![A 3D model automatically re-engineered by Sunata to compensate for thermal distortion [Source: Atlas 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a838031be.jpg)

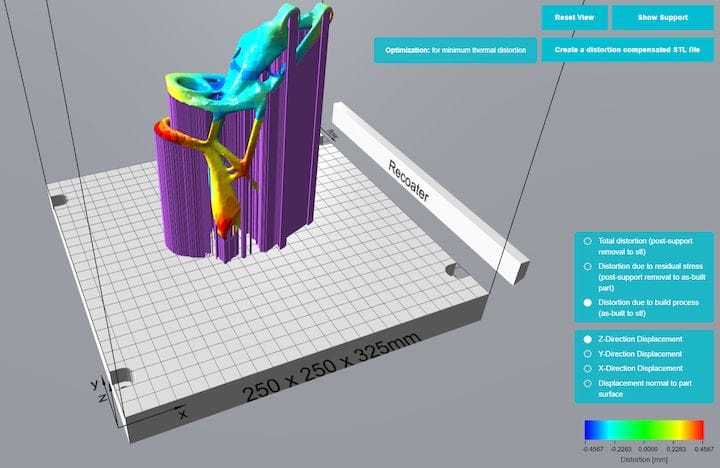

Atlas 3D announced a new version of their Sunata 3D metal printing optimization system, with some very interesting features.

Their Sunata system attempts to make metal 3D printing far more reliable by simulating the expensive 3D print operation before it happens. This is extremely critical on metal 3D prints, as the cost of a print – and failures – can be in the thousands of dollars each.

The objective is to obtain a successful print that includes the appropriate strength for the part, without distortion. Typically distortion occurs due to errant heat flows through the part and support material during printing. This can be severe enough in some cases to declare the print a failure, as it may warp beyond tolerances.

The answer is to simulate these and other effects before you even consider 3D printing. It’s far cheaper to iterate through simulations.

While the Sunata system is quite powerful, Atlas3D recently announced some changes that they describe as “pretty big”. Here’s a description of the major new features:

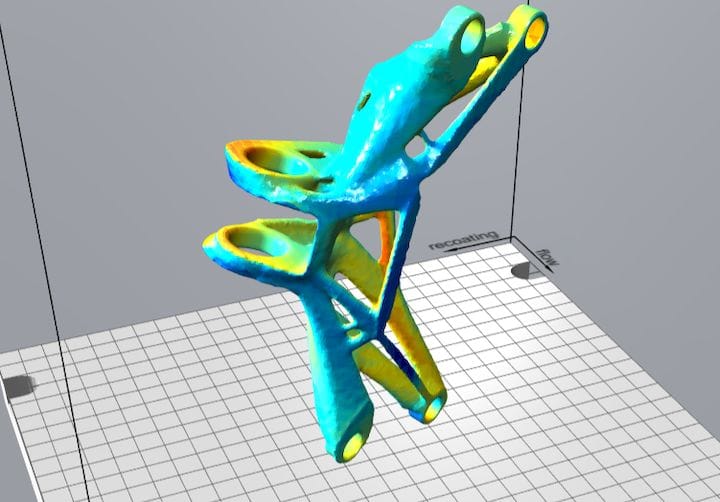

“Distortion Compensation”: Sunata normally optimizes to minimize part distortion, but even when finding the best possible orientation, you still have “some” distortion. The new Sunata has an option to allow the user to automatically rework their STL to compensate for the residual distortion and then re-run the simulation.

This is not simply predicting and reducing distortion, but actively compensating for it, making the printed result as close as possible to the original STL.

![Sunata has automatically regenerated the 3D model to compensate for residual thermal distortion [Source: Atlas 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a838d203c.jpg)

I’ve never heard of such an approach, but it is entirely reasonable. It’s in a way similar to how some thermoplastic machines will 3D print objects a bit larger than requested in anticipation of them shrinking when cooled, except that this is far more sophisticated.

Their new “Intelligent Nesting” feature allows for the assembly of a build plate job in a manner quite different than I’ve seen elsewhere. You can pile objects all over the plate, as other systems do, but here you can do that with a difference. You can, for example, indicate that this part is to be optimized for minimal distortion, while that part is to be optimized for minimum build time, etc.

In other words you can run a single job with multiple optimization targets for each part. This feature should allow more parts to be run through metal 3D printers on each job, making the system far more efficient technically and financially. This feature alone could pay for the Sunata software through operational efficiencies.

![Editing support structures in Sunata to optimize metal 3D printing [Source: Atlas 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a839251ef.jpg)

Atlas3D has also made a number of other improvements to the system, including laser speed and accuracy of results, and included a new support editing feature in which you can manually tweak generated support structures after the fact to apply any empirical knowledge to the situation.

The more I read about Sunata, the more I think I’d want to have it available if I were operating a metal 3D printer.

Via Atlas 3D

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.