A contest on Hackaday has resulted in a design that is somewhat similar to Stratasys’ new continuous demonstrator concept.

Readers of this blog may recall Stratasys’ big announcement at RAPID 2017, where they displayed another “demonstrator” machine. This one was capable of 3D printing continuously through a combination of two approaches: parallel printing and automated print removal.

The latter is what concerns this post.

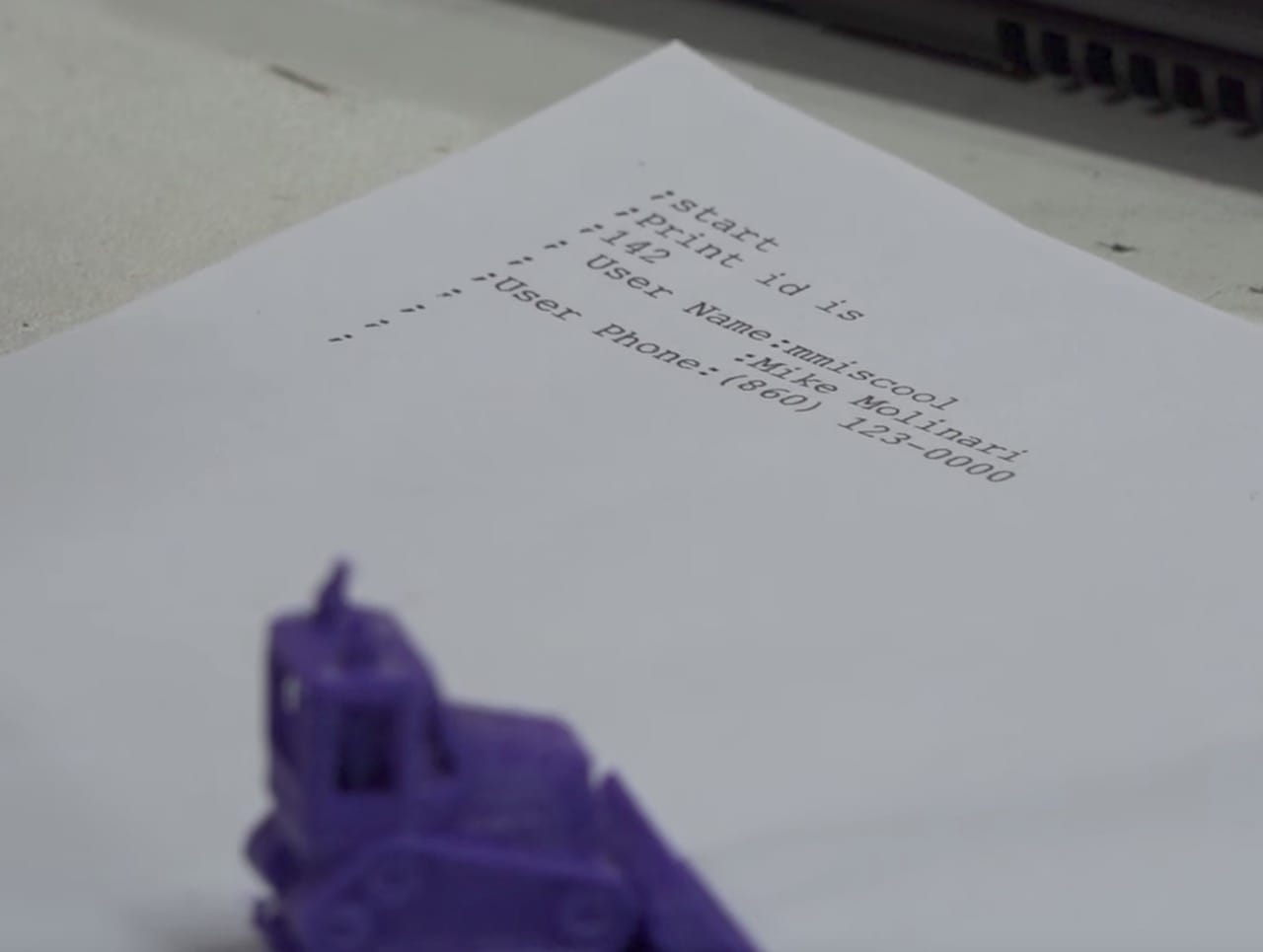

Evidently hacker Mike Molinari designed an ad-hoc system that can do this, and it’s unlike any other auto-print-handling system I’ve seen previously.

