This week’s selection is “Triceratops Skull No. 21” by Javid Jooshesh.

Triceratops Skull No. 21 Story

The story of this design begins 67 millions years ago, when an unfortunate Triceratops met its fate in an unknown fashion. Over the intervening course of time, this creature’s bones were fossilized into solid rock and buried below for an eon.

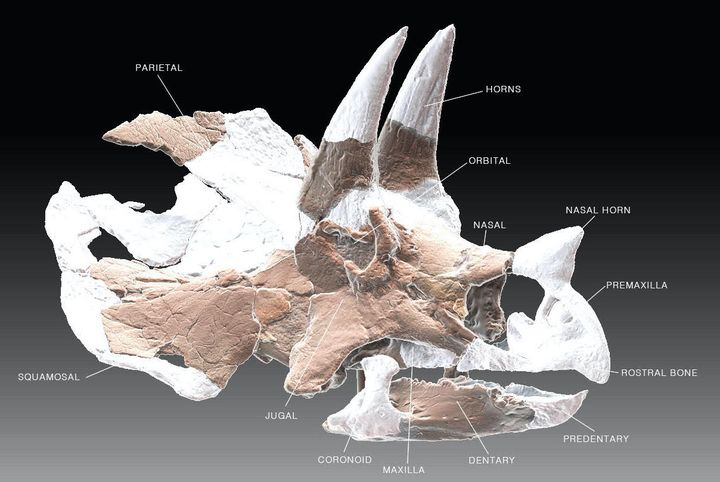

The fossilized skull was eventually discovered in Wyoming in 1884, and recovered in pieces by researchers from the Peabody Museum of Natural History. These were reconstructed into a proper skull by paleontologists thereafter.

Then the story gets strange.

The skull was traded for a collection of marine invertebrate fossils with the Delft University Geological Museum. Unfortunately, despite careful packing, the skull suffered a catastrophic drop during trans-Atlantic transport and arrived in literally hundreds of pieces.

Workers at Delft spent years reconstructing the skull to the best of their ability, and it was put on display for many years.

Recently however, it was discovered that the skull had been reconstructed incorrectly. Even worse, the folks back in the US discovered boxfuls of pieces that likely belonged to Skull No. 21. Thus a THIRD reconstruction project was commissioned, but this time using advanced 3D techniques.

Reconstructing Triceratops Using 3D

The process undertaken by the team is a fascinating example of the power of today’s 3D technology: 3D scanning, 3D modeling and 3D printing are being employed to bring Skull No. 21 back to life. Well, not exactly to “life”, but at least to a more accurate representation of the original creature.

Jooshesh is a member of a large team working on the project, which includes:

- Commissioning: Delft Science Centre, Delft University of Technology

- 3D scanning: Valentin Vanhecke and Javid Jooshesh

- Digital Reconstruction: Javid Jooshesh

- Scientific Guidance from Naturalis: Hanneke Jacobs, Martijn Guliker, Jimmy de Rooij

- 3D Printing: Niels Hunck, 3D Printing Prototypes

- Assembly: Aart Walen at the Boxtel Oertijd Museum

Jooshesh explains their approach:

“The goal was to reconstruct the skull using 3D technologies as opposed to traditional methods, as it is believed they provide more possibilities to reconstruct the skull based on scientific aspects. It was an inclusive process starting from digitizing the data using structured light 3D scanners, 3D modeling the missing parts based on scientific guidance, and 3D printing the missing elements that fits like a puzzle in the end.”

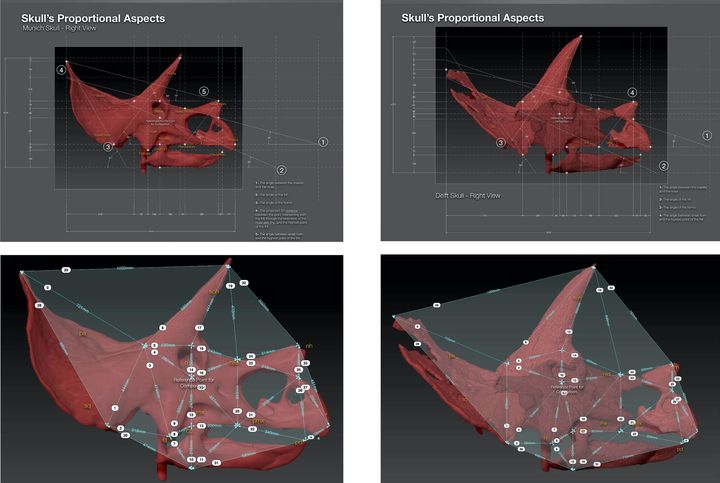

One of the key strategies was to leverage two other existing Triceratops skulls by comparing their aspect ratios to No. 21. This allowed the team to create a more accurate 3D model and avoided the mistakes of past reconstructions.

You’re probably wondering how they managed to recreate the missing parts. This was done by Jooshesh, who, using Pixologic ZBrush, painstakingly designed pieces to fill the gaps in the Skull.

Here’s the really interesting part: to texture the surfaces of these new parts, he obtained textures from the two other skulls and used them to model the new parts. This ensured they have an appropriate texture that mostly matches the rest of the skull.

The 3D scanning was done using Artec Eva and Space Spider devices, which I know can capture these objects in very high resolution. For 3D printing, the team used BigBuilder Extreme 1000 Pro and Extreme 1500 Pro machines, which are easily large enough to 3D print any part required by the project. Some parts are fairly large, as the entire skull is about 2m in length.

Once all the parts are designed and produced, there is the matter of assembling it into a complete skull, which is currently underway.

One interesting decision made by the team is to leave the 3D printed PLA parts in their original colors (grey) so that they provide contrast with the original fossil material in the final assembly. This should prove enlightening to museum visitors, who will see with their own eyes how 3D printing technology can literally fill the gaps.

The project is set to complete later in August, when Triceratops Skull No. 21 will once again be held high in its original form, the same as it was 67 million years ago.

Via Yale and Javid Jooshesh