Formlabs announced some new resins for their dental and other users.

The company has focused on the dental industry for some time, having started with their first 3D printer as a general purpose device way back in 2013. Now their equipment has been used in many industries, but Formlabs has specifically focused on dental as their prime growth area.

By “focus” I mean they not only perform marketing in the space, but also provide different types of equipment: about a year ago they introduced the Form 3B, a 3D printer based on the Form 3, but with the ability to print biocompatible objects. That, of course, is a requirement for certain types of dental 3D printing.

Formlabs has also introduced a number of resin materials specifically designed for use in the dental industry to go along with the equipment.

However, these new materials can also be used by others in prototyping, manufacturing or engineering areas.

Rigid 10K Resin

The new resins include Rigid 10K Resin. This is apparently Formlabs’ hardest material. They say:

“Rigid 10K Resin is the stiffest material in Formlabs’ entire portfolio, meeting engineering and manufacturing customers’ need for a stiffer, more heat and chemically resistant material.”

This material goes along with their existing Rigid 4000 Resin, but is a lot stronger. One of their client testers, Mark Bartlett, President and Founder of Novus Applications, said:

“It was performing at a level that we hadn’t seen historically capable in the traditional Rigid [4000] material. I can print complex forms accurately, way faster than I’m going to machine them.”

Formlabs Draft Resin

Another updated material announced by Formlabs is their new Draft Resin. This material may sound familiar, as it was announced last year. Then, the company said this resin could allow 3D printing “three or four times faster” than regular resin.

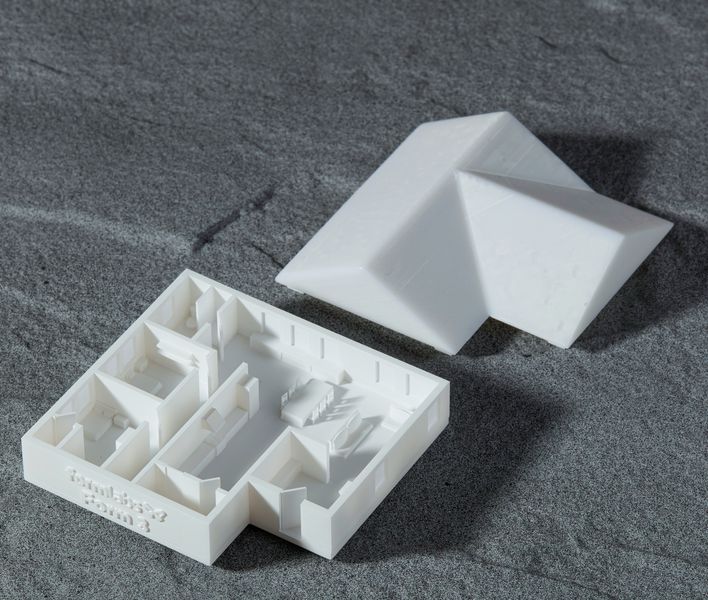

The idea was to quickly produce a “draft” print to ensure that it was correct before committing to producing the item in the final resin. This cut down the delays in prototyping somewhat.

Now, Formlabs has a new Draft Resin. They say:

“The reformulated Draft Resin enables users to print up to four times faster than currently available resins, while maintaining the highest degree of accuracy and improving part quality. The new formulation offers improved surface finish, postprocessing requirements, and a new grey color. “

Note they say “four” instead of “three or four”, so it does appear to be faster. Here’s a short video showing how the new Draft Resin compares against their normal grey model resin:

I must say that 3D print speed is not simply due to resin formulations: it also has a great deal to do with the print parameters, which Formlabs carefully tunes for each of their resin offerings. It seems they must have exhausted the avenues for increasing speed with the previous formulation via parameters, and opted to tweak the chemistry as well.

The results seem to be quite good, as the new formulation is not only faster, but also provides better quality 3D prints.

It’s fascinating to watch how materials gradually increase in quality. What might we see in another five years?

Via Formlabs