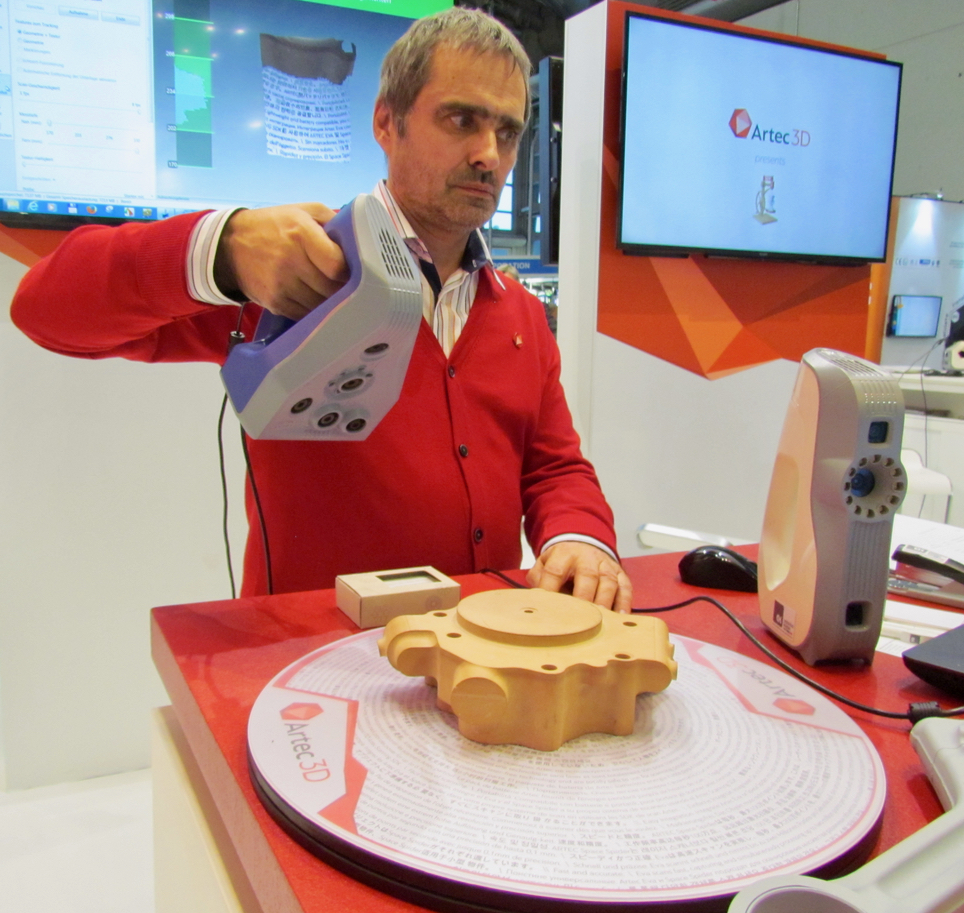

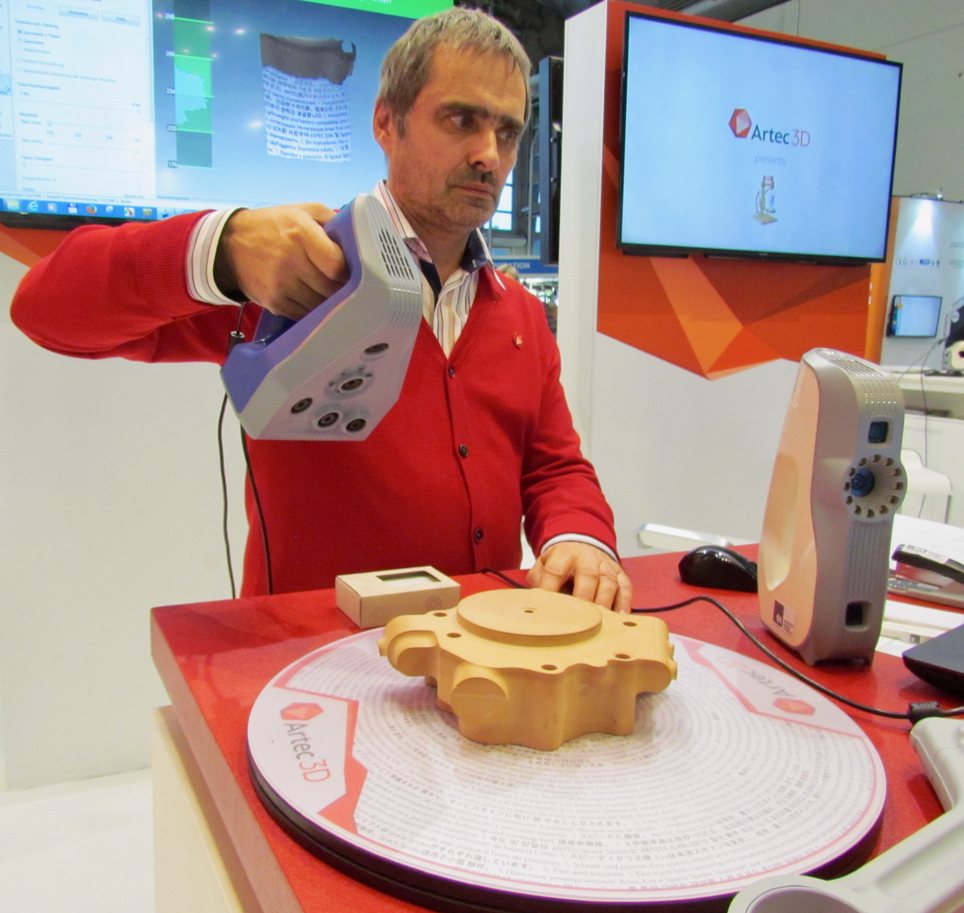

Artec 3D is a Luxembourg-based company producing handheld 3D scanners, and they have two units that seem to cover most of the requirements.

If you’ve ever used a handheld 3D scanner, the is a constant tradeoff: size versus resolution.

In some cases you may require extreme detail for a scanned object. Perhaps it is of a critical shape and you must capture the details in extreme accuracy to succeed.

On the other hand, you might have a relatively large (or extremely large) object that must be scanned and resolution is a lesser factor.

These two requirements are essentially mutually exclusive; it would be challenging to create a device that can do both very well. Instead, Artec 3D has two different devices that each perform different types of 3D scans.

The Eva 3D scanner uses a structured light approach to capture scans and thus does not require the use of reflective targets to be placed on the scanned object.

How large can you scan with the Eva? We were told an entire helicopter was 3D scanned by one of Artec 3D’s customers in Turkey. The Eva is not limited by the size of the scanned object and can capture at the rate of 15 fps.

The Eva Lite is available for around USD$9,300, but does not capture colors or textures, so it is a relatively inexpensive way to get into professional 3D scanning.

On the other hand, their Spider model, which also uses a structured light / no targets approach, is designed for capturing fine details on a smaller volume. It’s available for around USD$20,000.

You should know that 3D scanning is as much about the hardware as it is about the software. Artec 3D has taken considerable steps to make the software process as simple as possible.

Their TechStudio software makes capturing and post-processing of 3D scans very straightforward. In fact, we were told version 11 has 100x faster registration, transforming what was previously a 5-6 hour job into only 3-4 minutes. The software can do things like automatically remove the “floor” or object on which the scanned object is sitting. This is a commonly encountered nuisance in 3D scanning systems where the scan also captures the floor. Not so with Artec 3D’s system.

However, Artec 3D’s software cannot do everything you might require when dealing with a 3D scan, so they provide an easy click through button to transfer the scan to other software like 3D Systems’ GeoMagic X. They also provide a Solidworks plug-in.

If you’re starting out with professional 3D scanning, Artec 3D offers some good options.

Via Artec 3D