3DQue is offering a “looping kit” to allow for continuous 3D printing on common desktop 3D printers.

Continuous 3D Printing

Continuous 3D printing is a form of printing in which little operator intervention is required because the printers clear themselves off after each completed print. The majority of the operator work required for a 3D printer is unloading prints and setting up for the next job. With continuous 3D printing, it’s possible for a device to spew out a stream of parts so long as material is supplied.

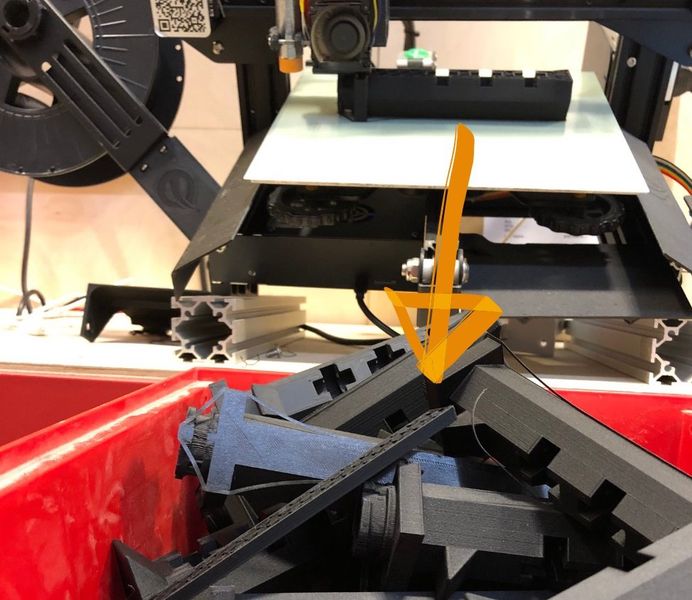

There have been multiple styles of continuous 3D printing, some involving belt conveyors, others with replaceable plates. But 3DQue has an unusual method that simply involves some simple tuning and mechanisms, as well as some help from gravity: their machines usually print sideways.

The goal of the company is to provide inexpensive manufacturing solutions through this technology. They can build arrays of inexpensive 3D printers equipped with their tech and suddenly create a powerful method of volume 3D printing. Here we see one of their array solutions:

In spite of their newness, the company has had some success in placing this equipment at several manufacturing clients. We’ve heard they’re pleased with the results, as considerable labor savings are obtained by using the 3DQue approach: hardly any operator time is required.

In fact, 3DQue told us they’ve recently completed a COVID-19 project in which they produced many boxfuls of PPE headbands on 36 3D printers over 1000 hours. During that time they required only 3 hours of operator time: 1.5 hours to swap spools when empty, and 1.5 hours of other maintenance time. That’s quite amazing and implies a full-time operator of their equipment could manage something close to 90 devices by themselves!

Specifications like that are quite attractive to organizations that operate large numbers of 3D printers, and the number of companies doing so is increasing. So too have 3DQue themselves, as they’ve been expanding their staff.

But what about those using only a single 3D printer? It seems that 3DQue has something coming up for them, too.

3DQue Looping Kit

They offering a “Looping Kit” that can be used to convert an existing 3D printer into a continuous 3Dp printer using their technology. The initial kit will be for the popular Ender 3 3D printer, but we’re told they will likely offer kits for additional devices, including Prusa, Ultimaker and others in perhaps the November timeframe.

The Looping Kit will not operate sideways, but instead at 30 degrees. Mateo Pekic, 3DQue’s founder and Chief of Innovation, says:

“There will be no surface treatments required, no scraping either. We’re carving out some features for hobbyists to use.”

Users with the Looping Kit installed will be able to send a “queue” of parts to the 3D printer, which should then be able to operate continuously and produce them all — if you have sufficient filament available.

It’s important to note that the software provided for this is not a slicer per se; it’s more like a controller that meters GCODE files towards the device.

The pre-sale for the Looping Kit starts October 20th at 2PM ET at the company’s site. The initial price will be a ridiculously low US$79, and that’s easily the least expensive method I’ve seen to create a continuous 3D printer. Of course, the price will rise a bit when the first batch are sold, but it’s still going to be a great deal.

Via 3DQue