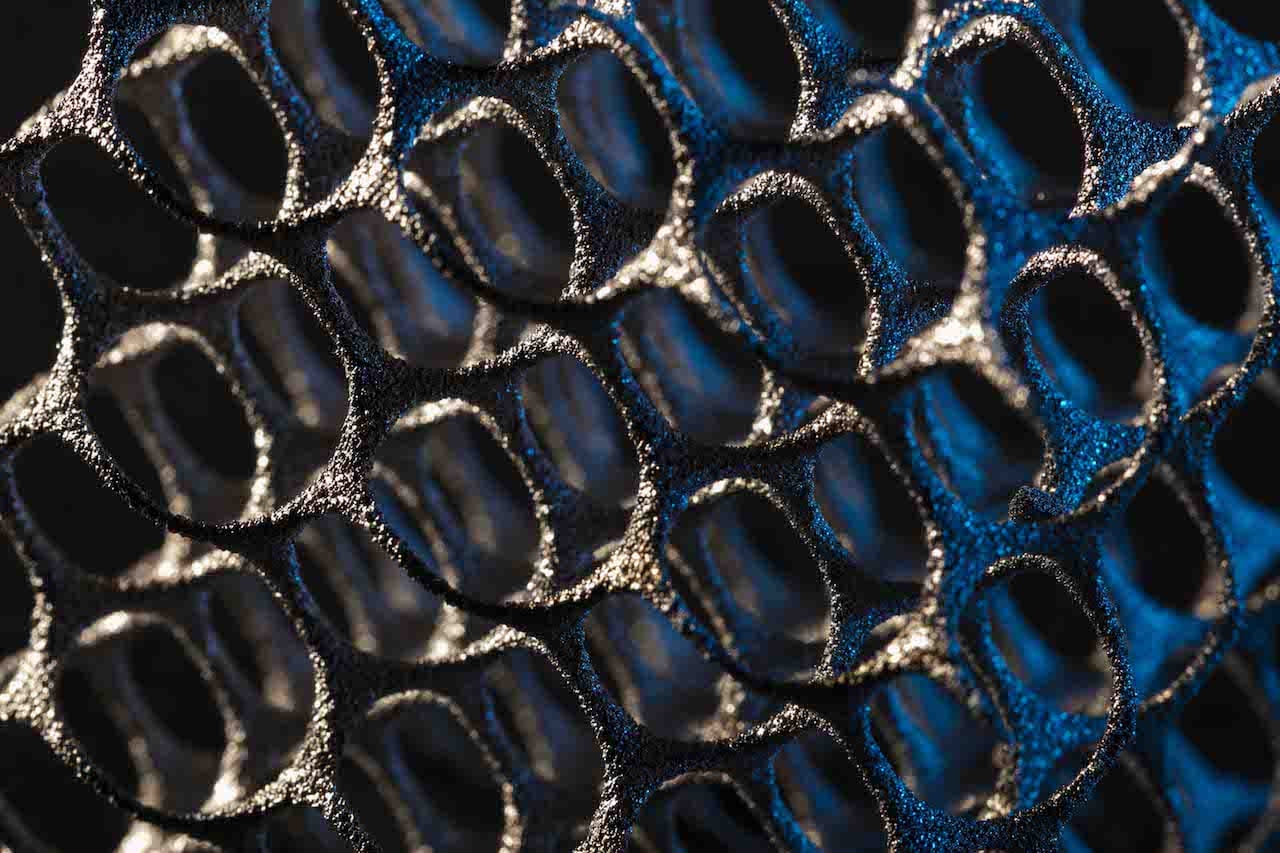

GE is now leveraging its assets to promote 3D metal printing.

Last year GE made the news by purchasing not one, but two of the leading independent 3D metal printer manufacturers, Arcam and Concept Laser. Even better, Arcam came with a metal powder provider, AP&C. They actually made a good try on picking up a third company, SLM Solutions, but the deal fell through at the last minute.

GE has moved those companies into “GE Additive”, a division that now makes those 3D metal printers. The division also works to develop better ways of using 3D metal printers, primarily for its own use.