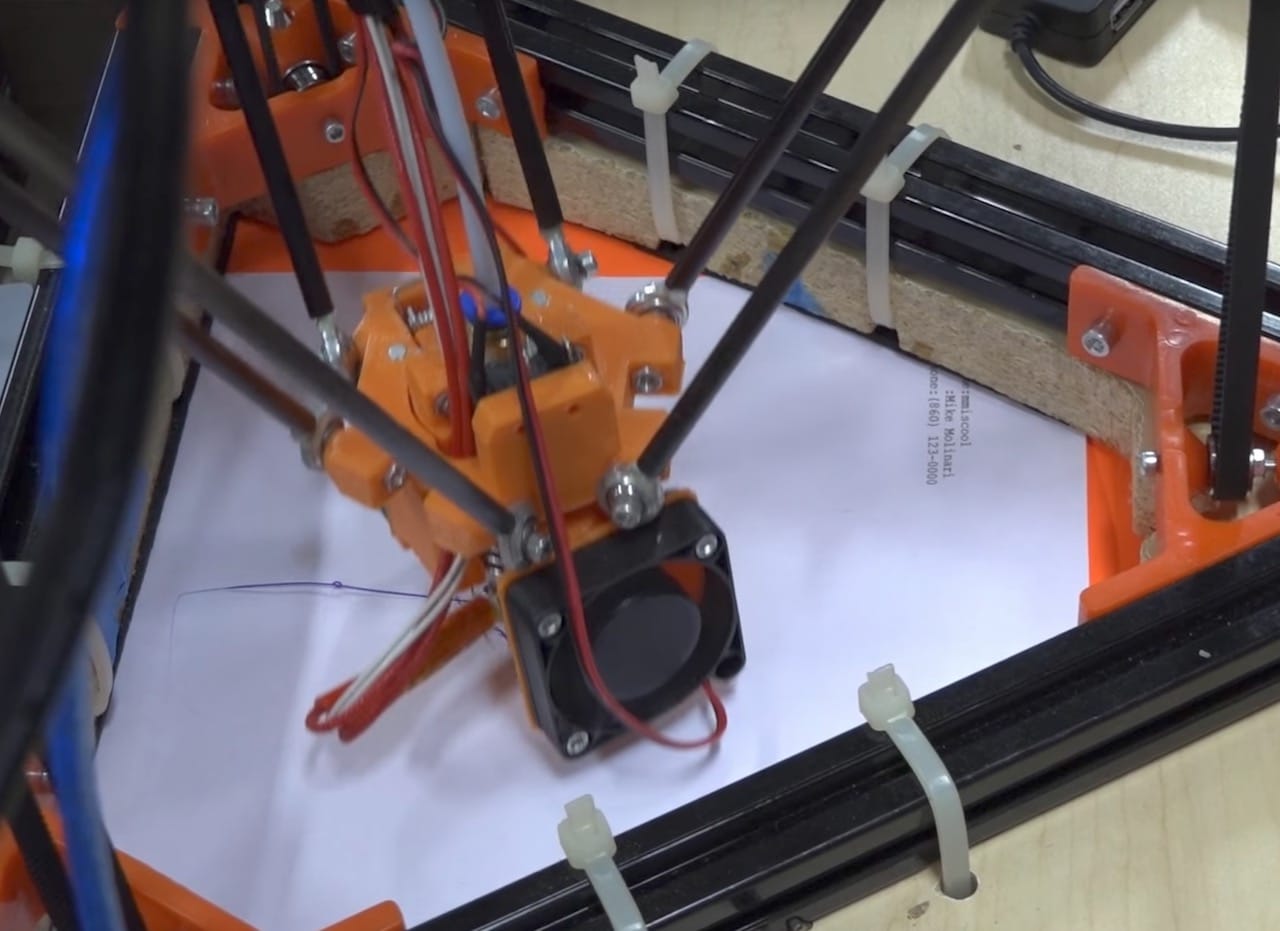

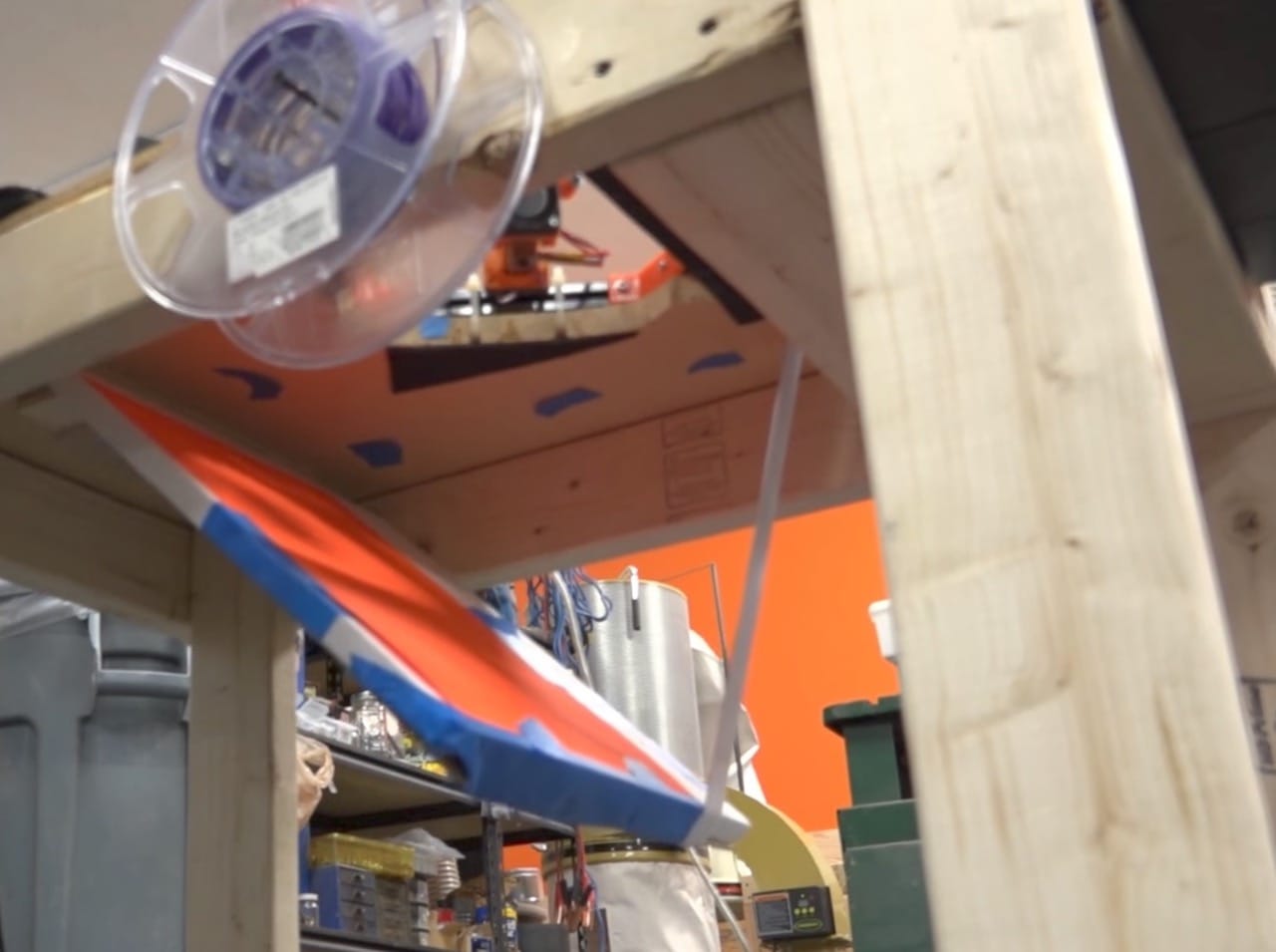

He’s combined a delta-style PLA desktop 3D printer with an inkjet printer to create an apparently functioning automated factory. Here’s how it works:

