After coming out of stealth in 2016, Rize has been in the process of making its name well-known and its Augmented Polymer Deposition (APD) technology widespread.

So far, it has been successful in attaining such high-profile customers as the U.S. Army, the U.S. Navy, NASA and Merck.

However, along the way, Rize also had a change of management, parting ways with former CEO Frank Marangell in 2017. In fall 2017, the startup filled that gap with Andy Kalambi, who has over 25 years of experience in general management and executive positions. These include time at Dassault Systèmes as CEO of the ENOVIA brand and the global executive of the 3DEXPERIENCE platform.

ENGINEERING.com spoke to Kalambi about his vision for the company as he takes the reins.

Blending Two Technologies

APD is a unique platform in that it combines two existing 3D printing technologies, FDM and inkjetting. With APD, an extruder-style head is used to melt plastic onto a substrate layer by layer, while an inkjet print head can apply inks, such as color or functional materials. The result has enormous potential.

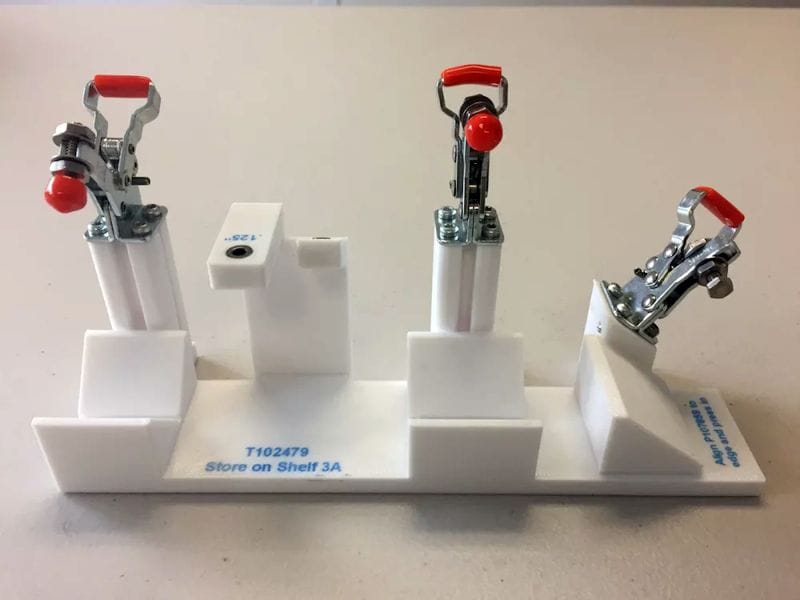

With the flagship Rize One 3D printer, APD already demonstrates a number of capabilities: printing images and text onto 3D-printed parts, creating easily removable support structures and isotropic strength. Post-processing is minimized through the deposition of the Release One ink between supports and the printed object during printing.

“Our first printer already does a lot in terms of delivering very strong parts,” Kalambi said. “If you look at reports of other parts produced by printers that claim to have the strongest parts, ours are two times the strength of those parts and even more. We are able to deliver this now and at a lower price point. We’ve also been careful about the cost of ownership. If we want to make the printing process pervasive, then we need to ensure that it’s available at a starting price point where it is affordable enough to put next to a desktop.”

Right now, Rize is working with its first engineering-grade material, Rizium One. The exact chemical makeup of Rizium One has not been disclosed, but the company has elucidated some specifics. For instance, the material is described as being twice as strong as Stratasys’ ABSplus and having a moisture absorption uptake of less than 0.01 percent in 24 hours, compared to 1 percent in ABS, Kalambi said.

Rizium One is also recyclable and does not emit any volatile compounds when printed. This compares to ABS, which releases toxic styrene as a by-product during printing. Additionally, the use of Release One ensures that no harsh chemicals are necessary for post-processing. The use of recyclable engineering-grade material and minimal post-processing at a low price point ($33,000) makes APD desirable to its customers.

This is just the beginning according to Kalambi. The combination of FDM and inkjetting makes it possible to innovate both in terms of the materials that come out of the extruder and the inks that are deposited during the printing process.

Read more at ENGINEERING.com