I’m reading a newsletter from Diabase Engineering and had a thought about how 3D printing will play out over the long term.

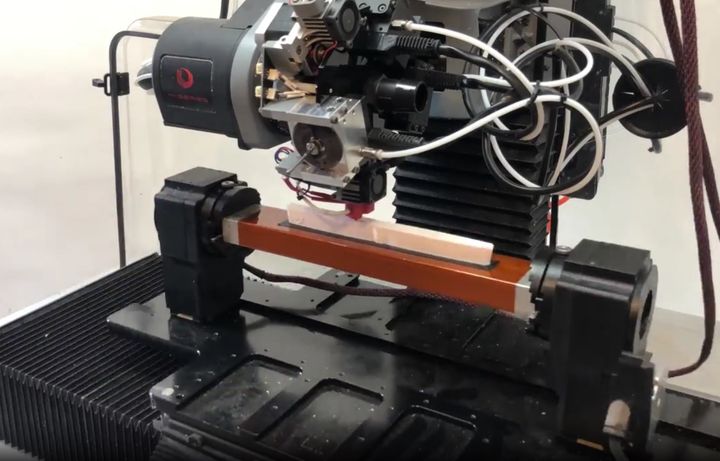

If you’re not familiar with Diabase Engineering, they are a curious mix of 3D printing and machining technologies. They began by producing the “Flexion” extruder that is capable of easily 3D printing flexible filaments, but then moved on to develop a device of their own. The H-Series uses not only the Flexion extruder, but also make use of a powerful CNC milling toolhead.

In the newsletter, they described the role of a machinist:

“The term ‘machinist’ may conjure up a stereotypical image of an older character in an oil-stained shop apron puttering away with manual tools. This is a flawed picture. The term is more akin to the word ‘technologist.’ It should evoke an individual that has a fluency in the operating principles of machines and who can efficiently make use of them to produce a desired output. It is our view that every engineer should also be a machinist in this broader sense.”

This is indeed true; machinists operating CNC machines must have a great deal of technical knowledge to successfully execute jobs on the equipment, as materials and tools can vary considerably.

However, Diabase Engineering also says:

“Meanwhile, a generation of traditional machinists have left the field, taking with them their set of skills and tools. This flux of capabilities has led to an inversion of the status of additive manufacturing versus machining in the typical technology company and the typical classroom. There are multiple problems with this situation, not the least of which is that 3D printing is a limited process.”

I hadn’t thought of the situation in this way, but they are correct. As time passes, those who are highly skilled in machining will gradually retire, and they will be replaced by younger folks who are increasingly skilled in 3D printing and related technologies.

After all, it’s been nearly 40 years since 3D printing was introduced, and over a decade since it hit the public eye. In that time schools have changed their curriculums to add more 3D content. The availability of inexpensive desktop 3D printers has allowed schools to place them in classrooms where, for the first time, most students have been able to use them directly.

This creates a different kind of student, one who is familiar with the technology to some degree, but more importantly no longer views it as a “outside” technology.

In a workshop filled with machinists, I suspect most of the time the choice of technology would be “machining”. But in a workshop filled with people who understand both, the choice would be more diverse.

In other words, there should be a very gradual increase in the use of 3D printing, not only because of advances in materials, machine capabilities and software tools, but also because the nature, training and attitudes of the people using the equipment has evolved.

I always expected this effect to occur, but it’s devilishly hard to see because it is so slow moving. It’s a situation where suddenly we realize that everyone we work with is 3D print-capable.

Maybe today is that day.