A unique plasma nozzle could revolutionize FFF 3D printing.

Hilgenberg Ceramics worked with a “well-known German institute” to create this unusual ceramic nozzle, made of high-purity Al2O3 material.

The problem they’re trying to overcome is layer adhesion: in FFF 3D printing, new layers are deposited on the previous layer that’s already cooled somewhat. That cooling prevents full molecular bonding between layers, making that the weak spot in every FFF print. This results in prints that are inevitably isotropic in strength.

There have been attempts to overcome this issue in the past, with perhaps the most notable being Essentium’s electric filament. The idea was to run a current through the filament to the print surface, keeping the material hot as more layers were deposited in a process they called “thermal welding”. However, this approach didn’t seem to catch on.

The new ceramic plasma approach seems more practical and possibly easy to implement.

They realized that an application of plasma could increase layer adhesion. Apparently this approach has been commonly used for decades in other industrial applications, such as packaging. However, it has never been applied to 3D printing previously.

How does it work? It’s actually quite simple.

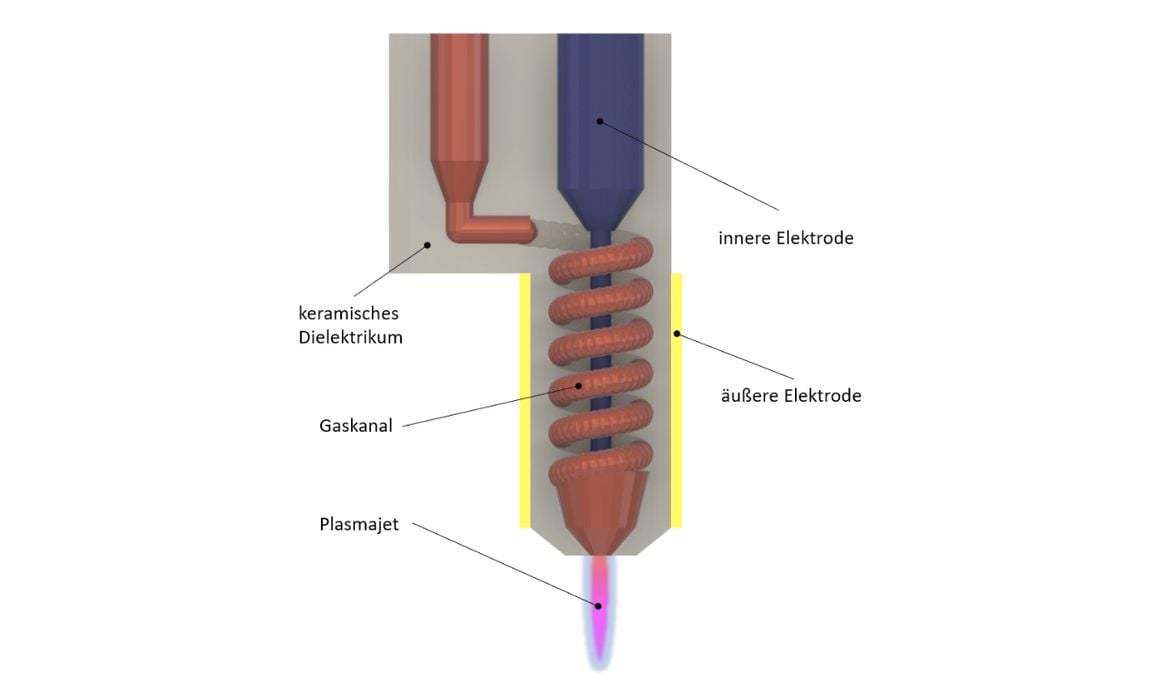

A specially designed nozzle is attached to the toolhead. This nozzle is able to generate a small plasma flow. When a layer is complete, the toolhead sweeps across the prior layer, treating it with plasma. This “activates” molecules in the deposited layer to make them more adhesive.

This results in layers that are far more properly bonded, and thus anisotropic parts can be produced.

The nozzle is pretty sophisticated, however. It’s made from ceramic and coated with copper, with an interior electrode. Air passing through becomes a plasma jet, which flows out the nozzle onto the deposited polymer.

The researchers had to make the nozzle quite small in order for it to fit with typical FFF 3D printers. The dimensions of the nozzle are only 40 x 20 x 20 mm, quite tiny. It turned out the complex design was such that it had to be 3D printed, ironically.

The nozzle is also made primarily of a ceramic, Al2O3. This is because plastic nozzles tended to accumulate graphite deposits, and lose their dielectric properties. However, the ceramic nozzle is able to operate for far longer periods without issue.

The team found that in addition to adhesion, the plasma nozzle could also etch surfaces, sterilize objects, clean off surface layers and more.

I have a strong suspicion this nozzle design will (if it isn’t already) be patented, and eventually be commercialized. It seems to me that the cost of this method is sufficiently low that it could possibly be included on future desktop FFF 3D printers, making them far more powerful.

Would you buy a plasma-powered FFF 3D printer?

Via Hilgenberg Ceramics (German) (Hat tip to Benjamin)

You’ve got isotropic and anisotropic mixed up.