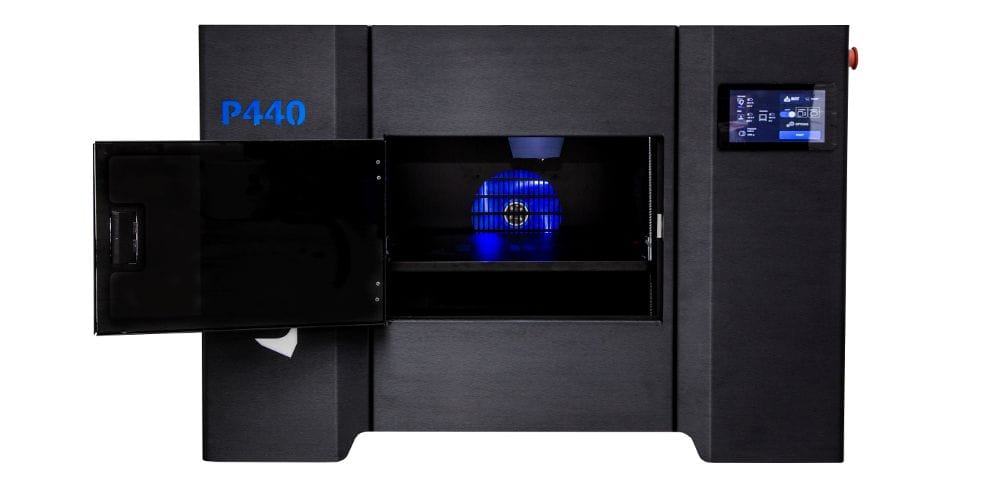

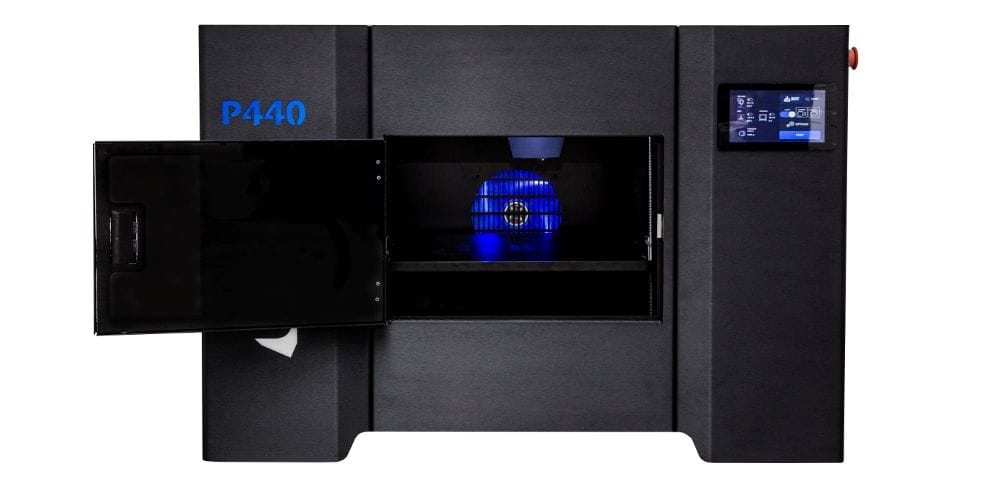

UBOT 3D is now ready to release their new huge P440 3D printer to the world.

The Krakow-based company has been producing smaller desktop 3D printers for several years, but earlier this year announced the giant P440 machine. It’s based on the same principles as the smaller machines, but significantly scaled up and including a number of interesting operational features.

The P440 uses the plastic extrusion process, and is able to make use of any filaments; it’s an open materials machine. It’s build volume is the key feature, being a massive 440 x 330 x 300mm, larger than most desktop machines, but a bit smaller than the truly monstrous 1m machines from a few other vendors.

A very important feature found on the P440 that’s not found on almost any other 3D printer is an independent heating system. While most 3D printers rely on stray heat from the print surface as captured by an enclosure, the P440 instead explicitly heats the build chamber with a 1500W system. The heat is distributed evenly throughout the chamber by the use of fans.

In other words, this device includes active heating. It’s quite rare because for many years Stratasys had a patent on heat control. This is why most machines use the “stray heat” method: to avoid patent infringement. Now that the patent is expired, companies like UBOT 3D can install an active heating system freely. However, for some reason few have gotten around to it yet, unlike UBOT 3D.

The print surface is of high quality, as it includes a 6mm thick solid aluminum plate equipped with an 800W heater for up to 150C bed temperatures. On top of this is a magnetically attached adhesive sheet for easy print removal.

Their “Hercules” extruder is designed to operate in higher temperature situations, making it possible to work accurately within the hot build chamber.

Their hot end sports not just one, but two heating elements, and is able to hit temperatures as high as 400C, making it feasible to attempt 3D printing high temperature materials, such as PEEK. We’re told they’ve already tested ULTEM, Nylon, Carbon nanotubes, ASA and other exotic materials.

The large size suggests swappable nozzles should be included, and they are: UBOT 3D offers a range from 0.1 to 1.2mm in diameter. The 1.2mm nozzle in particular will dramatically speed up prints, as it is 9X larger in area.

The P440 is a bit smarter than most 3D printers, in that it includes a significant onboard memory. Using this memory, the P440 can quickly absorb a print file from an inserted USB stick and run from memory. In other words, you can detach the USB stick while the machine runs! I don’t know of many other machines that offer this feature.

To make the machine more suitable for factory environments, the P440 includes a prominent power-off button, something that is often required by regulatory authorities.

Of course, the P440 includes the usual camera/networking/remote control features often found on other premier-level machines.

The P440 includes what might be the most sophisticated filament management system we’ve seen, at least for open materials. It includes a filament out sensor, which pauses the machine until you reload materials. It also includes a filament motion detector, which can detect when filament jams, tangles or otherwise stops moving. This is quite different from “filament out”; the filament is still there, but not moving correctly.

And a feature we’ve never seen on other machines: a weigh scale that measures the amount of filament remaining in real time. The user simply loads a spool and “it’s done”. The feature manifests as a warning that the filament is going to run out soon, and that action should be taken. What a great feature!

I’m not quite sure how they handle the different empty spool weights, but this is a terrific feature that every machine should include.

They say the machine can even order new materials for you, if required.

Up to now the P440 was available only in Poland, but now the company says they will be marketing it to the rest of Europe. I suspect they’ll be marketing it in the rest of the world sooner or later, though.

The price of the machine is €12,999 (USD$15,250) and we’re told there is an optional integrated materials storage and filament dryer module that will be bundled for €15,999 (USD$18,800) in the near future.

Via UBOT 3D