Researchers have developed an unusual method of producing a battery, one that could be integrated into 3D printers.

Batteries are a common item, but they are all constructed in more or less the same manner: a cathode is separated by an electrolyte from the anode. With this structure electrons can flow and be stored.

Most modern battery designs are cylindrical. In order to produce this battery geometry, the “jelly roll” process is used: sheets of anode, cathode and electrolyte are spun around a rotor, rolling up into a battery shape. If you were to disassemble a battery (and really, don’t) you’d see a spiral of these sheets together. This forms a large surface area on which the electrical activity can occur.

Now there’s another way to produce a battery with an equivalently huge surface area: a thermally drawn rechargeable battery fiber.

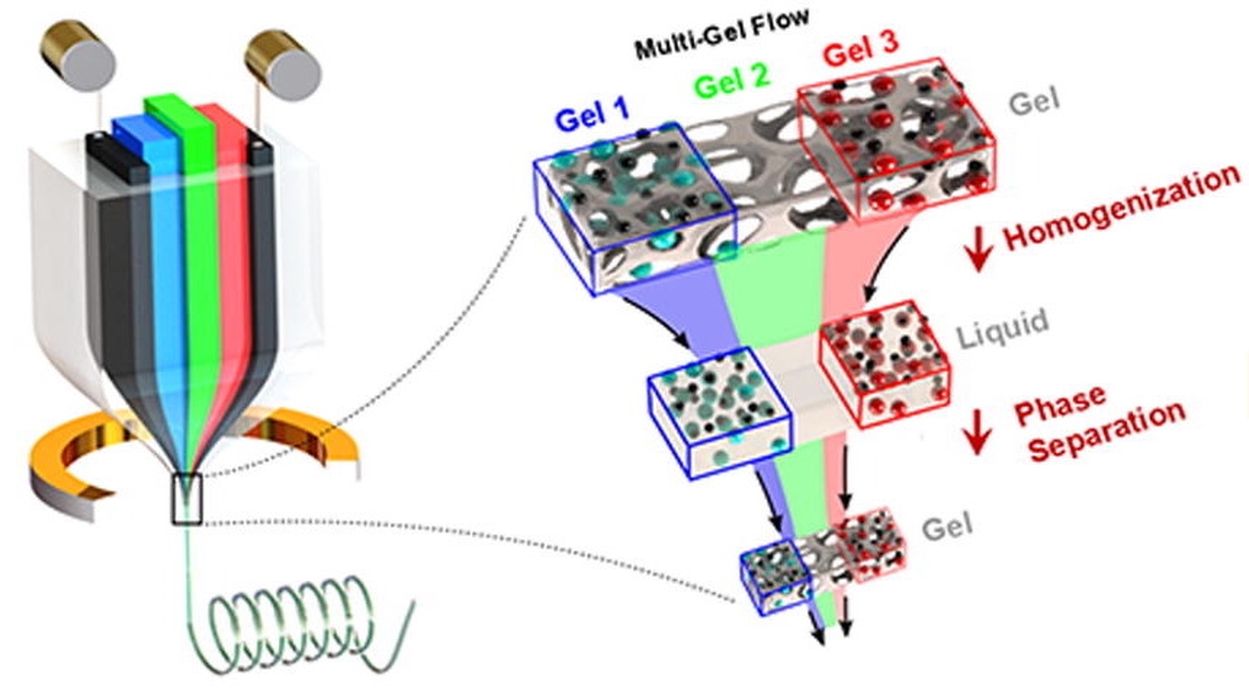

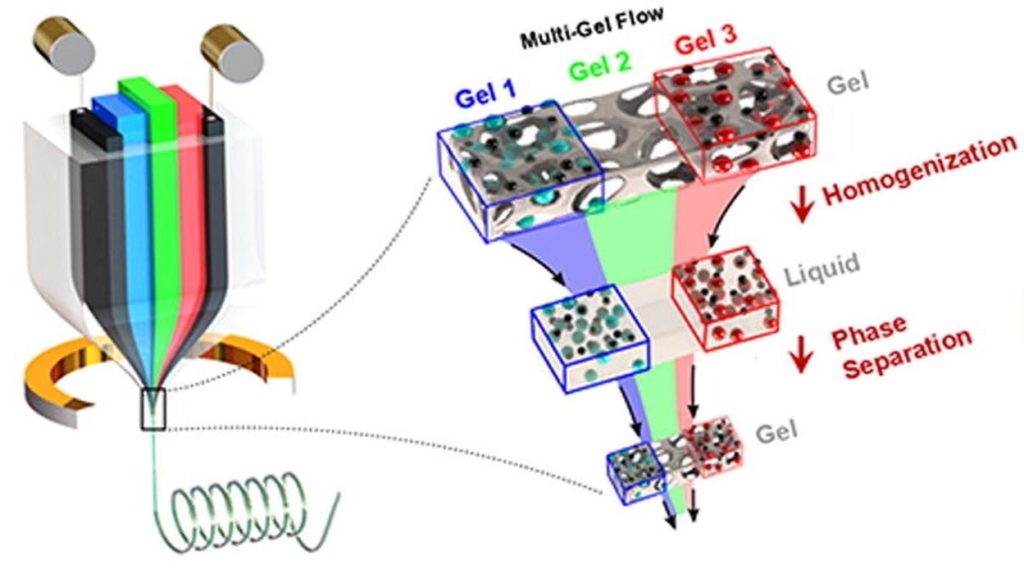

As shown in the diagram at top, the idea is to squirt out a composite fiber with the representative components aligned together. The electrical activity takes place in the same way, except that instead of being rolled up into a cylindrical shape, the electrical surface area appears all along the fiber.

Apparently these “battery fibers” can be as long as you want, and their electrical properties can vary by length: more length equals more storage capacity, just like a battery cylinder with more diameter can store more energy.

This type of battery could be exceptionally useful for modern consumer devices that are quite small and have unusual shapes for battery installation. The battery fiber could be simply deployed into the available space, adapting to volume conditions.

The battery fibers are said to be quite durable and robust. The researchers explain:

“The fiber battery satisfies the requirements of portable electronics systems as it is machine washable, flexible, usable underwater, and fire/rupture-safe. We have demonstrated the powering of a submarine drone, LiFi fabric, and flying drone communication through different rechargeable fiber battery schemes, which paves the way for the emergence of the pervasive battery-powered electronics.”

3D Printed Battery Fiber

One very intriguing possibility for this technology is in 3D printing.

Readers may recall there are several 3D printers on the market that can 3D print continuous carbon fiber. These long fibers are extremely strong, and the ability to embed them in an otherwise weak polymer print can provide tremendous additional mechanical strength.

The 3D printers that do so basically have a spool of the carbon fiber and a special toolhead that lays out this fiber as required. It’s cut when needed as the print job proceeds.

Now imagine something a bit different. Instead of the carbon fiber toolhead, we have the battery toolhead, which can extrude the battery fiber in the same way as the researchers have accomplished.

This “battery printer” could use multiple toolheads to deposit both polymer and battery into a print. The battery fiber could even take up space as infill in the print, and possibly provide very significant energy storage.

There are obviously challenges here, not the least of which is maintaining a continuous battery fiber between layers. It may be that the battery fiber has to be segmented where discontiguous portions of a layer occur, and this would require a means to electrically reconnect the segments.

Nevertheless, this is a very interesting development that could at some point in the future make its way into 3D printers.

Via ScienceDirect