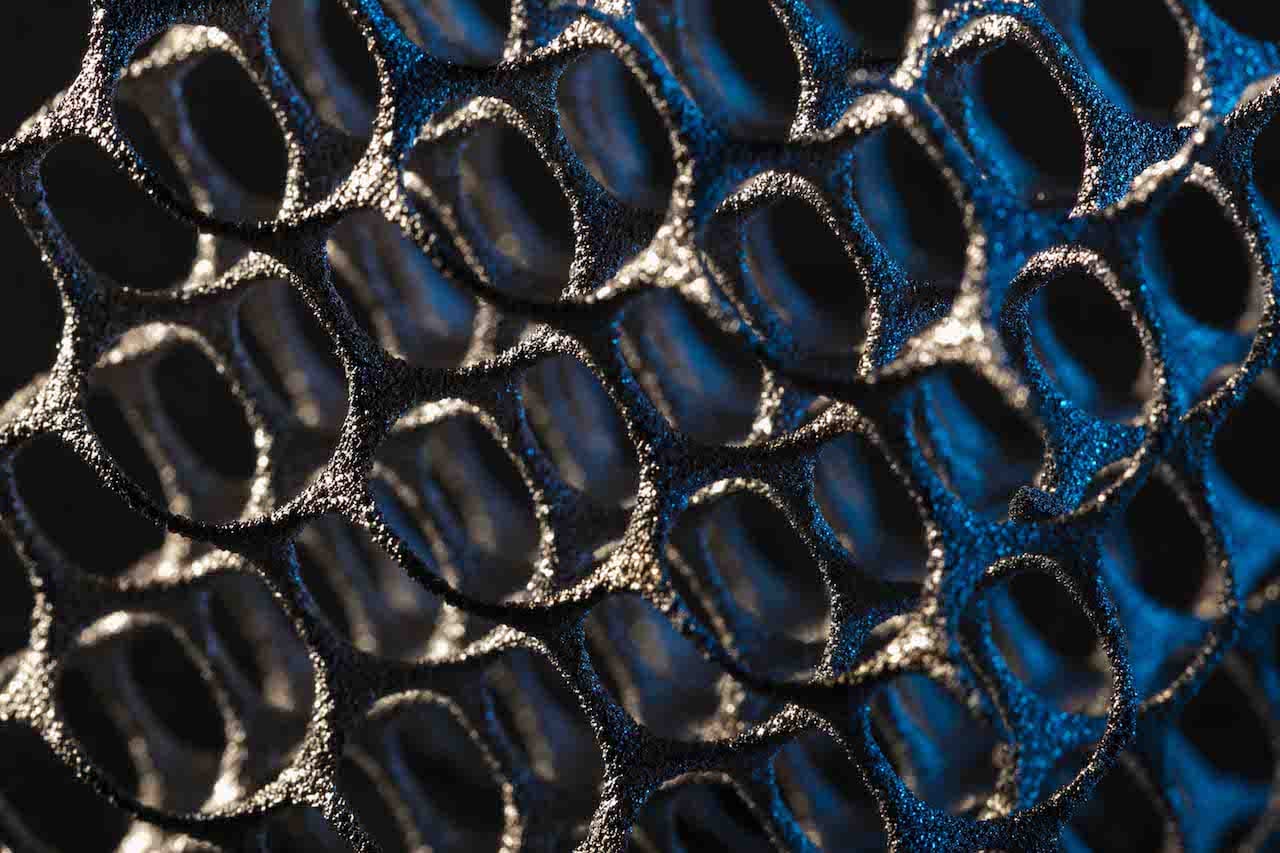

One of GE’s biggest industries is, of course, aerospace, where they obviously hope to leverage their new acquisitions to produce revolutionary new aerospace parts that are lighter, more powerful and far less complex to maintain. It’s a huge competitive advantage.

Industries are taking notice of GE’s venture into 3D metal printing and as a result interest in the topic has skyrocketed in the past year, with the most profitable segment of the 3D printer manufacturing market being 3D metal printers.

Now GE has taken an interesting step to leverage their position in the industry:

GE Additive is actively selecting companies to become certified additive production centers for its customers.

GE is now working to certify several companies by year’s end, creating a network of additive production capabilities across many industries and regions.

