Yesterday, Fabbaloo hit a milestone with 10,000 3D printing articles published, and we’re learning a lot about what this means.

There are some implications to read into here, with all this reading available, and it’s not just for us at Fabbaloo. That means there are 10,000 individual stories in this one resource alone — and we are one of many in the sea of additive manufacturing publications.

Consider that we’re one of the few relatively high-volume dedicated 3D printing daily resources out there, publishing upwards of two dozen new pieces each week. Think of some of our colleagues in this space, and that’s hundreds of new 3D printing articles each week. Fabbaloo, founded in 2007, is one of the older publications, but it’s also not the highest-volume by any stretch, so we’re surely not the only site to hit the 10,000 mark. In short: there are easily hundreds of thousands of articles out there from similar sites that are wholly focused on 3D printing and related technologies, even before taking into account those from general tech and other more mainstream sources.

In short, that means there’s an absolute wealth of information out there. This is both good and bad. Good — because obviously more informed decisions can be made with more information available. Bad, because that also means there’s some weeding through and vetting of sources to do to ensure that information is accurate and does not misrepresent the technology. (Think of the “a 3D printed house in 24 hours!!11!1!” stories that somehow still pop out and have some technically correct information but overall present something of a misleading picture of what’s actually possible; think of the stories from half-a-decade ago promising “a 3D printer in every house”; sources matter.)

We’ll continue to do our best here at Fabbaloo to present an accurate representation of what’s actually happening in the 3D printing industry, for better or for worse.

But it’s also a celebration, so let’s celebrate! Kerry shared some of Fabbaloo’s most-read stories, as well as several of his standouts from his time writing here yesterday, so I thought I’d do the same, even though my 500+ pieces published with Fabbaloo over the last nearly-two years is a far cry from his 8,100+ over 13 years.

Hands- And Feet-On Experiences

Unsurprisingly, my favorite pieces to write are those following direct experience with the industry. These pieces are especially nice to think on right now, when the pandemic is still keeping us physically distanced, as I’m always a major proponent of attending industry events (when it is safe to do so!) and visiting industry participants.

AM Center As Evolution: A Chat With XJet

Visiting XJet’s new AM Center in late 2018 was a real treat. The Carmel systems are impressive for 3D printing metal and ceramic, and seeing several installed in the $10M center highlighted the seriousness with which the Israeli company is approaching the industry. They’ve gained several intriguing customers since the visit, and I’m glad to have reported from the ground in Rehovot on their progress. Also, swimming in the Dead Sea was a major work travel highlight.

106,000 3D Printed Faces

I often focus on industrial 3D printing applications, so tend to see a lot of aerospace, automotive, and other pretty serious parts. Sometimes serious parts are rather whimsical, though, as was in the spotlight at LAIKA Studios. The 106,000 faces 3D printed for Missing Link provided the perfect expressiveness for the characters in this excellent stop-motion movie. LAIKA’s increasing use of 3D printing, since its start with Coraline, is breathtaking — and seeing all the movie sets, characters, and props up close and personal was a lovely reminder of the beauty possible through technology.

Initial Impressions: HP 3D Printing And Digital Manufacturing Center Of Excellence

HP’s sites in Barcelona are where the company’s 3D Printing business started — and where it continues to expand. The Center of Excellence opened last year was a real proving ground of collaboration, technological prowess, and the deep history of HP Inc. Multi Jet Fusion and Metal Jet systems were both running in the labs, but the most impressive part of this facility is certainly the brilliant minds at work.

Around Town With The OESH Townie 3D Printed Shoes: Review

Sometimes hands-on is feet-on, and such is the case with the review I did of OESH’s 3D printed Townie shoes. I still struggle to find negatives about these shoes, and they remain a pair of my go-to footwear on a daily basis. The ability to validate the long-term effectiveness of consumer-facing applications is greatly appreciated, and I’m doubling down on my statement that these are great shoes (as are the OESH Artemis sandals, which I’ve now had for two years and still adore).

