Research that could lead to true human organ 3D printing begins with a method of reliably 3D printing shapes.

The problem with bioprinting is that a functioning piece of living tissue is not made from only one type of cell. In fact, you’ll find many different types of cells, each providing particular benefits that all add up to the function of the tissue.

It’s no wonder we haven’t seen 3D printed organs yet because bioprinting technology has not been able to reliably place cells within a design. Once placed, living cells tend to move around, and that can corrupt the structure.

And if your 3D printed cells are moving around, what’s the point of attempting to print a precise 3D configuration of different cell types?

Now that could change with some rather interesting work that presents a method of precision geometry for bioprinting.

The concept involves several stages, but it appears to be a feasible approach, not only technically, but also financially as low cost components and procedures are employed.

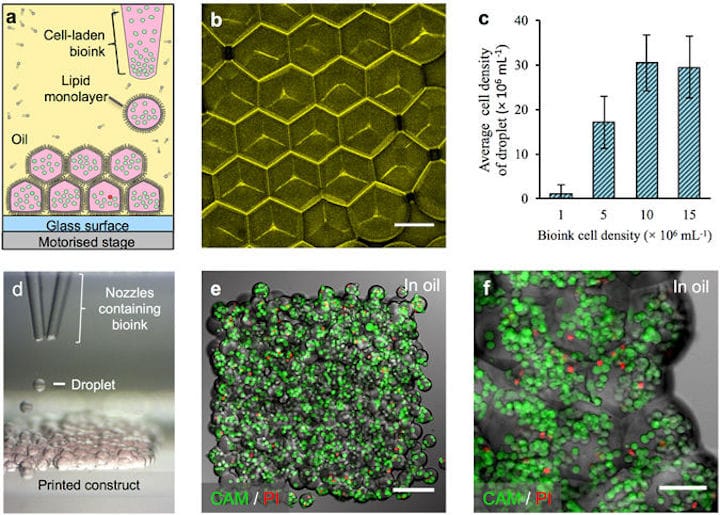

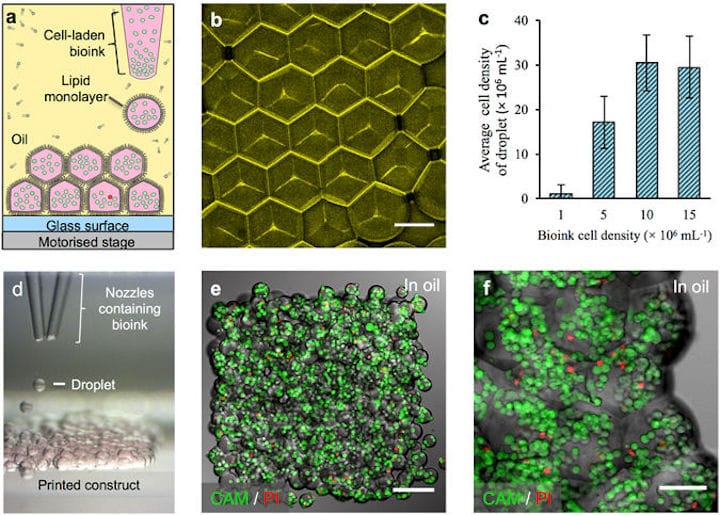

First, a collection of living cells are placed within droplets, which themselves are coated with a lipid.

These coated droplets are then 3D printed using conventional bioprinting techniques, which typically involve a microscopic syringe to deposit the material. The printing takes place within a volume of oil.

Then things get interesting. According to their paper:

The dispensing nozzle ejects cell-containing bioink droplets into a lipid-containing oil. The droplets are positioned by the programmed movement of the oil container. The droplets cohere through the formation of droplet interface lipid bilayers.

Aha! The lipid coating provides a means to hold the droplets steady in 3D space. This is the key feature of the approach, which allows a desired geometry of cells to be reliably 3D printed.

The printed structure is then coated with a thin gel layer for transport to a culture medium that can provide nutrients for the hungry cells.

While this appears to have been perfumed with one type of cell, there is now little stopping one from including multiple syringes containing a selection of different cell types. The combination of multiple cell types and precision geometry means one could attempt to 3D print more complex functional human tissue.

As always, this work is only research at this point. While it is clearly not a product, it seems to be a very key step on the journey to 3D printed tissue.

Via Nature