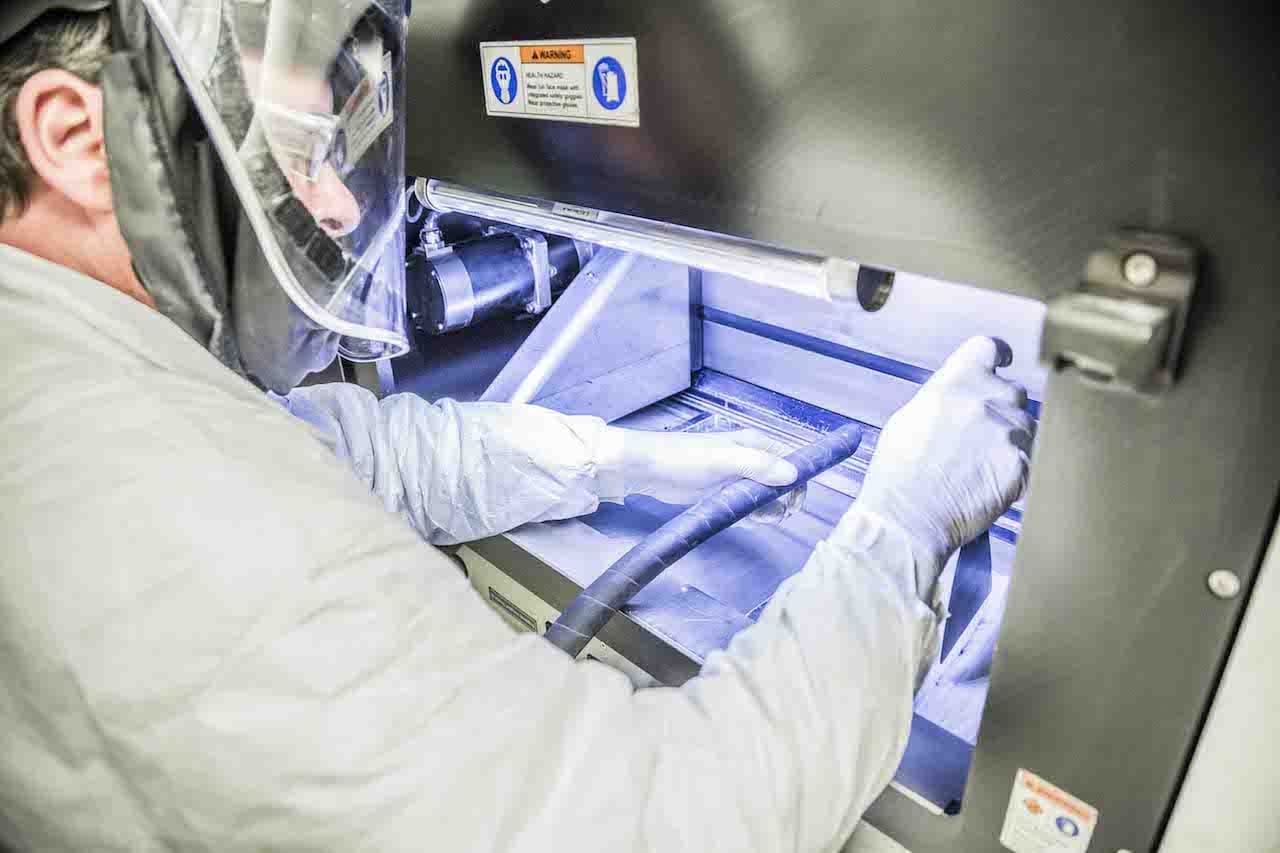

Each certified production partner will operate additive machines from Concept Laser and Arcam, use additive material from AP&C and benefit from orthopaedic best practices developed at DTI. The centers will be held to the highest quality standards and will receive guidance and advice from GE’s additive design and manufacturing experts – enabling them to deliver world-class additive parts and service.

Apparently GE Additive themselves do not produce 3D metal parts for customers; they only supply machines and materials so clients can do so on their own. And, I suppose, they produce parts for their own internal GE Additive purposes.

These production centers will most surely make extensive use of best practices learned by GE Additive’s labs, making everyone more effective in a domain that’s frequently complex and very expensive to operate within.

With the certification of “additive production centers”, it provides a massive way GE can sell far more 3D metal printers from their new acquisitions. Note that the announcement text specifies that these centers will use operate GE-manufactured 3D metals printers – and even use GE metal powder.

That’s a guaranteed market for them, as the GE brand will certainly attract clients to these new production centers.

The results will be more sales of machinery from GE Additive, which will help drop the internal cost per machine – making GE’s internal use of 3D metal printing lower cost, perhaps lower than their competitors will be able to reach. That’s what’s really going on here.

GE is taking a long term strategy here, but in the meantime it’s going to be challenging for their 3D metal printer competition to keep up if GE keeps growing their coverage in ways like this.

Via GE Additive