They may look like sacks of latex over an overpaid actor, but superhero masks are the real star of any superhero movie.

They hide any facial blemishes and scars, plus they’re what kids recognize on the front of all the movie merchandise.

And yet, making these voice-muffling head covers isn’t as easy as it seems. Just take a look at Ryan Reynolds’ mask in the Deadpool movies.

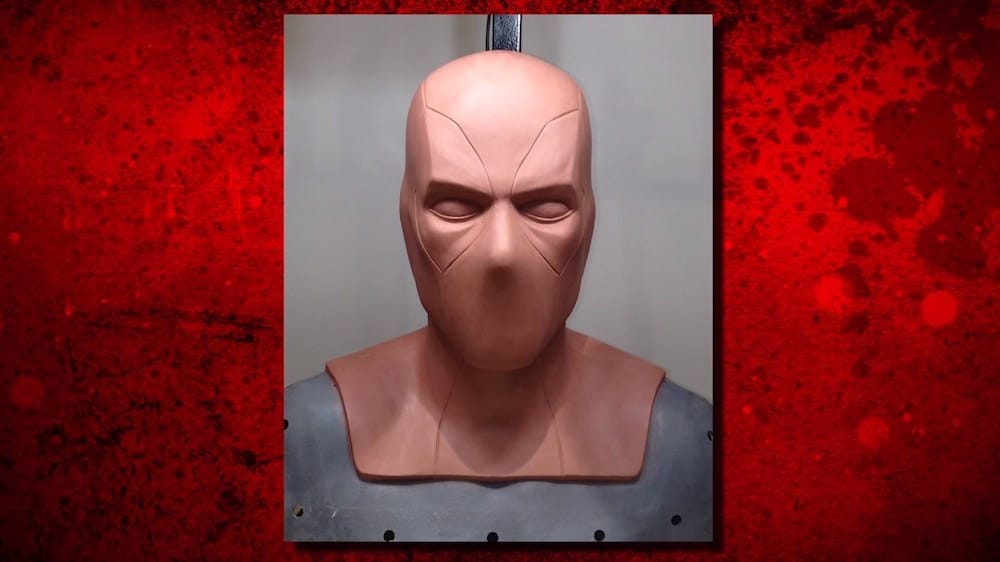

Even before filming starts, designers are already getting Reynolds’ face size and measurements to make sure the red mask fits him perfectly. They digitally scan his entire head to create a mold and sculpt on top of it using clay. The clay sculpture is then scanned, andf 3D printed to form the outer shell.

With the husk finished, they add features including different fabrics on the outside and inner workings which provide Reynolds breathing room to deliver his lines and room to breathe.

One of the coolest parts of the mask, however, is the interchangeable eyepieces which can be magnetically popped out to give the mercenary a wide range of facial expressions and allow stuntmen to see better through. These also come with mesh pupils, just in case a scene requires the character to blink uncontrollably.

Read the rest at SolidSmack.com