Interviews

Keeping up with the personal theme here, I find the best value I can offer readers is through sharing information direct from the industry — and how much more direct can that get than via interviews with 3D printing leaders? I’ve conducted dozens of interviews already for Fabbaloo; here are just a few standouts.

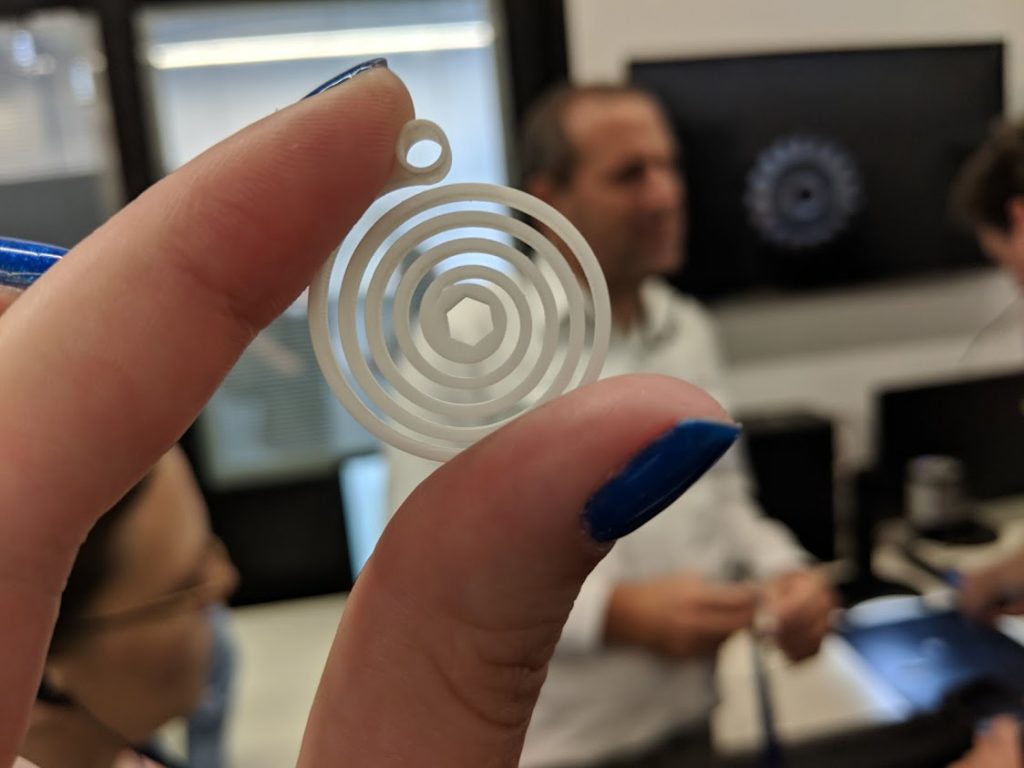

Lumecluster: Behind The 3D Printed Mask With Melissa Ng

When I started writing with Fabbaloo in August 2018, I did so with a series of interviews. Always, one of my favorite people to interview is the phenomenally talented artist Melissa Ng, who brings us her designs through her company, Lumecluster. She uses 3D printing along the way to creating exquisite masks and jewelry and, perhaps the most obvious standout, armor. Her work is a personal statement to the dreamer, and speaking with her is always an inspiration.

3D Printing And Synthetic Cadavers: In Depth With SynDaver

Turning to the other side of the coin, one of my most recent interviews was with synthetic cadaver manufacturer SynDaver, which has only very recently stepped directly into the 3D printing industry. The company introduced its open source Axi 3D printer just last month, and I spoke with the CEO about why they would make this move, how it fits into their business strategy, and what his thoughts are about some interesting moves in the industry.

