Startup Metafold is developing a way to 3D print large objects with highly complex geometries.

While super-complex objects have routinely been 3D printed at small scales, the prospect of doing them at scale has not been practical. The problem is that the geometric digital description of a large complex part is so voluminous that today’s processing software would choke when invoked.

This is why most large 3D prints have relatively simple geometries.

That’s unfortunate, because many of the advantages of 3D printing technology are due its ability to produce complex structures.

There are some efforts to overcome this dilemma, such as powerful processing boards, like Create It REAL’s, or unusual 3D representation algorithms such as nTopology’s.

However, none of these approaches is as sophisticated as Metafold’s. I spoke with Metafold’s CEO and co-founder, Dr. Elissa Ross, about the company and their work.

Metafold

Metafold is a brand-new startup that is a spinoff of MESH Consultants. MESH Consultants are a Toronto-based consultancy launched in 2012 focusing on mathematical problems for business. During their work they were exposed to 3D printing by way of engineering clients who happened to be using the technology to create metamaterials.

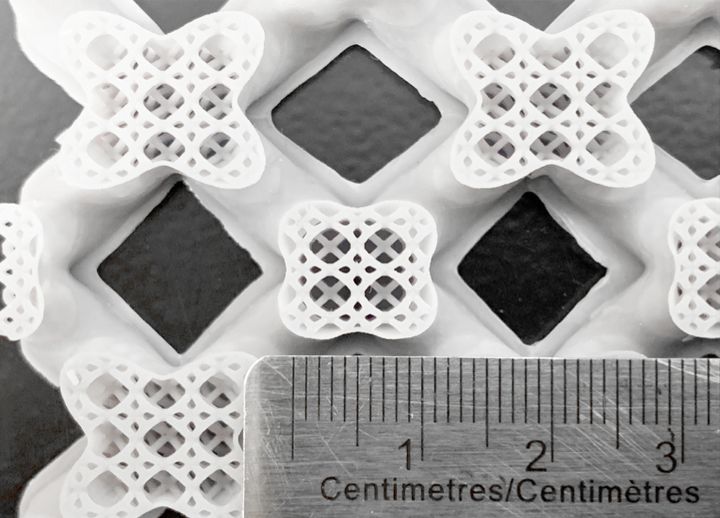

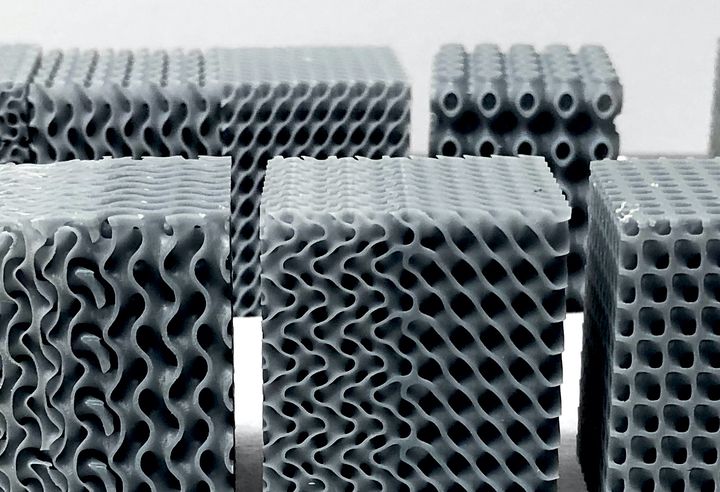

Metamaterials are structures made from one material but behave like others. For example, a lattice structure might act like soft foam, even though it is made from a solid material. There are an infinite number of possible metamaterials for many purposes. However, the design of metamaterials is a complex matter that requires significant mathematics and processing, hence MESH Consultants’ involvement.

During the pandemic their consulting business dropped off, and they were able to perform deeper research and development on ways to solve the problems they observed during the consulting engagements, and specifically these had to do with the current limitations of 3D printing systems. And by “systems”, I mean the software and hardware used to produce prints.

They formed a group that only this January finally incorporated as Metafold, and began to tell the story of their inventions to the public.

Metafold Capabilities

While much of their work is still behind closed doors, I can tell you this much:

- They’ve developed an integrated 3D printing system that includes both software and hardware elements

- The software is able to process vast and complex 3D models extremely efficiently and at great speed

- The 3D models are sliced IN REAL TIME for printing

- The integrated system can 3D print “millions of cells with no additional cost of time or memory”

- They’ve developed a prototype DLP-based resin 3D printer, the LightCycle, to integrate with the software

- The LightCycle currently offers a generous but not large build volume, but is of a design that can be scaled up much larger

- Scaling up can be done by simply moving the projector to different zones of the print area, using multiple projectors, or by continuously moving a projector

The implication here is that if Metafold succeeds, industry would have available a way to efficiently 3D print enormous complex structures. That’s so new I can’t even imagine how this capability could be used. Would it change aerospace? Architecture? Furniture? That’s a challenge that will be left to inventive Metafold clients of the future.

Design of complex structures like metamaterials is a matter of some importance in 3D printing these days, and I asked Dr. Ross how they approached the creation of these complex designs. Does Metafold have a library of metamaterial designs, for example?

It turns out they do not, and instead take an entirely different approach. It sounds a lot like generative design, where the designer merely specifies a number of starting conditions, and the software fills in the blanks by generating an appropriate — and likely complex — metamaterial structure.

I asked Dr. Ross whether the operators of their system would require notable mathematical skills, and she indicated that was not the case, but added:

“However, if you DO happen to have mathematical skills you can take our system to the next level.”

At this stage it’s still early for the new company, as they have reached the level of prototype machines. However, Dr. Ross says they are ready to perform pilot projects with academia or business.

As for the availability of the machine and software, it’s not ready yet. Their intention is to perform pilot tests and provide print services from their central location for a time to tune the software and hardware before releasing the product for direct purchase. Dr. Ross expects to have the product on the market sometime next year.

An important aspect of any startup is their funding, because without funding, any idea will falter. Metafold is currently funded by a seed investment from MESH Consultants, but it sounds like they are seeking additional investors.

If this idea is as good as it sounds, they’ll need plenty of investment to grow. Are you that investor?

Via Metafold