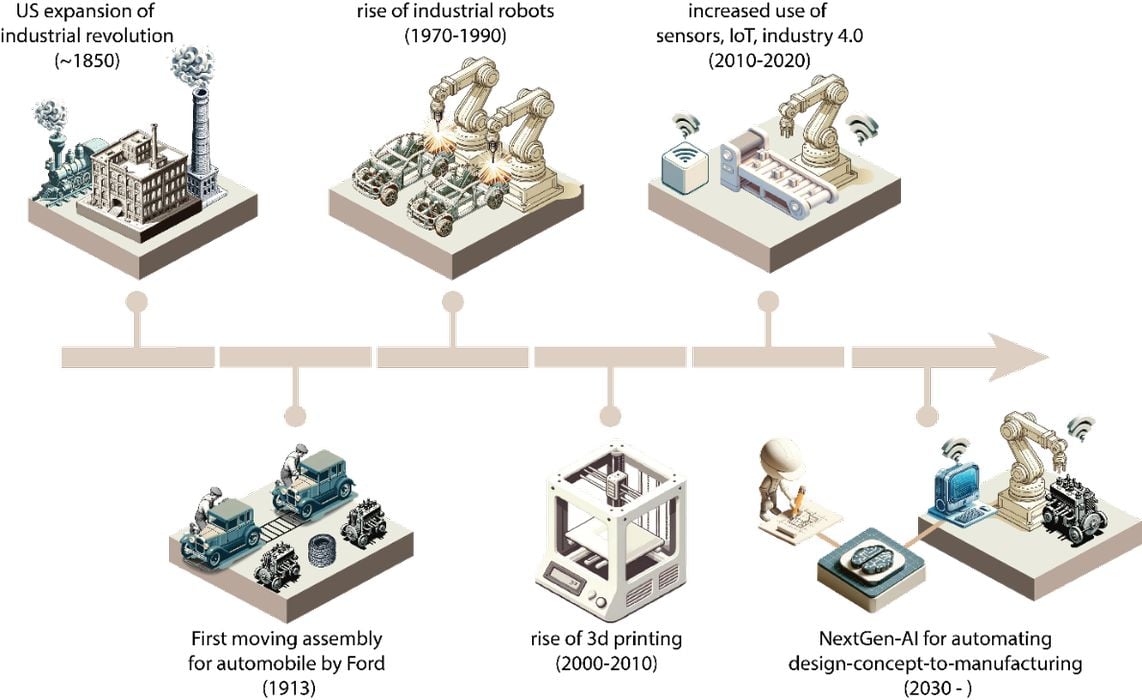

MIT has released a very interesting paper analyzing the potential of using AI to generate part designs for industry.

There has been an explosion of AI generative tools over the past year and a half. While the public is mostly aware of text and image generators, there are plenty of AI tools to produce other digital data, including music, video and, you guessed it, 3D models.

We’ve been trying several of these tools, and while they are exciting to use, the output is generally not really suitable for industry use. At least not yet. The theory is that eventually these tools might advance sufficiently to take on the role of CAD designer.

But could they? That was the subject of the paper, “From Automation to Augmentation: Redefining Engineering Design and Manufacturing in the Age of NextGen-AI” recently published by MIT.

What did they find? Initially, they interviewed a number of those involved in manufacturing to see where benefits could be found. The list of benefits included:

- Reducing the incidence of costly late-stage design changes when scaling production

- Providing information to designers and engineers, including identifying suitable design spaces and material formulations and incorporating consumer preferences

- Improving test data interpretation to enable rapid validation and qualification

- Democratizing workers’ access and usage of data to enable real-time insights and process adjustment

- Empowering less-skilled workers to be more productive and do more-expert work

However, they also found that the current leading LLM AI tools, such as Claude and ChatGPT, are not today able to meet those goals. Why? They provide a list:

- Inability to provide robust, reliable, and replicable output

- Lack of relevant domain knowledge

- Unawareness of industry-standards requirements for product quality

- Failure to integrate seamlessly with existing workflow

- Inability to simultaneously interpret data from different sources and formats

Does that mean we can never achieve true “text-to-CAD”? By no means! The researchers suggest a way to develop new AI frameworks that could overcome these deficiencies and possibly achieve the goal of true text-to-CAD.

