At this year’s 3D Printshow in London the most important item seen, in our opinion, was the launch of ColorFabb’s Amphora line of plastic filament.

You might ask the question, is it ABS or PLA-based. The answer, surprisingly, is neither. It’s an entirely new polymer, never previously used for 3D printing. In fact, it’s never been used EVER.

Amphora has been newly developed specifically for filament-based 3D printing applications by the American firm Eastman Chemical Company. As far as we know, this has NEVER happened before. Plastics used for 3D printing were in fact, leftover plastics, designed for other purposes that had nothing to do with 3D printing.

Now, however, there are sufficient 3D printers in the world to justify the development of new plastics that match the needs for improved 3D printed filament.

Imagine if you were granted a wish to magically develop a new plastic filament. What properties would you include in it? Would you make it shiny? Bendable? Heat resistant? Dishwasher safe? That’s the challenge posed by ColorFabb to Eastman last year. Eastman chemists took up this challenge and created a checklist of required properties.

And then they made a polymer that has them.

Ok, let’s get directly to the juicy facts about Amphora:

- It produces very little to no odor during printing, avoiding the same issue experienced when printing ABS

- Far fewer unhealthy nanoparticles become airborne during Amphora printing, unlike ABS plastic

- Amphora is a very strong material, avoiding the fragility of PLA plastic

- Finer details are possible due to the strength of the material

- Amphora has a higher melting point than PLA, meaning you might be able to leave an Amphora print on your car dashboard and expect to not melt

- Layers bond together much better, meaning prints are stronger and surface finish is improved

- The material has very strong chemical resistance; few common substances will affect it

- It’s approved by the US Food and Drug Administration for “food contact” applications

Although the material is food contact-safe, that doesn’t mean a 3D printed Amphora cup is literally foodsafe, as gaps in the layering can physically harbor bacteria. That said, if a new process used Amphora to produce a perfectly sealed surface, it could indeed be a foodsafe object.

We’re particularly interested in the safety characteristics, as personal 3D printers are increasingly installed in people’s homes – even their bedrooms. We cannot imagine a world where ABS fumes are breathed by sleepers for hours every night. Amphora should change all that. In fact, Eastman’s expert says there are no toxic styrene elements within Amphora and that the amount of nanoparticles is “way lower” than when printing ABS.

We asked Eastman’s representative about methods for smoothing Amphora, such as is done for ABS with Acetone. Apparently there is no common substance that can smooth Amphora – it’s simply too resistant to chemicals. That’s the only downside we could find with the new material.

If you’re skeptical of Amphora’s physical properties, just watch this video, where ColorFabb’s Sander Strijbos crushes an Amphora print to an impossible degree – and watch it snap back into place! Wouldn’t you like your prints to act like that?

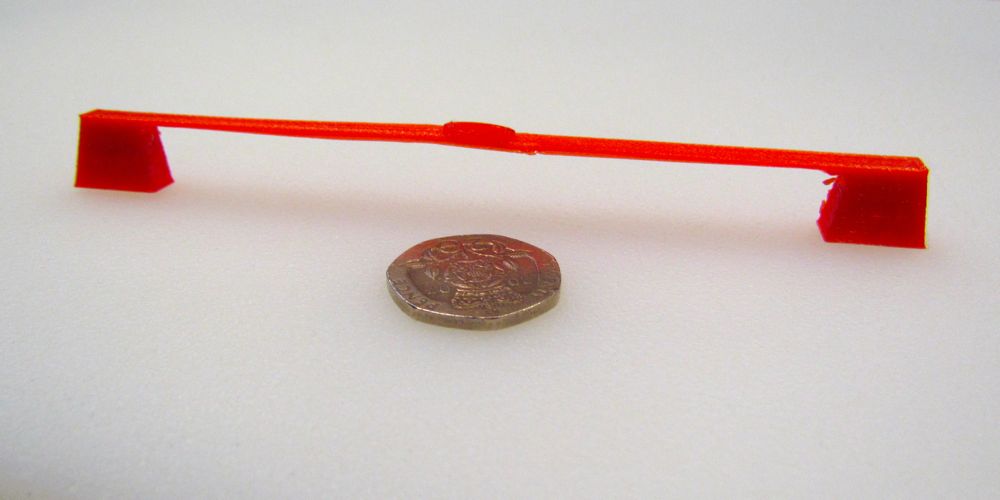

Here is an example of the strength of Amphora. This is a rather long bridge easily built with Amphora. At the time of this writing, they were attempting to increase the gap by another 5cm. Incredible!

Amphora seems like a miracle material made just for 3D printing. That’s because IT IS made specifically for 3D printing. For now, ColorFabb will be marketing a line of Amphora products, likely eventually abandoning their existing plastic products. The new Amphora material is officially called “XT-COPOLYESTER” made from “Amphora 3D™ Polymer” by ColorFabb. Other filament manufacturers may eventually adopt Amphora, too, but there are none so far.

Our spies tell us that the new material is actually just the first of MANY new plastics that will be specifically designed for 3D printing. We’re expecting to see several new variations emerge over the next few months, including: a heat resistant version; a dissolvable support material; and much more.

Best of all, the implication of this new material implies that 3D printing has reached the stage where it deserves its own plastics. This is a huge milestone for the personal 3D printing industry. Congratulations, we made it!

Via ColorFabb