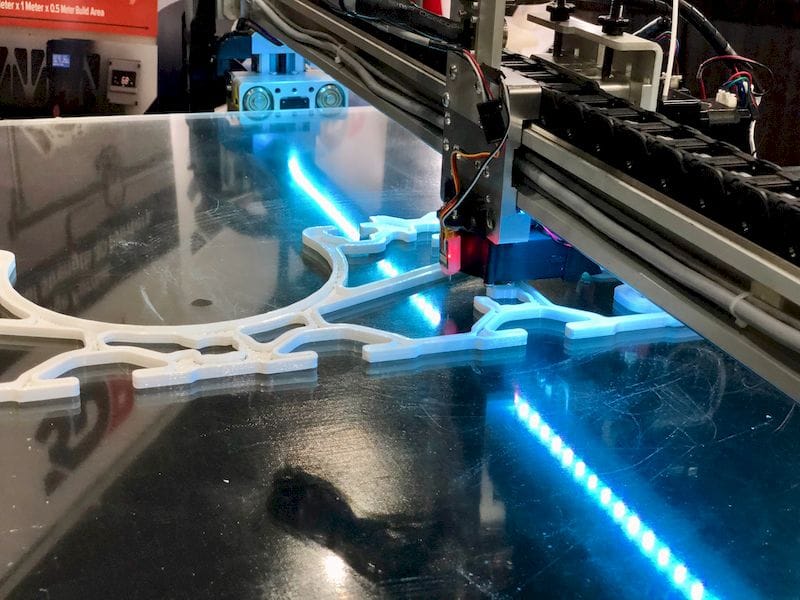

While extrusion-based 3D printers have been around for decades, there is still the need for some exploration, especially when it comes to large-scale printing.

We had a discussion with representatives from 3D Platform at Solidworks World 2018, and while the company hasn’t announced any new products in recent days, they apparently have been exploring the science of “fat” 3D printing.

3D Platform is one of the few companies producing very large-scale extrusion-based 3D printers. They began by simply scaling up existing designs, but immediately found a vexing problem: large prints take a very, very long time to complete.

Since then, they’ve spent years working on this problem. They switched to larger nozzles to extrude more material per second; they designed new hot ends capable of heating more rapidly passing filament; they used larger-sized spools; they even experimented with pellet feeding systems.

But in all this, they realized that the design and 3D printing rules change subtly when doing all these things. Some parts turn out stronger, while others become weaker.

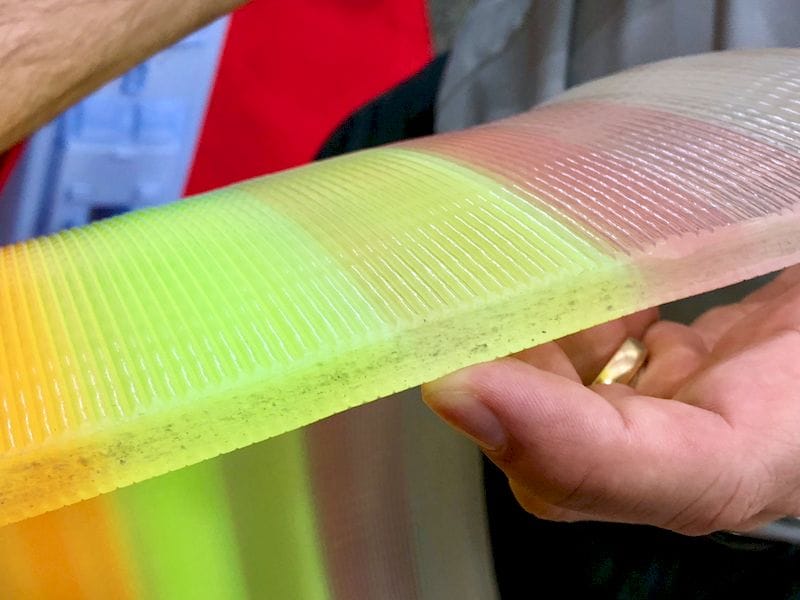

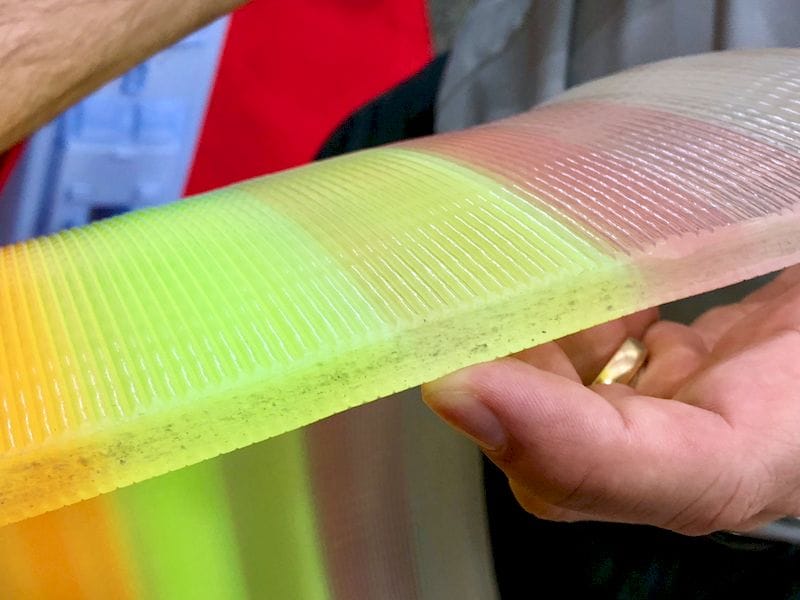

For example, consider the notion of larger nozzles. These extrude a much thicker bead of thermoplastic material than you’d receive with a typical 0.4mm nozzle. 3D Platform found that the cooling occurs at a different rate due to the surface area to volume ratio. Thus, you cannot 3D print overhangs as easily, since the most recent extrusions are still warm and soft.

Another issue is the gaps found with larger extrusions. Normally this is not an issue, but it could be with larger-sized extrusions.

There are a host of similar issues they’ve discovered, and they’re trying to determine methods to overcome them, which usually means adjustments to 3D printing parameters. 3D Platform has partnered with UCSD and Warwick University in the UK to get academic assistance in this area.

In the end, this all depends on the geometry of your part, the method you’re 3D printing with, and the goals of your project. But I’m confident that 3D Platform will be able to figure out the best ways to move forward.

Via 3D Platform