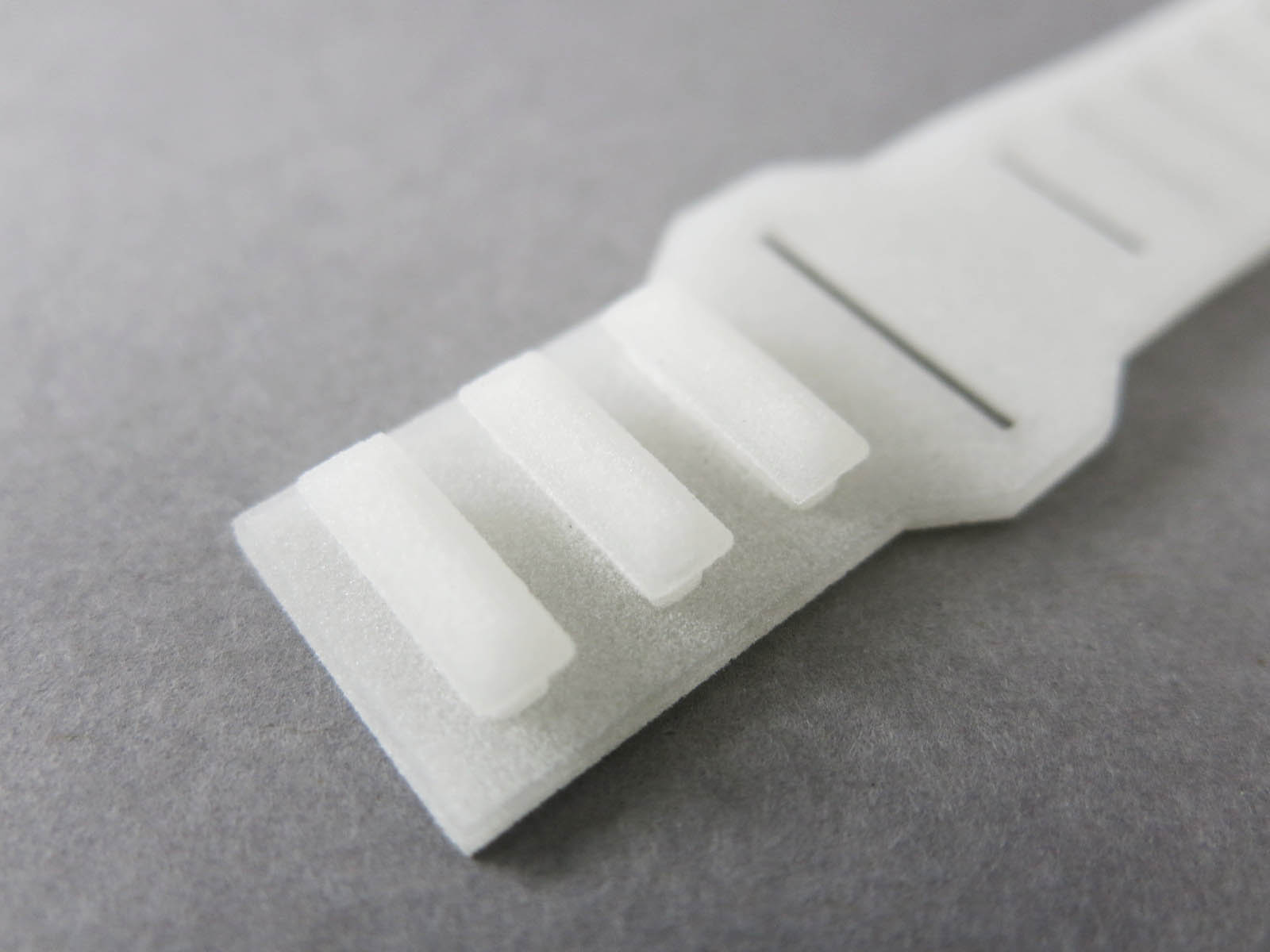

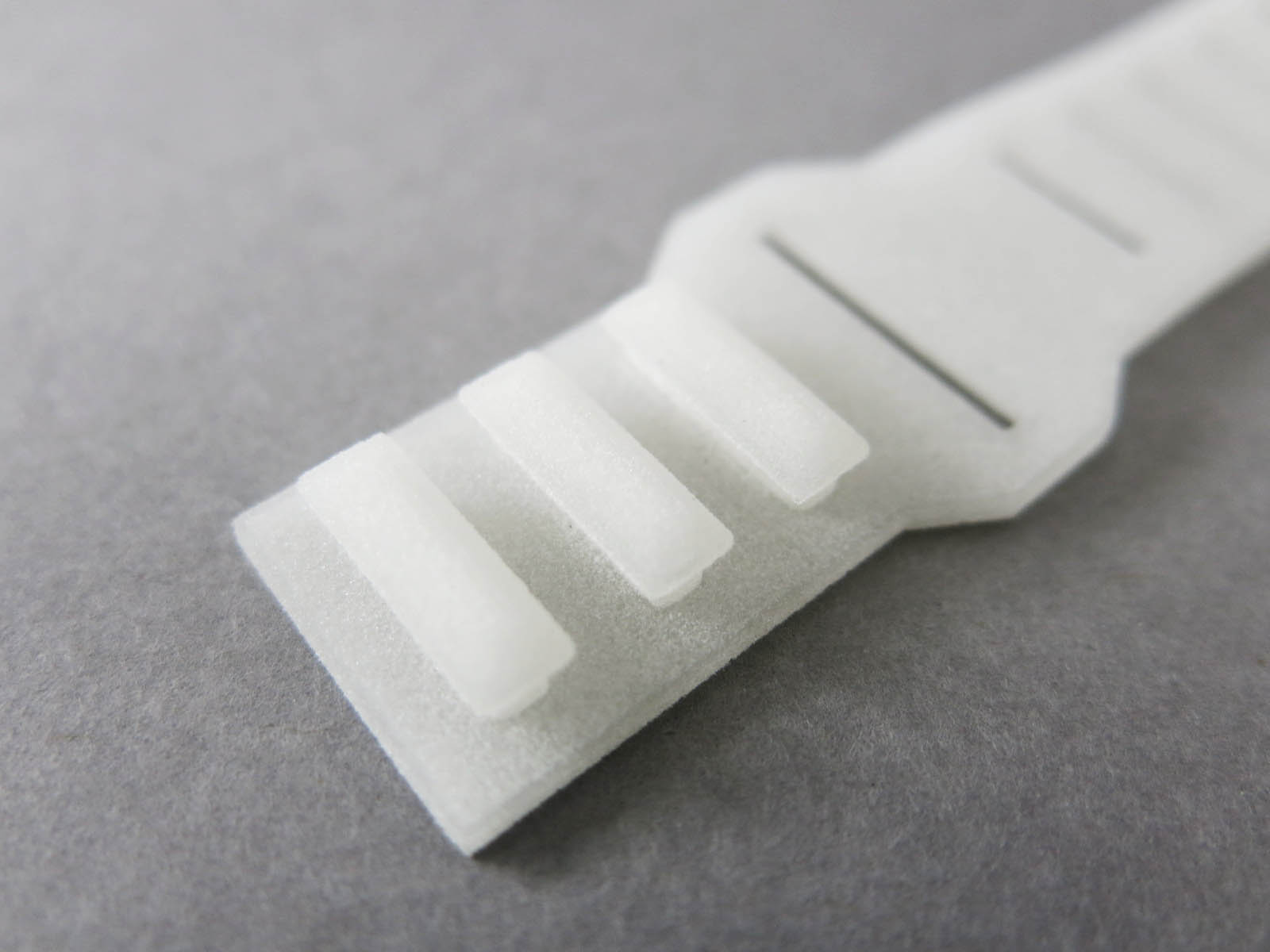

Every once in a while, a new material appears on the 3D printer scene. Now Sculpteo introduces one: PEBA.

PEBA, short for Polyether block amide, is a thermoplastic that has some very intriguing properties. According to Wikipedia:

PEBA is a high performance thermoplastic elastomer. It is used to replace common elastomers – thermoplastic polyurethanes, polyester elastomers, and silicones – for these characteristics: lower density among TPE, superior mechanical and dynamic properties (flexibility, impact resistance, energy return, fatigue resistance) and keeping these properties at low temperature (lower than -40 °C), and good resistance against a wide range of chemicals.

And according to Sculpteo:

The material is flexible and rubbery as well as resistant. PEBA is great for functional flexible plastic parts for both prototypes and finished products. The surface of PEBA is similar to rubber and can resist to stress and fatigue.

The material is both solid and flexible, unlike some of the other materials offered by Sculpteo. PEBA is great for both experienced professionals and beginning designers because of its high precision and low cost.

PEBA is typically used for sports equipment, which benefits from low density, flexibility and durability. It’s also used in other industries, including medical and electronics as a wire coating.

Some PEBA variants can also be anti-static, but it’s not clear that Sculpteo’s new offering is such.

Behind the scenes, however, the action is really at EOS, who supply some of Scultpeo’s 3D printing equipment. That manufacturer recently announced the availability of PEBA 2301 for some of their plastic machines. Their equipment uses the SLS process, in which a high power laser selectively sinters a flat powder bed of PEBA particles.

What I’m wondering is whether PEBA can be made into a 3D printer filament that could be used on the more common extrusion equipment. If the engineering properties of PEBA are good for EOS and Sculpteo clients, they should be good for others, too. Unfortunately, I was unable to identify a source of PEBA 3D printer filament.

Therefore until that happens, you’ll have to get your PEBA parts from Sculpteo.