![Markforged CEO Greg Mark demos Blacksmith at RAPID + TCT [Image: Sarah Goehrke]](https://fabbaloo.com/wp-content/uploads/2020/05/markforged_img_5eb096ca79664.jpg)

Greg Mark, CEO of Markforged, tells us it’s “definitely the most exciting thing we’ve announced” as the company introduces its foray into artificial intelligence.

AI and 3D printing are increasingly coming together as Industry 4.0 continues to evolve. The new software introduction from Markforged is called Blacksmith; they call it “the first example of Adaptive Manufacturing.”

I caught up with Mark and with VP of Product Jon Reilly for a Blacksmith demo and discussion.

“Machines don’t know what they’re making,” Mark said. “Now we’re integrating AI: it’s a program to always make the right part.”

Building upon prior work in software, an area where Markforged is very busy, the team developed Blacksmith to address specific issues such as shrinkage following sintering of metal 3D printed parts. Accurately predicting potential sintering-related distortion is critical for keeping parts in spec — and creating a vast library of data.

“It’s not learning from one factory; we’re in thousands of factories, and Blacksmith is learning at the speed of data around the world. That is also done without sharing any part data,” Mark continued, adding that the AI learns from parts without conveying any proprietary information.

Blacksmith is designed starting with a focus on sintering issues for the Metal X and X7 machines from Markforged — but is applicable well beyond this one company’s 3D printers. Indeed, well beyond 3D printing.

“It’s designed for sintering, but why stop there? CNC is the next obvious step, then injection molding tooling,” Reilly told me. “We’re starting with 3D printing and have everything built in for that.”

Mark added that all told, Blacksmith represents “a new architecture” — and one that’s “totally badass.”

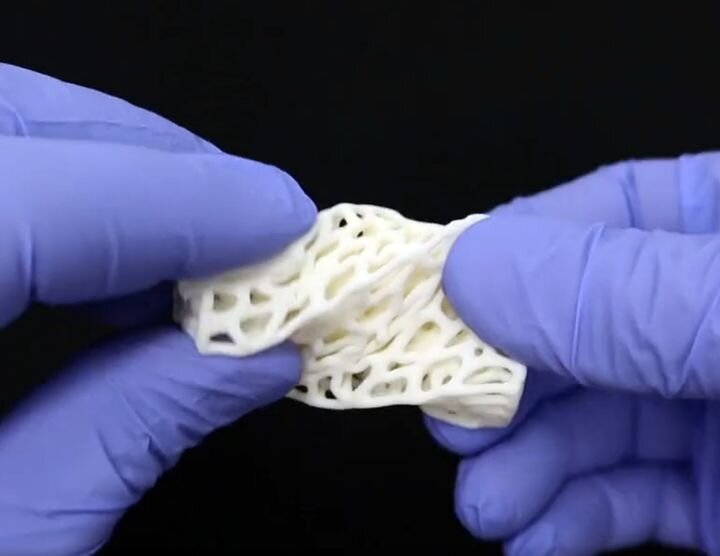

Mark scanned a metal 3D printed wrench, which fed into Blacksmith. The real-time scanning data subtracts out the background — in this case, the table and tool holding the wrench up — and ‘knew’ it was looking at a 12mm wrench. The scanned part could then be compared to the design, and Blacksmith can automatically adapt the end-to-end process to ensure production of in-spec parts.

Mark likens the process to the increasingly popular concept of self-driving cars:

“Like Tesla is building autopilot for cars, this is autopilot for manufacturing.”

So what does manufacturing think of it?

The general response, Mark says, has been I need it yesterday.

“People were excited when we released carbon fiber 3D printing; they were really excited when we released metal 3D printing. It’s off the charts with this. There were a handful of early customers we told in advance, about seven companies and government entities; they all said, ‘I need it yesterday’,” Mark said, adding that AI is “definitely the most exciting thing we’ve announced.”

The benefit of bringing artificial intelligence into manufacturing is that more data can be examined than ever before possible.

“It’s like throwing the brains of 10,000 machinists together,” Mark said.

Industry 4.0 and its associated technologies are set to ease the process of how we make things. Rather than worry about a more automated future, the Markforged team is really looking at advances like Blacksmith as the next stage of industrial evolution (and, I suppose, revolution).

“People say, ‘What will happen to people?’ Think of Ford’s assembly line; we can afford cars today because Ford made cars affordable. Now, a machinist can run not 10, but 20 machines. They keep their jobs in a recession because they’re profitable workers, they’re not babysitting machines,” Mark said.

Blacksmith will be available later this year.

Via Markforged

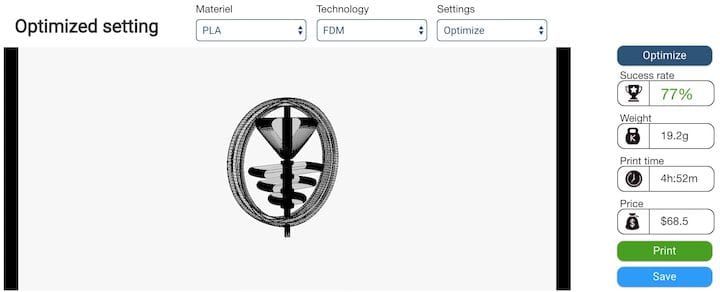

Additive Flow has unveiled a new generative design tool for additive manufacturing that has the unique ability to handle solutions for materials and mechanical design simultaneously.