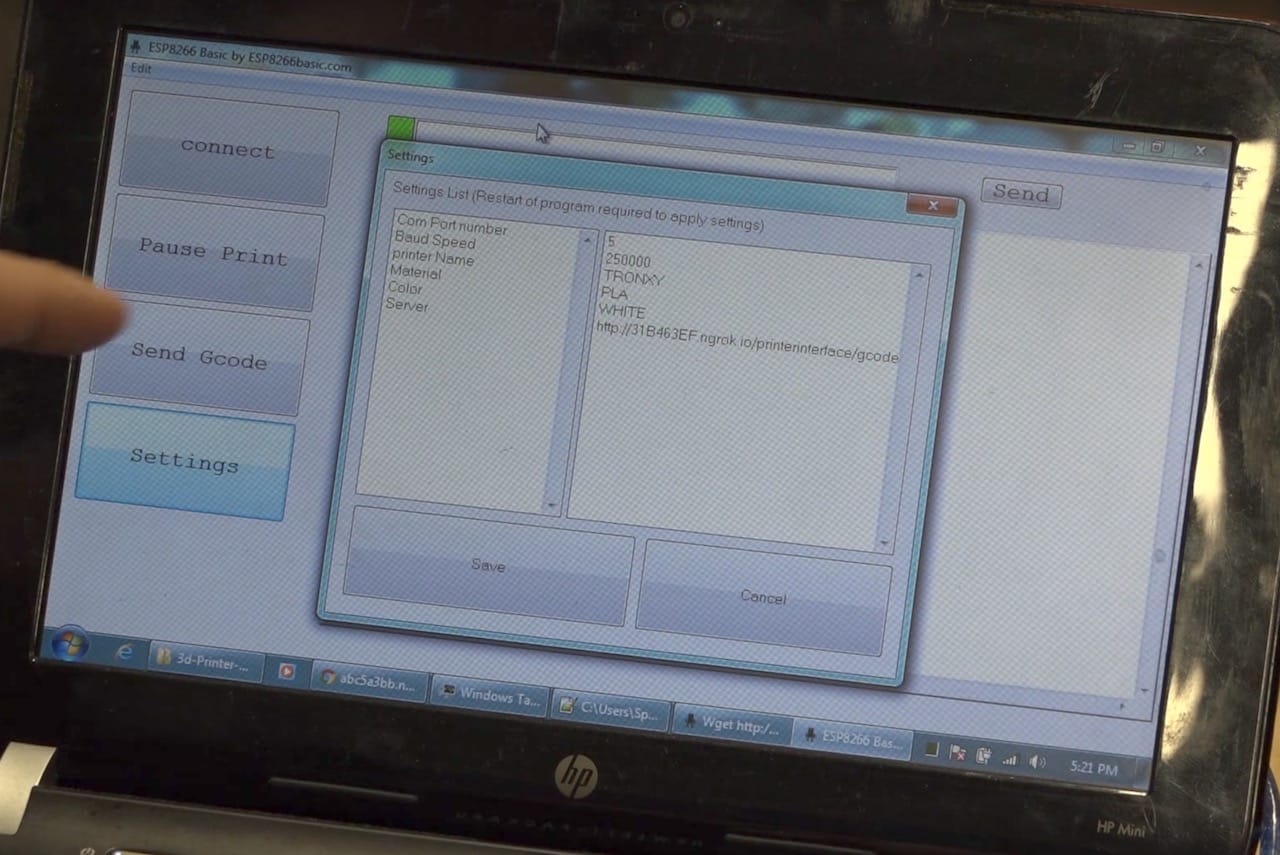

- A print job is dispatched from a custom software system

- The system sends meta-details about the job, like name, time, owner, etc to the inkjet printer

- The inkjet printer prints a single page of paper containing the meta details

- The printed page is shunted under the 3D printer

- A trap door closes up from below, trapping the paper flat

- The paper then becomes the print surface

- 3D printing commences, and the PLA plastic sticks to the paper

- At print completion, the trap door is released and the paper with attached print falls below, presumably into a bin

- The process repeats with a new piece of paper

To make this all work correctly, Molinari has developed a dispatch system that controls and coordinates the two printers, as well as the simple trap door mechanism (it’s a belt on a roller driven by another stepper motor).

The software slices 3D models and maintains a print queue, much like you would see on a paper 2D printer. This is not seen too often on 3D printers, as the concept of a queue is less meaningful when you have to manually switch out the build plate. But that’s not the case here. The build queue actually means something because it can literally be processed from beginning to end without operator involvement.

The system appears to work, and as such could be considered a factory that can repeatedly print objects.

Obviously, this is a very rough prototype, but it could portend a style of 3D printer that may become popular: a desktop factory.

I do have some concerns about the concept, however. I’m wondering about the leveling of the paper print bed; will it be level each and every time? I presume auto-leveling features of the delta 3D printer may assist, but this would have to work correctly countless times to be reliable.

The PLA plastic sticks to the paper. Is it easy to remove the paper from the bottom of the print? What about other plastics? Do they stick? Could an alternate paper-like, sheet-fed material be used for other plastics?

And the big question: what is the future for this concept? Will it be open sourced? Or turned into a product? Will Molinari do so? Or will this be an add-on feature for manufacturers of delta 3D printers.

Many questions, but the fact that we’re asking them means progress has occurred.

Via Hackaday