Charles R. Goulding and Peter Favata consider how 3D printing will come into play for Mercedes’ soon-to-be spun off truck division.

On February 3, 2021 Mercedes announced it will be spinning off its Daimler truck division. Daimler is a leader in creating energy-efficient trucks and buses. They will also be renaming the truck division Mercedes-Benz, which will be a separate public company from the car division. The restructuring move is meant to represent a reshaping of the company. Ola Kallenius, the chairman of the board for Mercedes-Benz ,was quoted as saying, “Mercedes-Benz Cars & Vans and Daimler Trucks & Buses are different businesses with specific customer groups, technology paths and capital needs”. The new truck company could have a value of about $35 billion.

Daimler has 6 different models of trucks:

- Mercedes-Benz Trucks – For medium-duty and heavy-duty

- BharatBenz Trucks – Developed for the Indian market

- FUSO Trucks – Producing light-, medium-, and heavy-duty trucks for the Asian market

- Freightliner Trucks – Weight classes 5 to 8 is the top-selling truck brand in North America

- Western Star – A premium North American manufacture of heavy-duty trucks for long-distance haulage

- Thomas Build Buses – High-quality buses for North America

Daimler’s new Mercedes-Benz GenH2, which is scheduled to begin trials by 2023, is designed to be a long-haul hydrogen fuel-cell that will fuel the truck with liquid hydrogen and has an estimated range of 621 miles and a payload of 25 tons. Daimler chose to use liquid hydrogen as opposed to gaseous hydrogen which is used in most fuel-cell vehicles. The reasoning behind this is liquid hydrogen has a greater energy density allowing for smaller fuel tanks.

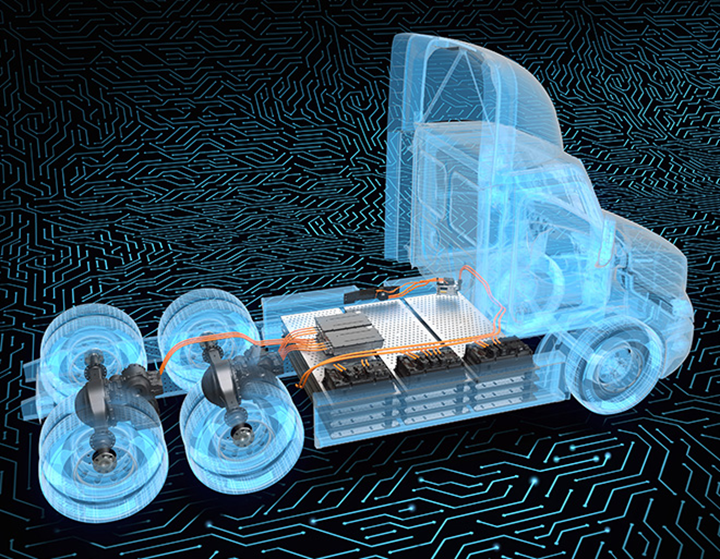

Electric Trucks

Daimler is also in the production of an electric truck named the eActros LongHaul. This battery-powered truck will have a range of about 310 miles on pure electricity, and with more truck stops adding electric vehicle chargers, these trucks will be able to travel cross-country. Other features include a self-driving aspect in order to keep accident numbers as low as possible.

Daimler’s upcoming electric trucks will be powered by its exclusive Detroit ePowertrain. The company has also announced its plans to invest $20 million in Detroit manufacturing facility. This will serve as the North American source of ePowertrain components.

3D Printing

3D printing has been used to help in the manufacturing and repair of semi-trucks. In January, we published an article on Fabbaloo describing how 3D printing truck parts improves the manufacturing process.

Utilizing 3D printing for truck parts will help in several ways. These include lower weight, spare parts on-demand, and tailored technology. The durable plastics that are used by 3D printers are much lighter than the normal metal parts that are used on trucks. This combined with metal 3D printing will also benefit the truck sector. 3D printers can be installed into garages to print aftermarket parts on demand. As far as tailored technology 3D printing is extremely useful for producing parts that are no longer in production and difficult to find on the aftermarket.

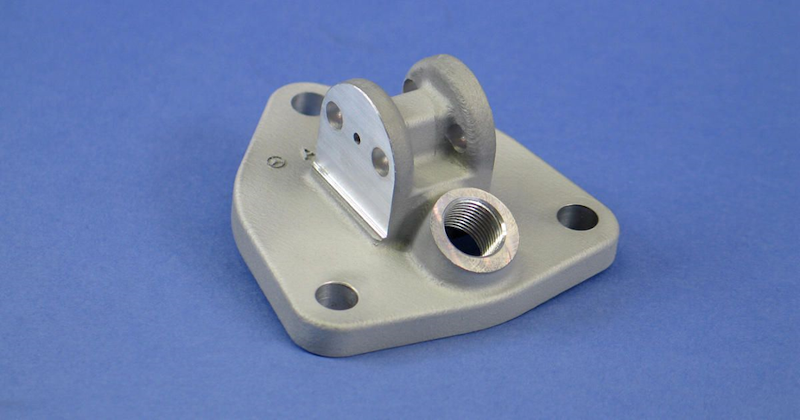

Daimler has utilized additive manufacturing for truck parts in the past. In 2017, the company began using metal 3D printing for spare parts. In 2019, Daimler made a large investment in automated 3D metal printing. They were able to create a diesel engine component cheaper and faster than traditional manufacturing methods. Below is an image of this component:

Manufactures and technical designers utilizing additive manufacturing may be eligible for Research and Development (R&D) Tax Credits.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit can be used to offset Alternative Minimum Tax (AMT) or companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in cash rebates that can be applied directly to payroll taxes.

Conclusion

Mercedes is spinning off its truck division at a time when many new technologies are being introduced for trucks. As things continue, Mercedes’ truck business will be encouraged to implement the specific technologies it wants, 3D printing included.