![The SpectroPlast high resolution 3D silicone printer [Source: SpectroPlast]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a7c1e3cf3.jpg)

A Swiss startup has invented a rather interesting method of 3D printing silicone objects.

SpectroPlast, based in Zurich, is a startup company that’s developed a way to 3D print “any” silicone into complex objects. They explain:

“At Spectroplast, we developed a cutting-edge 3D printing technology that enables us to use any off-the-shelf silicone to produce readily functional products without the use of molds, cutting costs and time.”

And:

“We believe that 3D printing has the potential to shift focus from rapid prototyping to mass customization of functional products. With the world’s first SLA silicone printing technology, we expand the range of printable materials from rigid to stretchable materials. Vision: To bring industrial-scale silicone 3D printing to the mass market.”

How do they do it? There seems to be two parts to their solution.

![Example silicone 3D prints [Source: SpectroPlast]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a7c247d4c.jpg)

First, they take apparently any off-the-shelf silicone resin and pour in their secret, special additive. This prepares the resin for use in their printer.

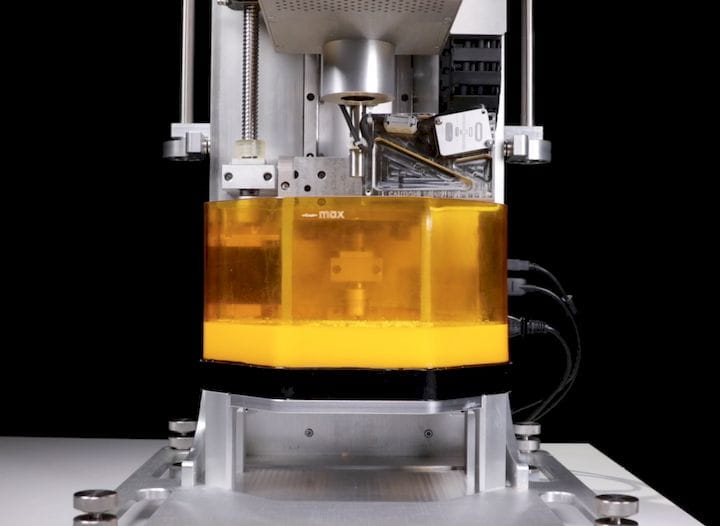

![SpectroPlast uses the top-down laser illumination approach [Source: SpectroPlast]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a7c294510.jpg)

That’s the second part, their printer. From the looks of it in the video it appears to be:

- A laser-driven resin 3D printer

- Uses the top-down lighting technique where the flat surface of the resin is illuminated

- A wiper sloshes fresh resin over top previous layers

- High-resolution prints are quite possible, with very little surface layering visible

![A wiper ensure fresh silicone resin is ready to print [Source: SpectroPlast]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a7c2e02dc.jpg)

This is quite interesting. The top-down lighting approach means they will not have resin tank erosion problems like many bottom-up systems. They will also be able to 3D print quickly, although not as fast as, say, Carbon, because each layer does require a “wipe”.

Their strategy seems to be to provide a powerful alternative platform for those manufacturing small but complex silicone objects. I believe this to be a good strategy, as clear identification of a business use case is incredibly important these days.

![Wonderful finely detailed 3D silicone prints [Source: SpectroPlast]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a7c33b457.jpg)

Their strategy could work well because we’ve already seen very significant interest in silicone 3D printing. One experiment using an extrusion approach by German RepRap 18 months ago resulted in a rapid deployment of a new product to accommodate significant demand.

The SpectroPlast system could be in higher demand because its prints are much higher resolution, and likely can be produced faster, too.

As of this writing, SpectroPlast does not yet seem to be marketing their machine, at least online. However, it seems like they will very soon, given the level of maturity it seems to be at today.

Via SpectroPlast