There are times when complex objects cannot be 3D printed.

I encountered one case of this recently when reading a post on a Personal UAV forum, where someone was attempting to design and build a new experimental propellor.

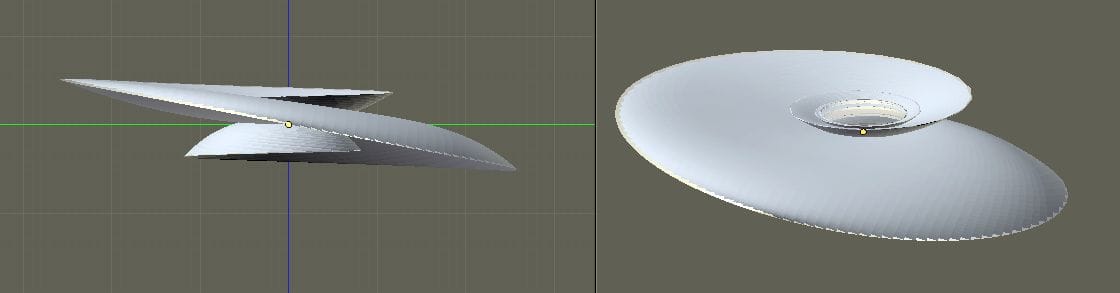

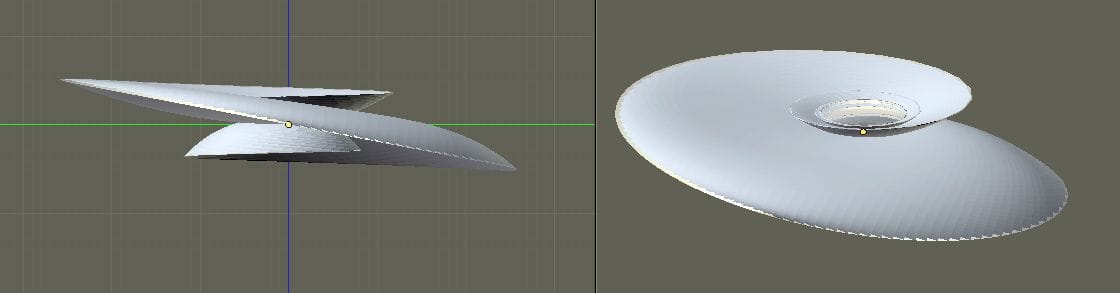

Designer Jan Kokes was attempting to create a drone prop that echoed the Renaissance design made by legendary Leonardo Da Vinci, a kind of very thin spiral encompassing large radial sweeps. It’s a very unusual design I have not seen on any drones, and certainly worthy of an experiment.

Making such a propeller may pose a challenge, however, due to the unusual shape. Kokes considered 3D printing it, having created the 3D model in Blender. But then:

The problem arose when I contacted Shapeways, since they have no 3D printer that would be capable of printing in such detail. CNC mill is out of question due to slimness of the blades that would vibrate violently during milling operation. I thought the most reasonable approach would be to make higher resolution 3D printer.

Evidently the thickness to width ratio was problematic, and Kokes had to seek other means of producing this unusual part.

Seven weeks later, Kokes added:

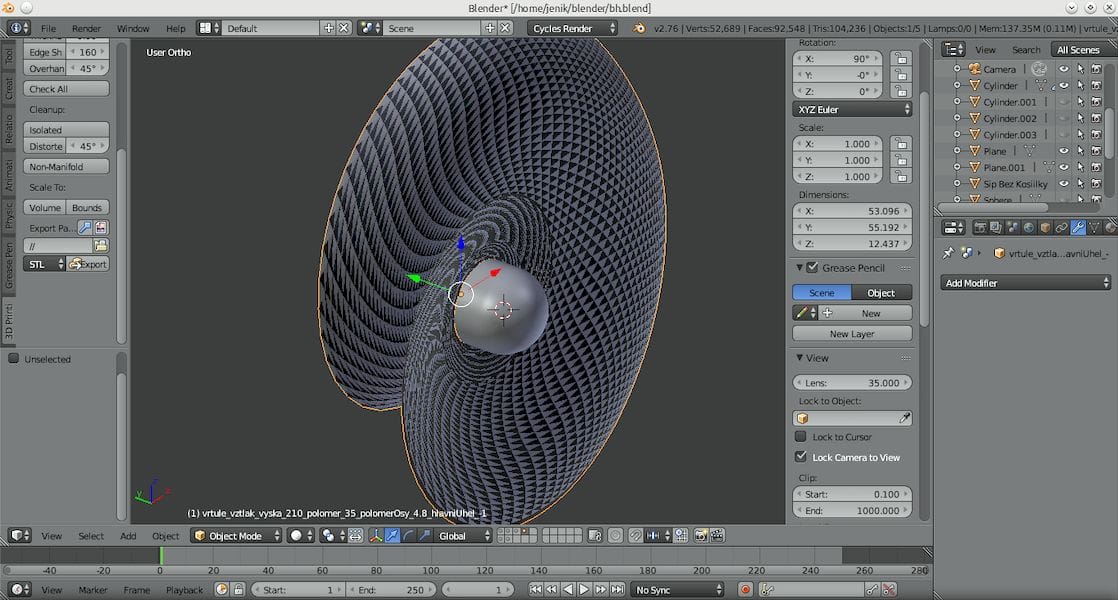

It took a while, but I have the mold in 3D. It wasn’t easy. I don’t need the prototype any more, I can simply cast real object.

He doesn’t say, but I suspect he 3D printed the mold instead of the object, which adds a step to obtaining the final object, but at least you can execute.

This common scenario illustrates a few important points about 3D printing.

First, 3D printing is only a tool. It’s one of many in the arsenal of a maker, although it is a powerful one. Designers should always consider leveraging the right tools for the job and not default to 3D printing, because sometimes it is not the right approach.

Secondly, it’s possible to use 3D printing in ways that are less obvious. Making a mold to complete a project instead of simply printing the object is like looking at the problem inside-out. 3D printing is a tool for certain, but there are more ways to use it than you might expect.

Finally, this also demonstrates the limitations of current 3D printing technology and services. There are unfortunately still many intricate geometries that are problematic to 3D print, even with the best equipment. And of course, a 3D print service may not have the most up to date equipment on hand; use what you have, not what you hope for.

Via DIY Drones