Charles R. Goulding and Preeti Sulibhavi believe there is a key role for 3D printing in the Ukraine conflict.

There is an international battle going on for military tanks. It seems like a paradox, but it is true. German-made Leopard tanks were requested by the Ukrainian government. UK Prime Minister, Rishi Sunak, promised to provide its Challenger 2 tanks and artillery systems to Ukraine amidst and escalation in fighting. Finland and Poland have both indicated they would like to send their Leopards to Kyiv, and very recently, Germany has granted permission to do so.

This is because the Leopard tanks are German-built and according to the agreements, Germany must give express permission for any country to transfer or release the tanks to another country. The Ukrainian request has recently been approved by Germany, and it will be sending 2 Leopard tanks to Ukraine.

Similarly, the Abrams battle tank is an American-made war machine that only America can release to other countries or authorize the release of them. The US has just decided to provide Ukraine with 31 M1 Abrams tanks. That is the required number to equip an entire Ukraine tank battalion.

3D Printing and Combat Equipment

The use of 3D printing technology in combat equipment is not entirely new. However, its relevance in this situation is more obvious.

For battle tanks, in general, the following components are required:

- Tracks

- Internal combustion engine

- Hull

- Hatch

- Turret

- Armor

- Guns

When first generation tanks were designed and built, 3D printing for metal components was in its experimental stages, if in existence at all. Now, the technology has advanced considerably and the use of 3D printing for battle tank components is a possibility.

The Abrams tanks are complex and require substantial training to operate and field support to maintain.

The Abrams tanks approved for Ukraine must be built and this will be an ideal time to create a digital twin as has been done with the Black Hawk helicopter.

Digital twins for both the Abrams and the Leopard tanks will facilitate future 3D printed part replacement.

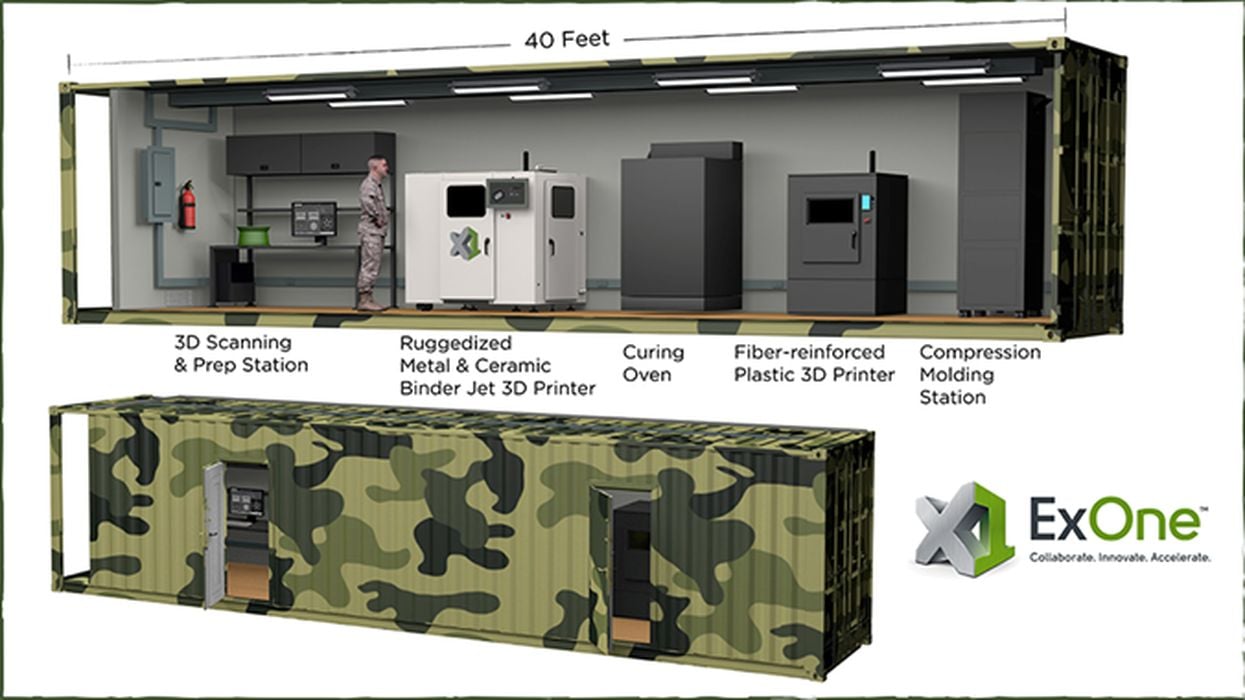

We have covered how the US Army is using 3D printing in one of our recent Fabbaloo pieces. We showed how 3D printing in a portable container that can be deployed as needed has been in popular demand in the Army in recent years. One large-format 3D printer is itself also made in a shipping container. The ExOne solution offers an interesting binder jetting angle to the idea.

In 2021, we covered ExOne’s US$1.6M Department of Defense (DoD) contract for portable 3D printing. These shipping containers/portable 3D printing factories allow movement and flexibility in the field.

A recent Politico article revealed that German tanks are “kaput.” During a military exercise in December 2022, a German tank brigade was being prepared for NATO’s “high readiness” response force and all 18 of the modern German infantry fighting vehicles failed, with everything from electronic to turret defects. “Even with the best preparations, the question of the vehicles’ readiness has become a game of lottery,” Major General Ruprecht von Butler wrote his boss, according to a copy of the email quoted by Der Spiegel recently.

There is no reason why 3D printing technology cannot be used to help rectify at least some of these issues, as well as get Ukraine to combat readiness.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Now that the Abrams and Leopard tanks are authorized for transport to Ukraine, 3D printing can help maintain these valuable pieces of equipment and help repair and replace many damaged parts in real-time.