Canadian researchers have discovered a method of producing unusual magnetic objects using 3D printing techniques.

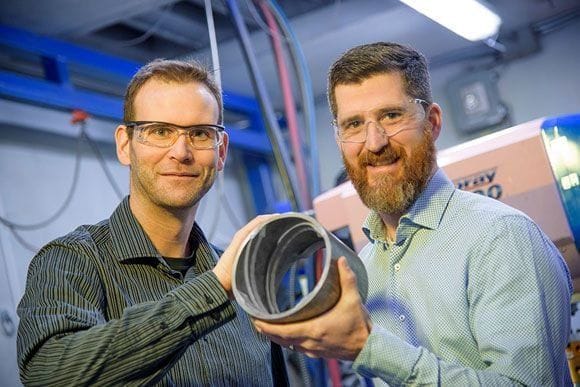

Researchers from the Canadian National Research Council have used a supersonic spray technique to form magnetic shapes additively, rather than the traditional methods of injection molding or powder compaction.

The powder is blasted at a high velocity towards a target, where the kinetic energy fuses the particles together in a gradual manner. Using a robotic applicator that moves in three dimensions, the applicator can create arbitrary geometries – to the tune of several kg of metal material per hour. The result is a highly functional magnet. They explain:

Another advantage to the National Research Council’s cold sprayed magnets is that they have excellent mechanical and thermal properties. The high velocities used in the deposition of the material and the absence of polymer in the material matrix combine to give the magnet intrinsic mechanical properties that are far superior to conventional magnets. The adhesion of the magnetic material to the surface of the part is exceptional, since neither glue nor assembly is used. Magnets created using cold spray additive manufacturing are easy to machine when compared to the more brittle sintered magnets. The NRC technology also offers magnets with increased thermal conductivity which allows for better temperature control. These magnets are corrosion and oxidation resistant and will therefore have a longer lifespan.

This approach can also be used to apply a magnetic element or a magnetic coating to an existing part.

Current manufacturing constraints on magnets have no doubt restricted the applications of magnetic technology. If this new approach catches on, it may result in some very interesting approaches, not only because arbitrary magnetic shapes can be produced, but also because even more rudimentary applications could be produced at lesser cost.

Via NRC