I’m reading a press release from Rize that describes a new service that performs “Make on Demand”.

Rize manufactures an interesting thermoplastic 3D printer that produces isotropically strong parts with a very easy to operate process involving quick break-away support material. They’ve been selling the machine to interested parties for a while now, and they’re of course mentioning successful sales such as their recent arrangement with Azoth Manufacturing. This is of course very good news for Rize, but not necessarily big news for everyone else.

But Azoth Manufacturing’s application of the equipment is quite interesting.

Azoth Manufacturing appears to be a venture from EWIE Company, a very large scale parts inventory service provider. According to their website, they currently “manage over 70,000 parts comprising millions of dollars of inventory at over 94 contracts globally”. It seems they provide inventory of spare parts for companies using specialized manufacturing tools, particularly for metalworking.

Inventory management is a critical issue, especially at large sized operations. A company wishing to maintain continuous operations would have to stock a number of spare parts on site to do so, but that could be significantly expensive. Worse, the parts would sit there unused for most of the time, effectively wasting use of that capital.

The inventory service allows for the sharing of commonly used parts among different users. So instead of each company keeping their own spares inventory, they all share one common inventory at a net lower cost.

When a participant requires a part, they simply order one. EWIE, I presume, keeps quantities of spares ready to go at strategic locations. But they more than likely attempt to reduce that cost by producing some parts on demand if they have the appropriate making equipment available.

It’s a great idea, but this Azoth Manufacturing venture seems to take the concept further.

They say they want to change the paradigm from “Order on demand” to “Make on demand”. What does that mean?

Order on demand would be the traditional model provided by EWIE, where the spare parts exist or could be readily made from known 3D designs.

Make on demand appears to be different. They explain three challenges they’re trying to overcome:

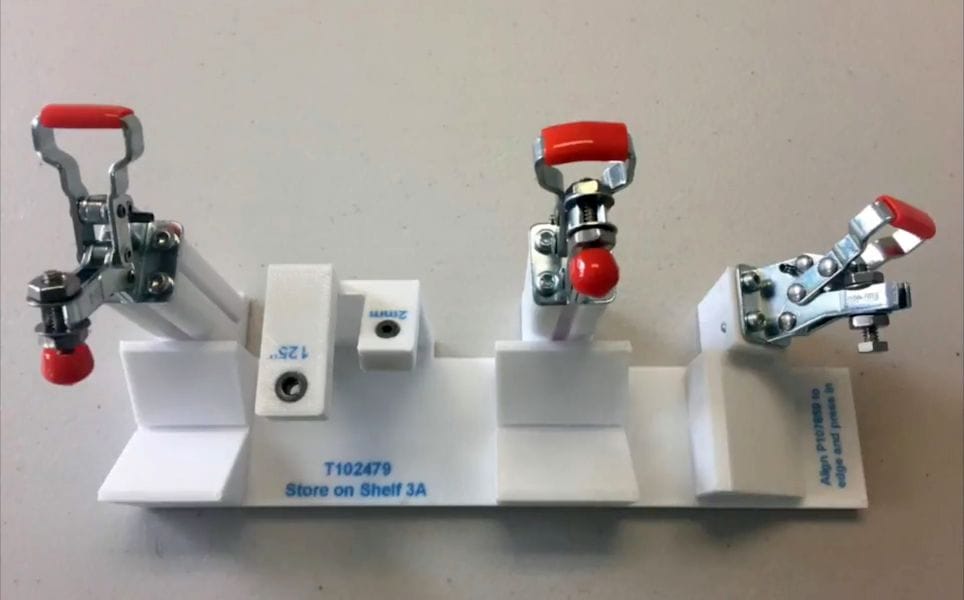

- Parts that need to be replaced when the original

- Manufacturer is no longer in business: machine spares, gripper fingers, gauge blocks, etc.

- Small-batch parts are not priced competitively due to the setup/lead times of subtractive processes.

- Highly complex parts cannot be made quickly by traditional manufacturing methods.

Aha – they seem to be creating a new kind of interaction with clients where they can literally build the required part on demand. They say they can provide (and likely have to) reverse engineer the part from an existing sample to obtain the 3D model suitable for 3D printing.

I find this business model very interesting, because it is quite different from “Here are my parts, keep some ready for me” to “Just make me one of these”.

This solves a huge problem that some businesses may encounter: something breaks and there is no known way to fix it. The Azoth model now allows for at least a good attempt at fixing the problem through the creation of a near instant replacement part.

All enabled through the magic of 3D printing.

Via Azoth Manufacturing and Rize (PDF)