Charles R. Goulding and Preeti Sulibhavi consider potential 3D printing implications from a major merger in the North American rail industry.

The proposed merger of the Canadian National Railway (CN) and Kansas City Southern (KCS) will create a tri-country (Canada, U.S., Mexico) rail network connecting major ports and facilitating the shipment of goods from Detroit to Laredo.

The CN is an extensive railway that spans 20,000 miles from Canada to mid-America connecting three coasts – the Atlantic, Pacific and Gulf of Mexico. CN is a cornerstone of the economy whose team of approximately 24,000 railroaders transports more than C$250 billion worth of goods annually for a wide range of business sectors, ranging from resource products to manufactured products to consumer goods, across an expansive rail network.

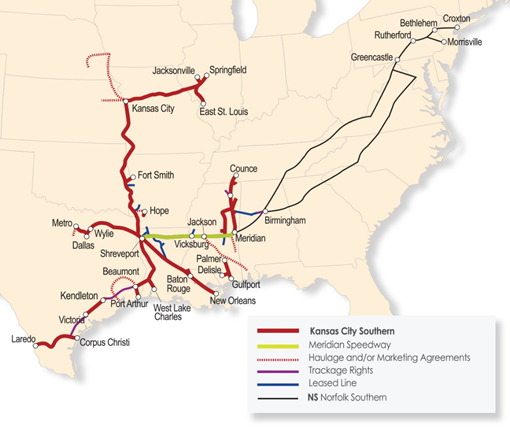

KCS strives to consistently be the fastest-growing, best-performing, most customer-focused transportation provider in North America. Founded in 1887, it operates in ten midwestern and southeastern U.S. states. KCS hauls freight for seven major government and business sectors: agriculture and minerals, military, automotive, chemical and petroleum, energy, industrial, and consumer products and intermodal.

KCS has the shortest north-south rail route between Kansas City, Missouri and several key ports along the Gulf of Mexico in Alabama, Louisiana, Mississippi and Texas. The KCS, along with the Union Pacific railroad, are the only two Class I railroads based in the United States.

The company owns or contracts with inter-modal facilities along its rail network. KCS operates over a railroad system consisting of 3,400 route miles that extend south to the Mexico-United States border. Its sister company, Kansas City Southern de México (KCSM), can haul freight into northeastern and central Mexico and to the Gulf of Mexico ports of Tampico, Altamira, and Veracruz, as well as to the Pacific Port of Lázaro Cárdenas.

In addition to shortening shipment times, this merger will reduce truck shipments and missions. Rail is a much more energy-efficient mode of transportation than trucking. The new connected continent should improve the overall Midwest economy – including the 3D printing community, which has a deep Midwest concentration. The new network will be able to leverage rail 3D printing technology for parts and repairs. Multinational benchmarking should greatly assist this endeavor.

For example, the French national railway created a software system to manage the wide variety of 3D printing repair parts needed to service a wide range of rail equipment categories including older components that are no longer manufactured by Original Equipment Manufacturers (OEMs) and or parts that are difficult to find. In a previous article we authored, Mobility Goes Additive for RAIL-iability in 3D Printing, we described the 120 rail industry market participants that are focused on 3D printing for the European rail industry. The new CN-KSA North American combination should be able to greatly benefit from the accomplishments of this large-scale, multinational European effort.

Rail is one of the oldest and most effective ways to transport people and cargo. This merger should not be overlooked as an opportunity for the 3D printing industry to add value and take advantage of an opportunity presenting itself.

The Research & Development Tax Credit

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

A “Rail” Solution

Seamless rail transportation from Canada through the US to Mexico should increase commerce for all three countries. The U.S. 3D printing industry should be able to further improve the potential efficiencies for North America.