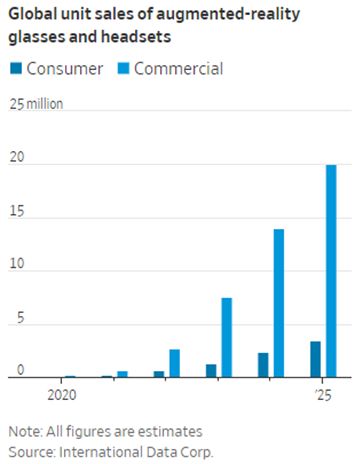

The April 7th, 2021 edition of the Wall Street Journal contained an article indicating that augmented reality (AR) technology is now hitting its stride with a prediction of large commercial sales.

This follows the recent announcement by Microsoft that the U.S Army will be purchasing up to $22 billion in AR-related products with the intention of using the technology in part to replace night vision products. The lineup of leading companies focusing on the AR market demonstrates how this technology is clearly considered a major business opportunity. In addition to Microsoft, some of the leading companies focusing on AR include Facebook, Apple, Niantic (Pokémon Go), Qualcomm, Alphabet/Google, and Upskill, the developer of software for AR. Concurrently, the 3D printing community is expecting 3D printers to steadily evolve from mainly being a design tool to a means of production. This is particularly the case for metal 3D printing. The 3D printing production environment is being further supported by Industry 4.0 initiatives that integrate 3D printing, CNC machine tools, robots, and digitization.

Augmented reality systems enable the user to access computer research and data everywhere the user goes without completely removing them from the world around them. Some examples of programs that can be viewed simultaneously with the real-world directions on a map, texts, or food recipes. This contrasts with virtual reality (VR), a fully immersive experience where the user is completely blocked off from the outside world. VR is currently widely available to consumers today.

The traditional 3D printing design activity has typically operated in a conducive office environment located within or near engineering, CAD, and design departments that are physically separated from the production plant floor. In the office location, computer access is prevalent, and research and data access can be comfortably viewed at a desktop.

The manufacturing production plant floor space is typically much more chaotic and intense. Plant industrial (IEs) and manufacturing engineers (MEs) need to conduct research concerning materials, production scheduling, bills of materials (BOMs), data and processes on a real-time basis in a production environment. Augmented reality headsets bring all the necessary information immediately right to the production manufacturing user. Augmented reality is also excellent for training and can be used to provide hands-on training on the plant floor.

The Research & Development Tax Credit

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

New promising technology always takes longer than anticipated to hit its stride, and improvements often happen in spurts rather than progressing linearly. AR innovation appears to make meaningful improvements just when 3D printing can benefit from these improvements as it advances from the prototype/design phase to the higher volume production levels.