Filamentum introduced an unusual new 3D printer filament, Fluorodur.

The new material exhibits a number of unusual properties, including incredible heat resistance. These properties may be of interest to those 3D printing parts for specific application environments.

The material is polyvinylidene fluoride (PVDF), hence the product’s name. The PVDF resin is sourced from chemical provider Arkema, who provide their Kynar PVDF to Filamentum.

There are plenty of unusual 3D printing materials now available, so what makes Fluorodur different?

The main feature is the huge thermal resistance. This material has a glass transition temperature of up to 150C, far greater than many commonly available 3D print materials. That alone will make it attractive for use in high-temperature applications.

Fluorodur Benefits

But there’s more to this new material. As I perused its specifications, I noted several other beneficial properties:

Fluorodur has relatively low moisture absorption, unlike certain other high-temperature materials. This will make it easier to store and use without compromising print quality.

The material also has very good UV resistance, meaning it would be quite usable for outdoor applications. Combined with the high heat resistance and its strong chemical resistance, this opens up many application possibilities for weather resistant parts.

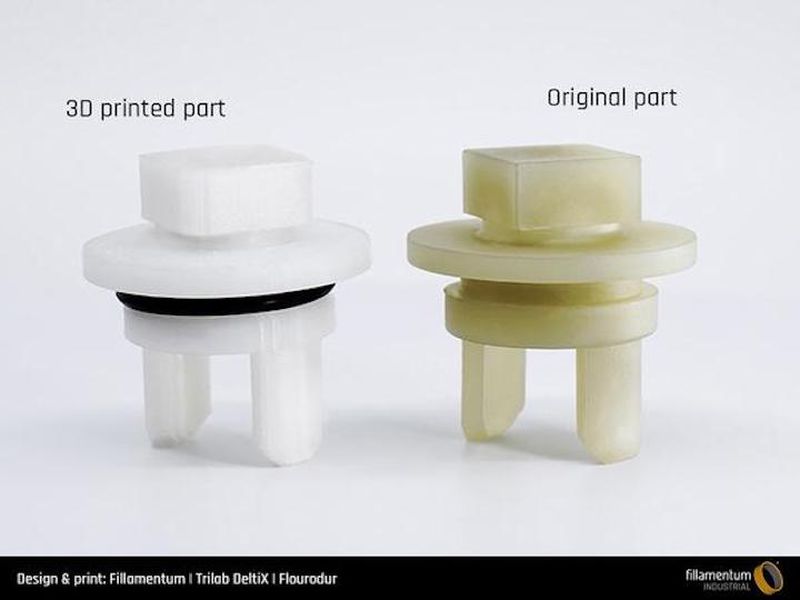

Fluorodur is a very rigid material, making it ideal for use in applications where precise edges and dimensional accuracy are required. In this image you can see how a Fluorodur part compares with an original part.

Finally, Fluorodur has one more very useful property: it’s self-extinguishing, something few materials exhibit. Filamentum explains:

“The presence of halogen atoms in the polymer chains (chlorine, fluor, bromine, iodine) predetermines self-extinguishing. In the case of fire, the material starts burning, but when the source of fire moves away, it extinguishes after a short time, so the fire does not spread. It complies with the requirements of V-0 class (but always, the final product must be tested under specific conditions).”

Fluorodur Challenges

While those benefits are notable, there are some drawbacks with Fluorodur, as there are with all 3D printer filaments.

Filamentum rates the material as difficult to print, and this is likely due to its very high tendency to warp. They rate it as higher than PP, PC/ABS and nylon, and that certainly indicates you’re in for an adventure when 3D printing this filament.

The material will most certainly require 3D printing in an enclosed and heated chamber to avoid or at least minimize warping. This type of 3D printer tends to be on the pricey side, so Fluorodur is not a material anyone would be able to 3D print.

Another interesting property of Fluorodur I observed was its density: 1.79g/cc. This is substantially higher than Filamentum’s PP (0.96g/cc) or their PC/ABS (1.07g/cc).

What this density means is that if you were to purchase a kilo of Fluorodur, you’d find yourself with only 60% of the volume of a 1kg spool of PC/ABS, and about half of the volume of the equivalent weight of PP.

In other words, you effectively have to double the price for a given part if you’re switching from those materials to Fluorodur.

Using Fluorodur

Like most 3D printer filaments, selecting Fluorodur is a matter of matching application requirements to the material. In some cases Fluorodur will make sense, while in others some of its characteristics might disqualify it from use.

The important thing is that there is now another tool in the toolbox to consider using when designing a 3D printed application. Fluorodur’s availability will certain enable new applications.

Via Filamentum (Hat tip to Benjamin)