In a today’s 3D printing world it is all too easy to focus too hard on the technical and forget other factors.

We, those deep into 3D printing, often spend effort trying to understand the details of 3D printing technology. That’s the speeds and feeds: filament diameter, resin wavelengths, build volumes, power requirements and more.

While this is useful to compare different machines in a given situation, it is really only part of the story.

What’s the full story? It’s that these machines do not exist solely as technological marvels, which many are indeed. No, the story is really about how they are used to perform a useful task: producing parts. That is to say, parts that meet the required engineering and quality factors.

3D printers do not by themselves produce these parts; the parts are made through a sophisticated combination of need, creativity, 3D design, 3D printing, production workflows, post-processing and other elements. All of these must be aligned in order to complete the job successfully.

Were we to focus only on the 3D printer, we’d miss those other steps.

I recently had a conversation with a CEO of a 3D printer manufacturing company who related a situation they had that emphasized this concept.

While a typical 3D printer sales transaction might focus on the specifications of the 3D printer in question, in this case a lot more investigation was done with the client.

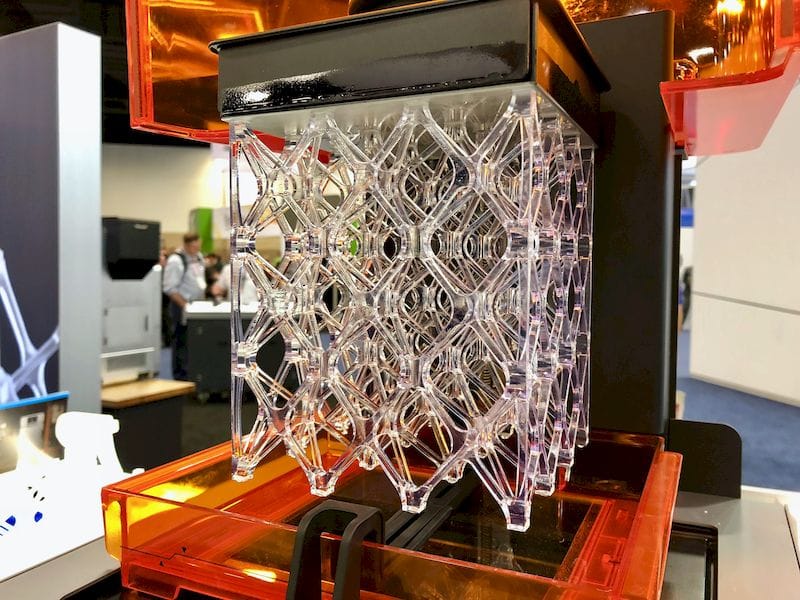

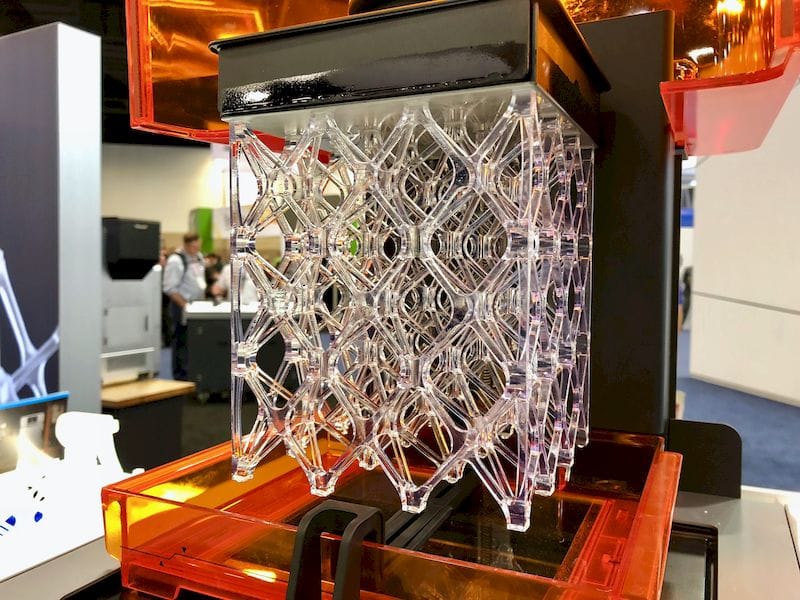

In this case the client was interested in resin 3D printers for use in a small production line.

That doesn’t sound particularly unusual in these days; any number of suitable 3D printers could be identified to fill that need. However, there was more to the story.

Typical resin 3D printers come with (or should come with) a post-processing station where the fresh prints can be washed of stray liquid resin and cured to hardness with a UV system. That’s a very standard configuration that is found in nearly every resin 3D printer setup.

However, this client was a bit itchy about the whole process. After some deep conversation, the CEO learned what the issue really was.

The small business owner was quite concerned about the resin post-processing setup. Like most resin 3D printer operators, they had to have many tubs of IPA to clean off resin. That’s normal.

Or so we technologists think.

That was not the case with this client. The small business owner simply didn’t like the idea of keeping large quantities of highly flammable IPA in their office. Yet they had been going along with that approach because it is the “standard way” of handling resin post-processing.

Leaving this flammable material overnight, each night, was just too much worry for this client. However, 3D printer manufacturers generally don’t seem to care about such issues: they are something for the client to sort out.

To me, this is one of the invisible barriers to 3D printing adoption: those who make 3D printers often don’t truly understand the environments into which their equipment will go.

In this case the CEO heard this story several times and realized marketing resin 3D printers with an IPA cleaning setup was definitely going to be a challenge in that specific market. And when you’re trying to make sales, any barriers possible should be avoided.

IPA was actually a barrier to 3D print adoption, rather than an essential part of the 3D printing process.

The CEO decided then to package their 3D printer products only with water-washable resin, thus permitting their clients to entirely avoid the IPA issue.

Water-washable resins are a new thing in the market and they’re not ubiquitous yet. Instead of using flammable IPA, you use commonly available water. Unfortunately the dirty water cannot be dumped down the drain, as it contains the potentially toxic resin and must be disposed of in special ways. Nevertheless, that disposal process caused less worry in this specific market, and so the use of water washable resins was the way to go.

The moral of the story here is that 3D printer manufacturers should listen a bit more deeply to their clients and prospects.

There are things to learn and things to change.