Gizmo 3D Printers has some major news to share in super-fast industrial DLP 3D printing.

It’s been a little while since we last caught up with the Australian team. We first met them at CES 2016, where in the startup zone they were showcasing live demonstrations of an unbelievably speedy DLP 3D printer — that prints, uniquely, from the top down.

Their offerings are interesting, but it seems like the team has been a little quiet. It turns out that’s because they were keeping their heads down as they were hard at work, and — phew. They have quite a lot to share now in terms of upgrades, new product launches, and add-ons to be released this year.

Ahead of our conversation, they sent over a few tantalizing points of discussion:

- We’ve doubled the speed of our already super-fast industrial, top-down DLP 3D printers – now printing up to 33 times faster than the average in the market

- Optional skins are now available for our machines with integrated PCs

- We’ve introduced an additional and exclusive 3D printing method to Gizmo 3D printers (which now has 3 in total)

- Released a Wiper/Recoater add-on

- NEW: The 1st 4K Industrial Grade Gizmo 3D Printers is hitting the market.This is big news because people can finally get an industrial 4k top-down DLP printer for less than USD $15 000

- NEW range of more affordable desktop options – we call it the GiziBuddy Range

- We keep on discovering more benefits of top-down printing. A research paper by a University has concluded that our top-down machine is better for ceramic printing for example.

“We’ve got so much news about developments we’ve been quietly working on,” Co-Founder and Managing Director Michelle du Toit told me as we started speaking.

4K Gizmo 3D Printer

The big, fast, high-resolution news is a new 4K projector version of Gizmo’s machine.

“We not only have UV HD projectors, we also have 4K projectors now,” Co-Founder and CEO Kobus du Toit explained. “It’s very low cost: you can get a 4K top-down DLP printer for less than $15,000.”

To put that in perspective, Gizmo points out that most industrial-grade 4K DLP 3D printers “can cost more than US$50,000” — and the “smallest and most basic 4K Gizmo 3D Printer [is available] for less than US$13,000.”

A few comparisons can be made as well between the new 4K version of the system and the original that debuted in 2016 as an already-impressive machine. Gizmo 3D Printers explains:

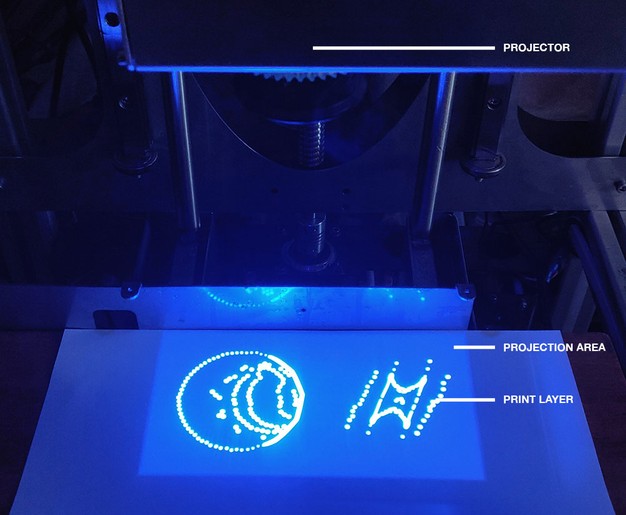

“Using a projection area size (refer to the image [above] to understand what a projection area is) of 192mm x 108mm as an example, the difference between printing with or without a 4K projector would be DOUBLE the resolution! The resolution of a Gizmo 3D Printer with an HD projector would be 100um XY. At the same projection area size of 192mm x 108, the resolution of a Gizmo 3D Printer with a 4K projector would be 50um XY. “

So that’s twice the resolution — what about speed?

“When we launched at CES I believe 2016, we were using Acer projectors, using a single projector, and had a super-speed projector option of two Acer projectors. A 100 micron layer would have taken 2 minutes,” Kobus explained — now, though, “with the current setup this takes 6 seconds.”

Michelle added to this speed discussion, noting that “Gizmo is already 33 times faster than other 3D printers out there.” She credits the top-down method for their success here.