Happenings

The 3D printing industry is always very busy, so we do our best to keep up with what’s going on, looking into current events and industry reactions. Obviously a major area of focus in 2020 has been the global COVID-19 pandemic, which has affected effectively the entire world — and has seen 3D printing step up as an immediate stop-gap manufacturing response for producing PPE and for longer-term use in mass production of testing swabs.

The Collaboration We Need: Consortium Propels 3D Printed COVID-19 Test Swabs

It’s almost impossible to pick among the inspiring stories from the 3D printing industry as so many have stepped up to help. This collaborative effort is indicative of both the spirit and the effectiveness of the industry at this time, though, as several major companies banded together to design, validate, produce, and distribute nasopharyngeal (NP) testing swabs and make them easily available.

Insights & Commentary

The 3D printing industry is filled with brilliant minds, and it’s a pleasure to share perspectives and expertise, as well as to share our own commentary.

Entering Additive Manufacturing

We all got started in additive manufacturing somehow, and upon reflection I found a few primary routes of entry into the industry. While earlier on in 3D printing many people sort of meandered in, increased access to educational resources and training from younger ages are seeing more and more people working toward the goal of getting into additive manufacturing careers.

Disruption Needs Noise

I spoke on a panel as part of Markforged’s Additive Manufacturing Day in October 2018, and it’s always a true pleasure to get together with like-minded people and an engaged and informed audience. One of the themes to arise from this event in particular was that for disruption to actually happen, it can’t be silent: there are reasons we talk about the growth and happenings in 3D printing.

Please Name Your Technology Something We Can Remember

Among the opinion pieces I’ve published over the years, this is possibly the one I’ve received the most direct feedback on from the industry. Several startups have reached out for thoughts on how to name their company and products in a way that stands out — in a good way. If we can’t remember your name, we can’t talk about you. Be clever, but not too clever for your own good.

The Real Value Of 3D Printing Patents

Patents in the 3D printing world are often met with mixed reactions. But they’re not always just a money grab, as was pointed out after Authentise announced a new patent last year. The thoughtful nature of this patent was interesting as an insight into Authentise’s business strategy, and certainly the openness of the commentary offered was helpful in really understanding where they were coming from with the patent filing — which was positioned really for underscoring the viability of technology more than for making money. (Not all patents filed make as much sense, naturally, so it’s nice to understand some of it when we can.)

It’s Nice To Be First In 3D Printing; It’s Better To Be Best

As 3D printing grows up as both technology and industry, we’re starting to see a slowdown in “firsts” — so when a company can’t claim “first!” what is there for them? To be the best, or the only, of course. It’s nice to have the debut offering, but that’s not ultimately where the competition is; as Fabbaloo friend Julie Reece pointed out from her perspective as an experienced and excellent marketing executive:

“Some marketing advice. When positioning your company, product or service, being the ‘first’ isn’t as important as being the ‘only.’ If you can be the ‘only’ to deliver a benefit that matters to your prospects you have a powerful foundation on which to build your marketing program”

This Is No Time To Stay Silent

(Emelia has since moved on to another opportunity but stands with us in delivering this message)

Finally, I’d like to end my retrospective on a more serious note. I’m grateful to Kerry and Marney for standing with me in writing and publishing a public statement on behalf of Fabbaloo regarding the state of the world. We agree that in this time of hatred and divisiveness, of violence and racism, that what is needed right now is a strong stance of not remaining silent. A major part of why I chose, two years ago, to work with Fabbaloo is because of the strength of integrity I’ve always observed from this team. That’s only been reinforced through actually working as part of the team. For Fabbaloo, for the 3D printing industry, the best way forward is together, and so we do stand together with all participants, and look forward to a stronger future with a more diverse makeup. We will continue to do our part to boost more voices, to share more opportunities designed to enhance access to education and training for more communities, and to share resources and actionable takeaways to help every company reach its best potential.

As of this piece, Fabbaloo has now published 10,005 articles. We look forward to continuing to grow, to share with you, and thank you for being there with us along this ride! We couldn’t do what we do without you. Cheers to the next 10,000.