![[Source: Gizmodo ]](https://fabbaloo.com/wp-content/uploads/2020/05/Drone1_img_5eb09524f25e6.png)

Cameron Torti and Charles Goulding of R&D Tax Savers examine 3D printing’s impact on drones.

Wing Aviation LLC, a subsidiary of Alphabet Inc., became the first drone manufacturer to get FAA approval earlier this year. Many companies had only received waivers from the FAA to demonstrate flights and make short distance deliveries. Urban areas are also troublesome in the eyes of regulators. Approval for Wing Aviation only came after issues regarding what regulations should apply for drones were established; this resolution provides a pathway for other companies. Additionally, rules published in January by Transport Canada for flying drones are now in effect. The American and Canadian approval signifies that commercial drone operations are starting to become a reality, and big tech companies have responded. Recently, Uber has announced performance trails for its food delivery service and Amazon says it will deliver packages by drone “within months”.

Growing Market

Drones of all kinds have been on the rise across the majority of industries, with government accounting for 70% of market share followed by consumer next with 17%. By the end of 2018, the FAA announced that over one million consumer drones have been registered. In addition to an increase in military drones, the FBI and the U.S. Department of Homeland Security have also been adopting drone use. Furthermore, disaster management, firefighting, and agriculture add to the growing list of applications contributing to the growth of the drone market which Goldman Sachs expects will have expanded by $100 billion between 2016 and 2020. By the end of the year, drone registrations are predicted to reach close to 2.4 million for consumer and commercial drones.

![[Source: Business Insider ]](https://fabbaloo.com/wp-content/uploads/2020/05/Drone2_img_5eb09525902d4.png)

3D Printing Drone Components

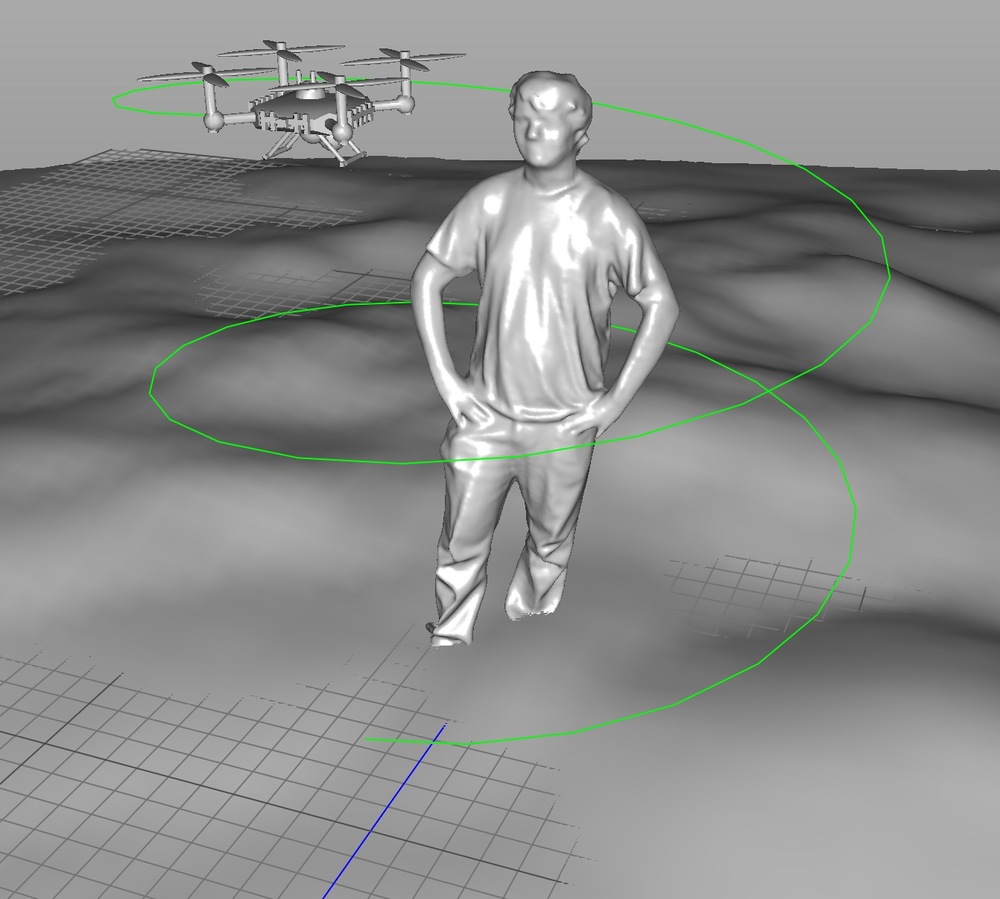

Expanding parallel to the drone industry, 3D printing has already been employed to expedite prototyping. A team of researchers at Yale are drawing inspiration from animals to better develop landing gear using 3D printing. One of the biggest challenges for drones, particularly drones in the commercial sector, is finding an ideal landing spot. Traditionally, an ideal landing spot was believed to be flat and open. However, these researchers have found ways that drones can perch like birds. The challenge is being able to develop landing gear that can perch on variety of structures and still be able to land flat. Developing and testing many new designs can be costly and 3D proves to be an invaluable tool in the process, cutting costs dramatically. The advantages of perching includes a broader range of landing spots and preserving precious energy by allowing the drones to partially or wholly power down, increasing flight time and load capacity.

![Drone perching [Source: Popular Mechanics ]](https://fabbaloo.com/wp-content/uploads/2020/05/Drone3_img_5eb09525d8af1.png)

Turning to military applications, an Australian manufacturing company named Titomic has created the largest titanium 3D printed drone. The drone was manufactured in their Melbourne facility which houses the largest and fastest 3D printer in the world. Employing patented 3D printing technology, Titomic uses a cold spray method to fuse metal particles. The titanium boasts a superior strength-to-weight ratio compared to other metals making the drone strong and durable against ballistics, in addition to being lightweight.

![Titomic's Titanium drone [Source: DroneBelow.com ]](https://fabbaloo.com/wp-content/uploads/2020/05/Drone4_img_5eb09526361d2.png)

Aside from speeding up development and making it easier to replace parts, 3D printing presents several advantages specific to drone manufacturing. It allows denser material to be printed in different areas such as landing gear while also reducing weight in the rest of the frame. Aerodynamic designs are also easier to print than they are to mold. 3D printing download files for replacement parts are widely accessible online for drone hobbyists who own 3D printers.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayer’s business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and for the first time, startup businesses can obtain up to $250,000 per year in payroll taxes and cash rebates.

Conclusion

It appears to now be confirmed that drones are not just here to stay, but to grow exponentially in the coming years. 3D printing’s potential has proven to be the most important catalyst for this explosion do to its extreme versatility and utility.