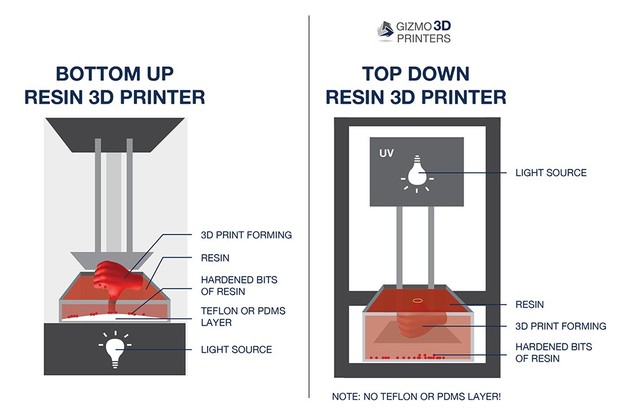

“We use the top-down method, which not a lot of 3D printing companies use, and which has proven over and over to be more efficient. We’re not only talking printing speed, but efficiency,” she said. “For instance, prints that are printed on bottom-up machines are exposed to suction forces caused by a peeling step in the printing process. It can cause the prints to be pulled from the build plate where it’s hanging upside down from and fall off. Our top-down printing method has no peeling step and prints are formed sitting on top of the build plate which means it has no risk of falling off. We can print as big as we want to without needing to worry that gravity might cause prints to loosen from the build plate as one could experience with a bottom-up 3D printer. Plus ours are some of the biggest DLP 3D printers available in the 3D printing industry.”

The 4K option is also available as an upgrade option for current Gizmo systems.

Gizmo 3D Printers

Further launches include a new Plus range to come this year, as well as more budget options.

“The Plus range is a fully enclosed system, mostly for universities and big companies that want a fully enclosed system,” Kobus noted.

The Plus range will be “very much high-end, industrial-grade” systems, including powerful internal systems. Rather than “a Raspberry Pi or something like that,” these 3D printers will have a full PC, and the “customer can upgrade the CPU to a higher version, and can upgrade memory; it comes with a 250gig hard drive, it’s a nice PC inside the machine,” Kobus added.

Because Gizmo 3D Printers have always been focused on customization — like, but definitely not limited to, that PC upgrade capability — this is a big area of updates.

“Most machines have a standard way of printing, we call that standard speed,” Kobus said. “We have a two-phase wiper or recoater printer so the user can change the printing method in a print as they wish. They can program the print for high speed, for high quality — for what they want.”

Sometimes in 3D printing, speed is more important than finish; think rapid prototyping. One major use for resin-based 3D printing systems, though, is finish, and so being able to change over to a highly detailed method is always in high demand.

“We have the recoater wiper system, which has been in the works for three years to make something upgradeable, configurable, and can be used with all our vats. It can be 85mm wide to 400 mm wide,” Kobus continued. “We can change the wiper on the machine to work with any of our vats, and the wiper has attachments to add a spray system in the future. We’re testing a spray system; that’s still in the works.”

The Wiper or Recoater add-on for Gizmo Resin 3D Printers is available for $800, and a step-by-step guide for installation is available.

Later this year, Gizmo is planning to release the GiziBuddy 3D printer as well.

The GiziBuddy, which can fit on a desk, is the smallest machine currently available from Gizmo. With different internals, the GiziBuddy 3D printer will have specific application focuses such as the GiziJewelry and GiziDental printers.

“Our machines are highly configurable. The customer can have a large vat in the machine and place another vat on that vat; the machine won’t stop you doing those kinds of things,” Kobus said. “We have what we call the ring vat, it’s the smallest we have now. You can put that on top of the bigger vat, and it only requires 700ml of resin. It’s also open to third party resins.”

Our relatively short chat was informative and almost head-spinning; their high speeds aren’t only for their 3D printers, but sheer amount of work to share. Which, as Kobus put it, was about “four years of work in five minutes.”

Gizmo 3D Printers is well worth the look for high-speed, configurable, affordable options in DLP 3D printing — there’s a lot that’s new there, and more yet to come!