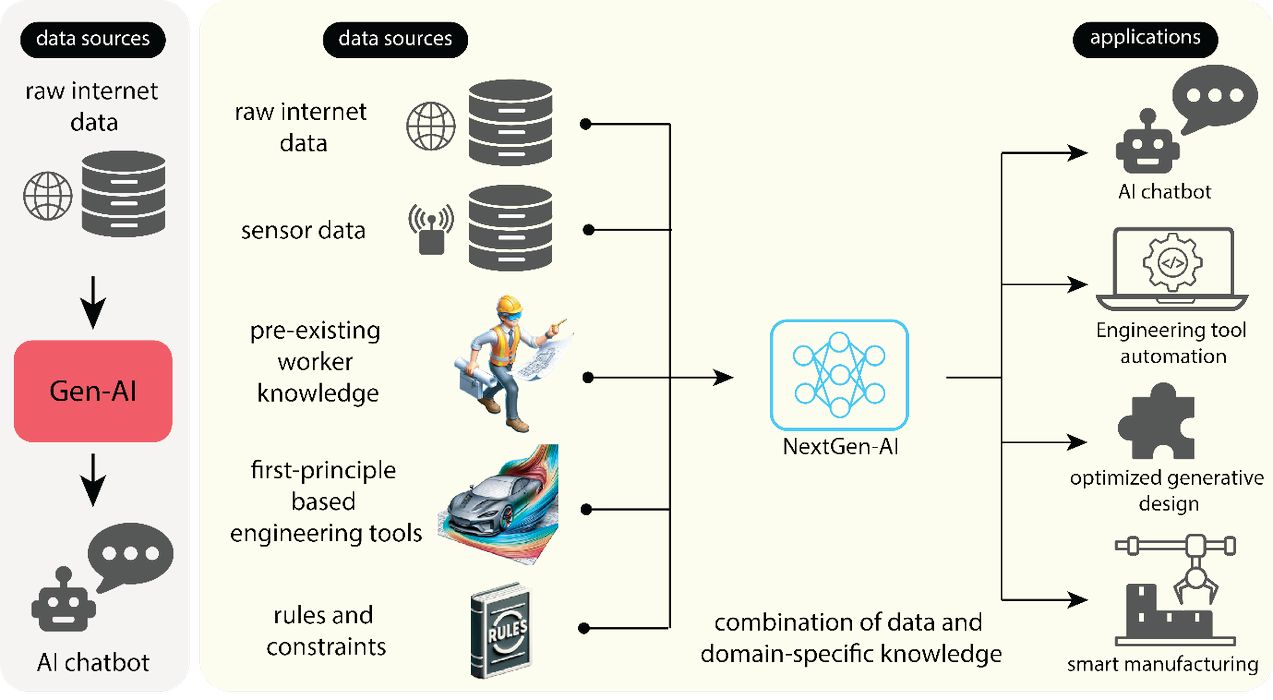

They suggest:

- Provide better information about engineering tools, repositories, search methods, and other resources to augment the creative process of design

- Integrate adherence to first principles when solving engineering problems

- Leverage employees’ experiential knowledge to improve training and performance

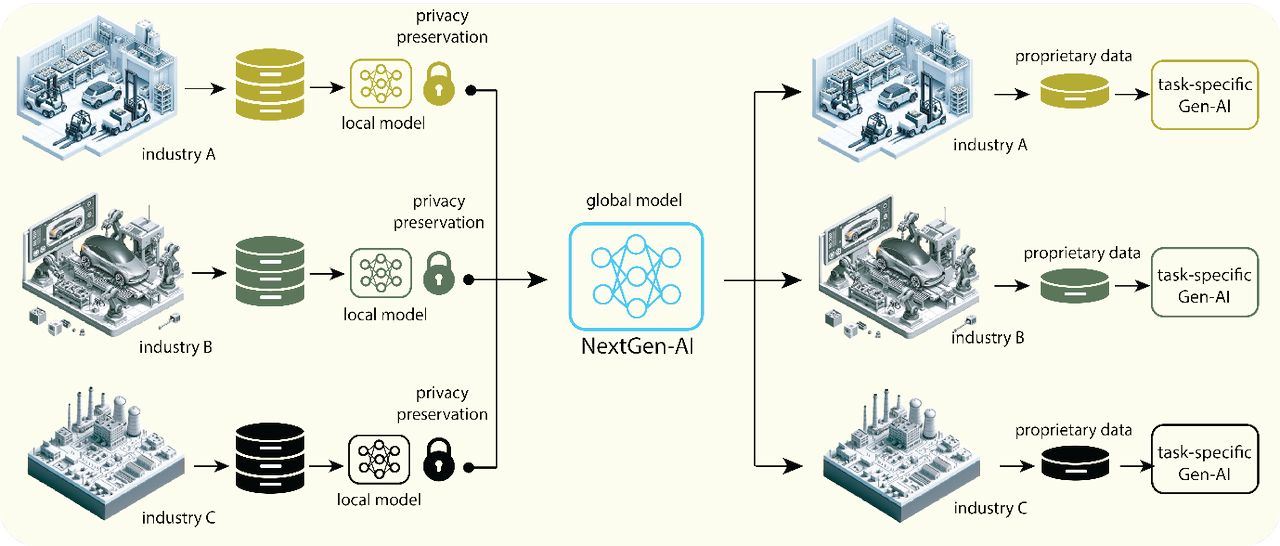

- Empower workers to perform new and more-expert productive tasks rather than pursue static automation of workers’ current functions

- Create a collaborative and secure data ecosystem to train foundation models

- Ensure that new tools are safe and effective

In short, focus the AI tools on the domain in question.

However, the devil is in the data, and they further recommend that at this early stage priority should be made for data collection. That would include real time data, data governance, safety concerns and more.

They provide detailed analysis of multiple manufacturing scenarios and have developed a “strategic framework” for developing this technology in the near future.

Their conclusion:

”Our discussions with manufacturing experts and industry leaders motivate our concern that the current capabilities of Gen-AI tools are not sufficient to deliver significant productivity upsides for manufacturing and design. However, we believe that it is possible to overcome many of these challenges by considering domain-specific challenges while developing these powerful models.”

Via MIT